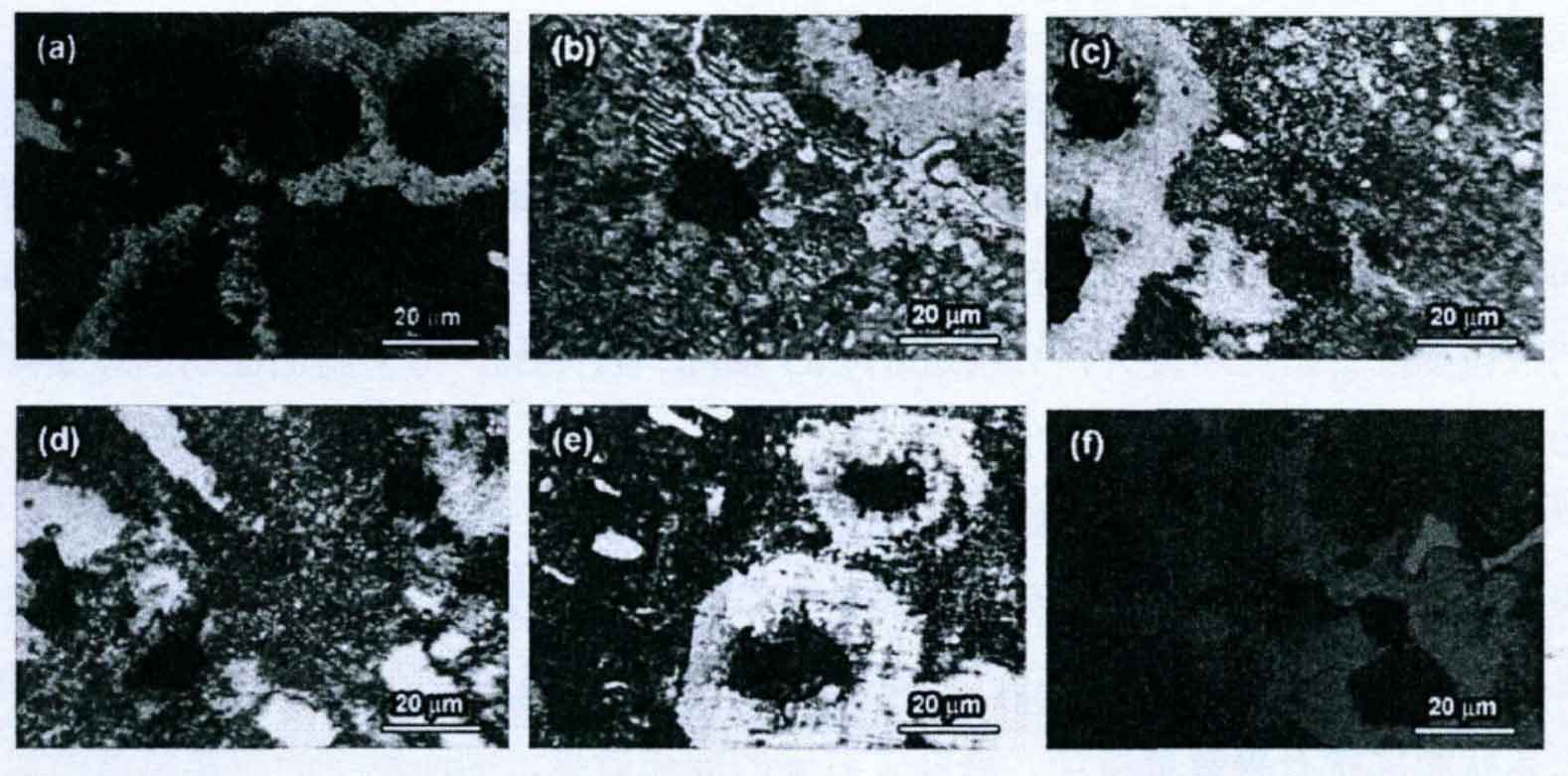

The figure is the matrix structure diagram of the vibration lost foam casting ductile iron, in which figures (a) – (f) are the matrix structure of the samples with wall thickness of 10, 20, 30, 40, 50 and 60mm respectively. It can be seen from the figure that the matrix structure of vibration lost foam casting nodular cast iron is composed of pearlite + spheroidal graphite + ferrite, in which spheroidal graphite and ferrite constitute a typical “ox eye” structure. According to the views of xujinfeng and other scholars, when the temperature of solidified molten iron decreases to a certain value, spheroidal graphite will precipitate from the molten iron and grow independently, forming a carbon escape zone around the spheroidal graphite, extremely carbon poor in the area close to the graphite, and finally forming an austenitic shell. When mechanical vibration is applied during solidification of molten iron, the heat transfer and convection in the metal body are accelerated, the temperature gradient in the casting is reduced, and the crystal nucleation in the metal melt and the sealing rate of some austenite halos before eutectic transformation are slowed down.

In addition, the number of “ox eye” structure in nodular cast iron reflects the change of the number of eutectic grains to some extent, that is, the increase of the number of “ox eye” structure will increase the number of eutectic grains in nodular cast iron. As the cooling speed of the sample with small wall thickness is faster, the “viscous shear” effect of vibration on the metal solution is smaller, and the degree of particle dissociation and proliferation is smaller, resulting in the reduction of the number of eutectic grains. When the sample wall thickness increases, especially when the sample wall thickness reaches 60mm, due to the increase of the volume of the casting, the heat storage released during solidification increases, which reduces the cooling rate of the casting and prolongs the action time of vibration on the metal solution and the solid-liquid mixing zone, As a result, the action time of “viscous shear” on the metal solution and solid-liquid mixing zone in the metal solidification process is prolonged, and the number of free fine grains in the sample is increased. Part of the free fine grains can be used as the heterogeneous nucleation substrate for metal flame crystallization, which increases the number of heterogeneous nucleation in the flame and reduces the final size of eutectic grains.