The effect of checking the riser mainly includes the check of feeding range and feeding weight. One method to calculate the feeding distance in the horizontal direction of the riser is the riser continuity method. Riser continuity refers to the ratio of the sum of riser root dimensions to the length of sand castings in the same direction, and the distance between each two risers should be equal. The continuity of riser depends on the thickness of sand casting, which is generally;

(1) When the thickness of sand casting is ≤ 100mm, the continuity is 38% – 40%;

(2) When the thickness of sand casting is more than 100-150mm, the continuity is 35% – 38%;

(3) When the thickness of sand casting is greater than 150mm, the continuity shall be 30% – 35%.

(4) Placing cold iron at the end of sand casting can increase the feeding distance of riser, and the feeding distance of riser in vertical direction is close to that in horizontal direction.

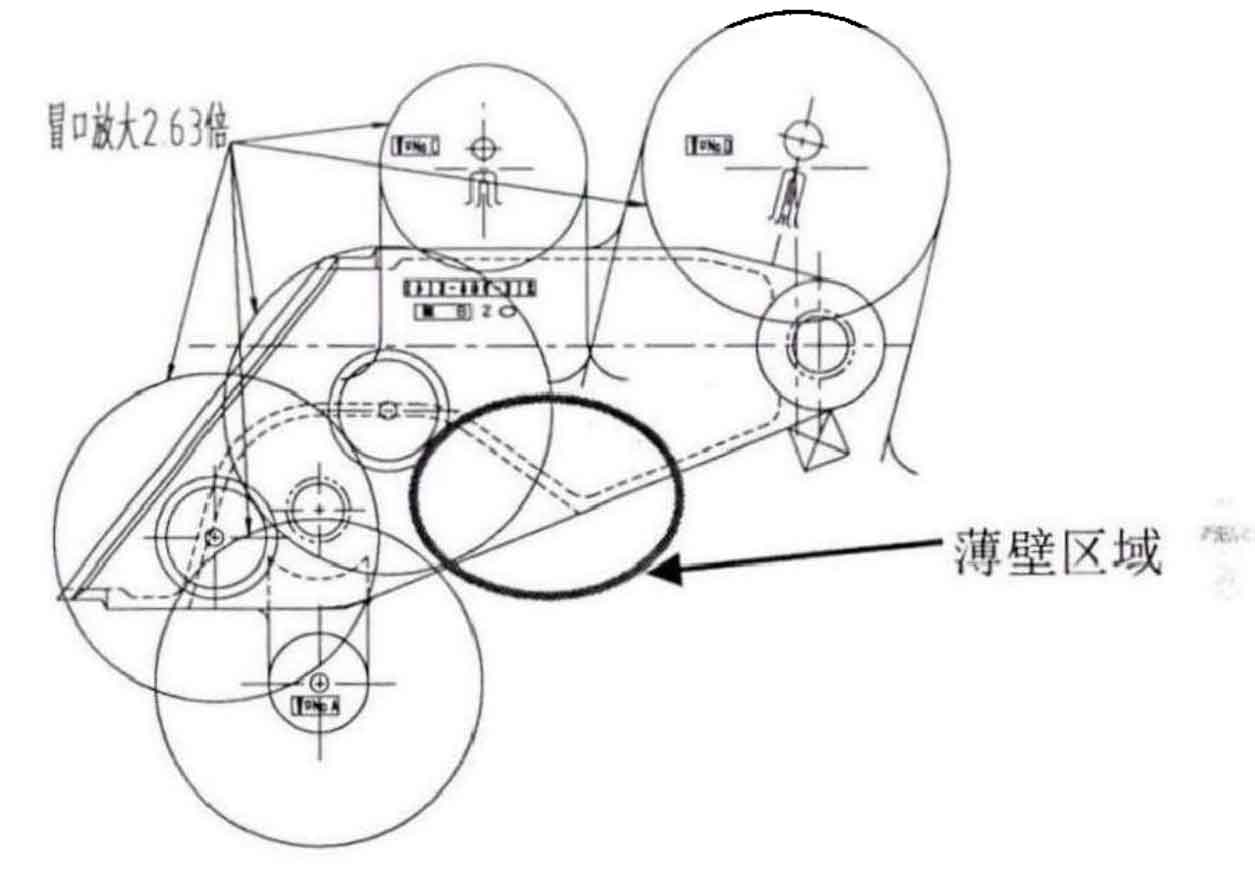

As shown in Figure 1 and Figure 2, the wall thickness of all parts of product k141 does not exceed 100mm, so it is conservative to take 38% of the riser continuity. Amplify the set riser, and the magnification is (0.38) – 1, that is, 2.63 times. The range that the riser can be fed and shrunk after amplification is shown in Figure 3. It can be seen from the figure that most sand castings can be covered after being enlarged. The uncovered area does not need feeding because there is chilled iron for quenching, or because it is a thin-walled area. Therefore, it can be concluded that the feeding range of riser meets the requirements.