The mechanical properties of nodular cast iron mainly depend on the matrix structure of nodular cast iron. At the same time, the shape, size, quantity and distribution of graphite balls also play an important role in the mechanical properties of nodular cast iron.

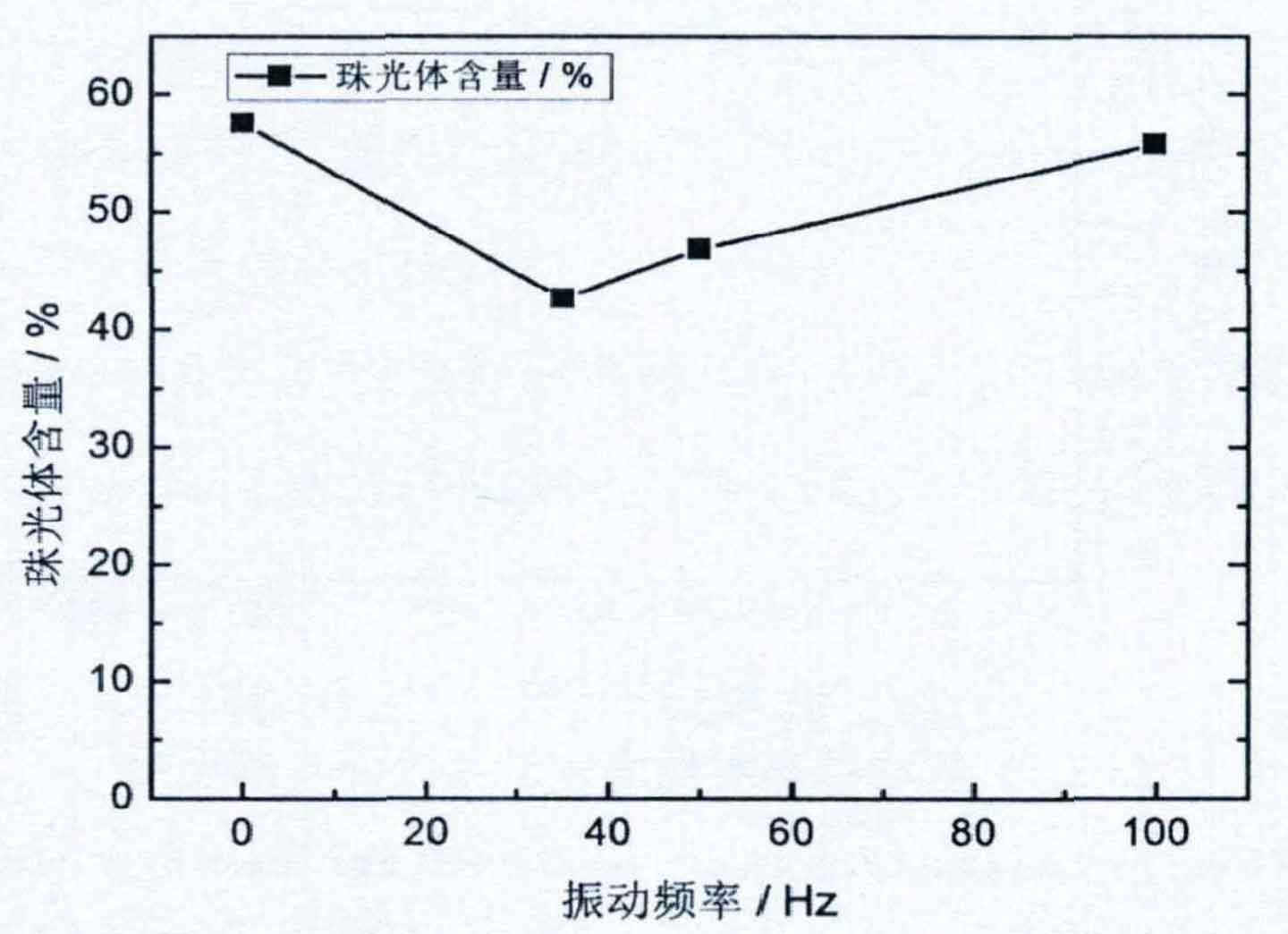

The matrix structure is the most important factor affecting the tensile strength of nodular cast iron. The higher the pearlite content in the matrix structure of nodular cast iron and the smaller the pearlite sheet spacing, the higher the tensile strength and the lower the elongation of nodular cast iron. On the contrary, the lower the tensile strength and the higher the elongation of nodular cast iron.

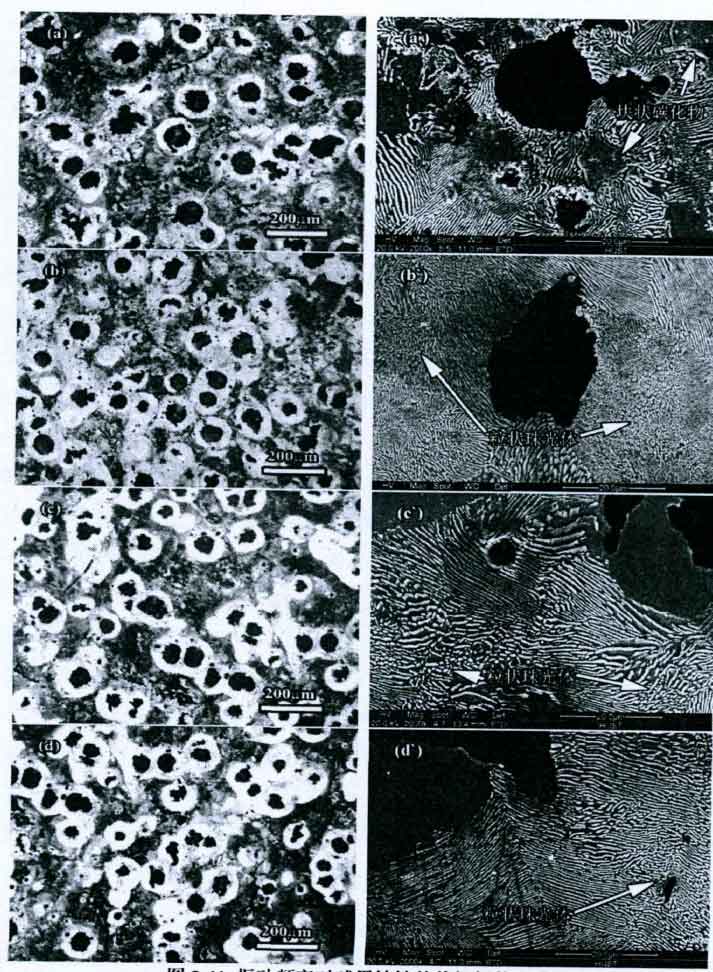

It can be seen from Figure 1 and Figure 2 that the pearlite flake spacing of nodular cast iron prepared under the condition of vibration frequency of 35Hz is the smallest, and a large amount of granular pearlite is distributed in the structure of nodular cast iron. When the metal is subjected to external force, the carbides in the granular pearlite will have a pinning effect on the plastic deformation of the metal, making the deformation of the casting difficult. In addition, the pearlitic structure with small spacing between sheets will also improve the matrix strength of nodular cast iron, which is the main reason for the high tensile strength of nodular cast iron prepared by this process.

In addition, it can be seen from the above analysis that the content of pearlite in nodular cast iron prepared under the condition of vibration frequency of 35Hz is low, and there is a large amount of granular pearlite in pearlite, which will greatly improve the shaping of the alloy, that is, the elongation of nodular cast iron is high. However, the tensile strength of the cast iron is lower because the pearlite flake spacing in the nodular cast iron prepared at the vibration frequency of 50Hz and 100Hz is larger than that in the nodular cast iron prepared at the vibration frequency of 35Hz. However, in the lost foam casting ductile iron without vibration, the content of natural pearlite is high. However, due to the existence of more massive carbides in the ductile iron obtained by this process, the tensile strength and elongation of the ductile iron are greatly reduced, resulting in the brittle fracture of the ductile iron.