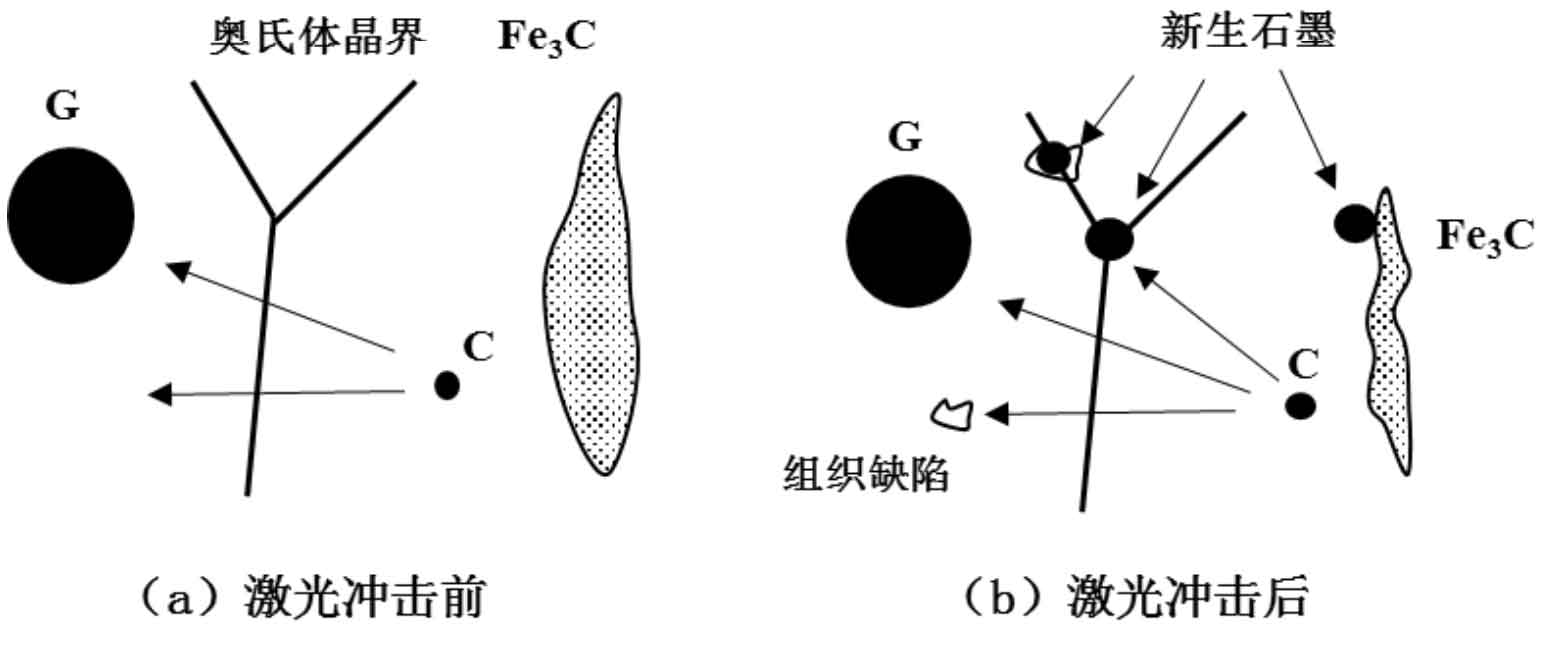

The nucleation and growth of gray cast iron graphite are gradually formed during heating. The nucleation position of gray cast iron graphite is most likely to occur around unmelted graphite and micro defects in the structure. The volume expansion of gray cast iron graphite in the nucleation process is relatively large, but due to the high hardness of cementite around gray cast iron graphite, it hinders the nucleation and growth of gray cast iron graphite. Therefore, the nucleation of new graphite is mostly located at the internal defects of austenite grains. When gray cast iron graphite nucleates at the austenite grain boundary, their growth direction is limited by the austenite grain boundary, and the amount of nucleated gray cast iron graphite is also small.

After graphitization annealing of gray cast iron after laser shock, the precipitated graphite can nucleate in situ on the austenite grain boundary or at the decomposition position of cementite. Because a large number of defects such as dislocation accumulation and micro holes are produced in the microstructure of the melting layer of gray cast iron after laser impact, which creates favorable conditions for graphitization nucleation, as shown in the figure. When the graphite of gray cast iron is in dislocation and nucleation on micro pores, it is not necessary to replace iron atoms or other elements, but only to carry out the aggregation process of carbon atoms. In the process of carbon atom aggregation, the carbon atoms precipitated from austenite are displaced by virtue of the vacancy between cementite lamellae, and the dislocation existing on austenite grain boundary improves the power of carbon atom diffusion nucleation, thus accelerating the nucleation process of gray cast iron graphite. Laser shock treatment of gray cast iron increases the number of graphite nucleation, promotes the heterogeneous nucleation process of graphite, and then improves the nucleation rate of graphite. When the gray cast iron graphite grows at the micro hole in the laser melting impact layer, the volume expansion is not restricted by the cementite dendrite, and the shape of the growing gray cast iron graphite is better.