The strength of gray cast iron depends on the type of graphite and matrix structure in its microstructure. When the matrix structure is the same, the number, shape, size and distribution of graphite have a great impact on the mechanical properties of cast iron. The more the number, size and distribution of graphite sheets in gray cast iron, the greater the impact on the mechanical properties.

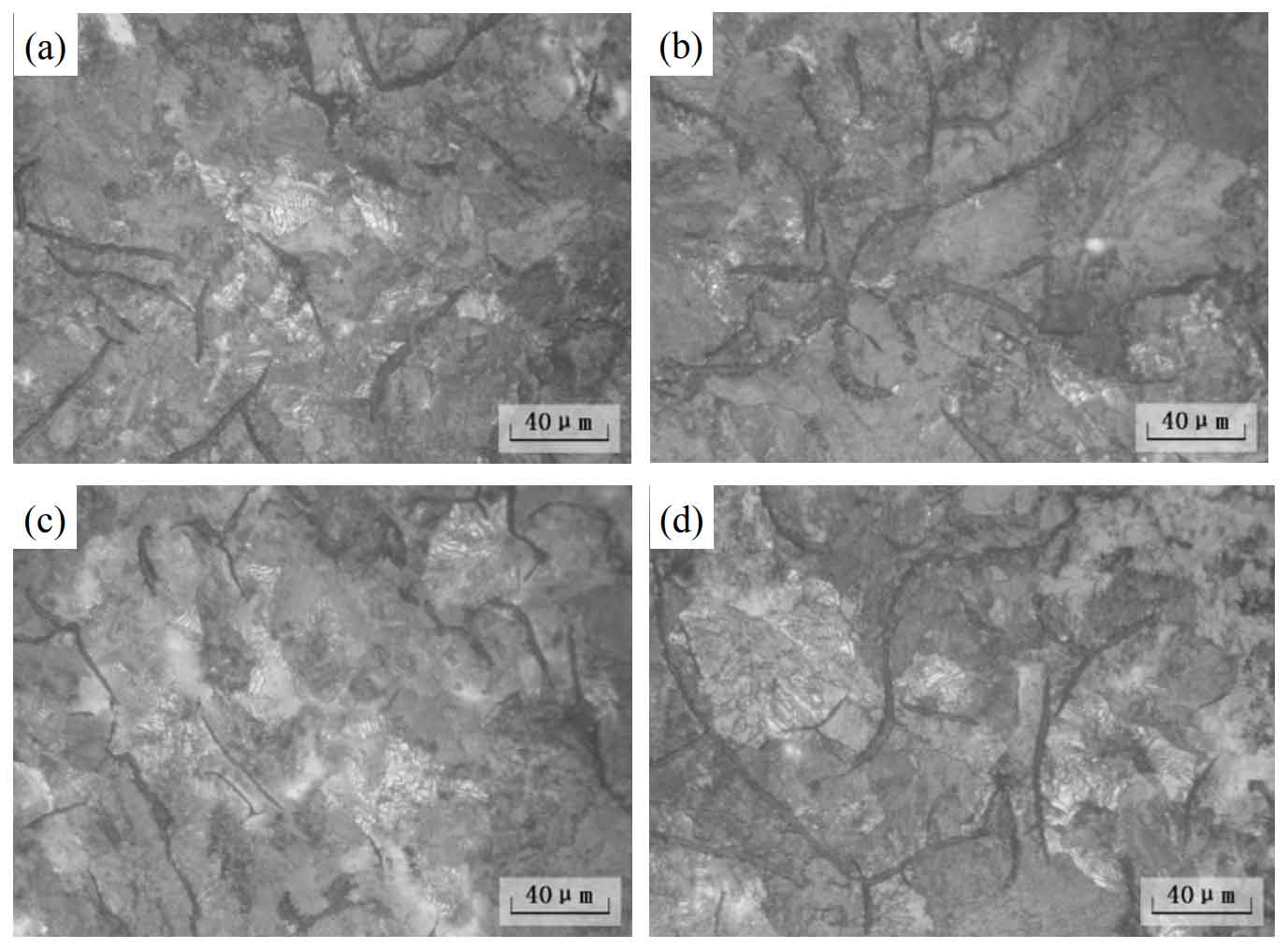

The graphite morphology of gray cast iron treated with four inoculants is shown in Figure 1. As can be seen from Figure 1, the graphite morphology of the four samples is basically dominated by type a graphite, and type D graphite occasionally appears in some areas. The size and distribution of type a graphite sheet are relatively uniform and non directional. It is the most common graphite form. The mechanical properties of gray cast iron with this graphite form are the best, and other types of graphite will reduce the mechanical properties and cutting properties of cast iron to varying degrees. D-type graphite precipitates in the form of symbiotic growth, which is different from A-type graphite precipitated in the form of primary precipitates. The end of D-type graphite is blunt, the graphite sheet is bent, and its matrix has high mechanical properties. In Figure 5-1 (d), the graphite has the shortest length, fine shape, bending and most uniform distribution; Figure 1 (c) the graphite has smooth shape, long length and blunt end. In the cutting process of gray cast iron, the fine and uniform graphite structure can improve the deformation of chips, reduce the friction force and wear area of tools, and improve the cutting life of tools.

Fig. 2 is a photograph of the matrix structure of four groups of gray cast iron. It can be seen from the figure that the matrix structure of gray cast iron obtained in this study is basically the same, which is 95% pearlite matrix. Inoculant can promote graphitization, refine grains and reduce the content of free ferrite during solidification of gray cast iron, so as to improve the microstructure of gray cast iron castings. The flake spacing, lamellar structure and carbide size of pearlite in gray cast iron treated with different inoculation are different. By observing the pearlite sheet spacing in Figure 2, it can be seen that the pearlite sheet spacing in Figure 5-1 (d) is uniform, and there is trace ferrite in some areas, so the cutting resistance of sample 4 in the cutting sample is the smallest.