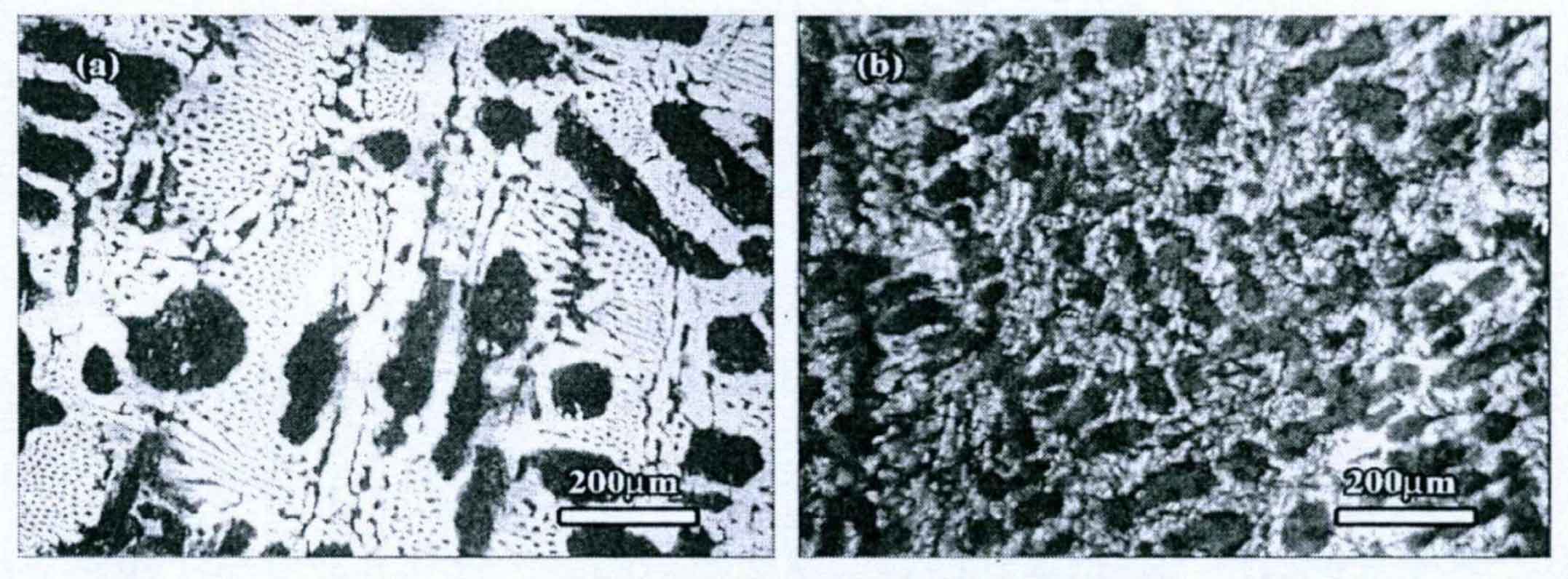

The picture shows the microstructure of white cast iron in lost foam casting with and without vibration. It can be seen from the figure that in the lost foam casting white cast iron without vibration, the grain size of primary austenite is relatively large and its content is small. According to the software statistics, the content of primary austenite in the white cast iron obtained by this process is about.

However, in the white cast iron prepared with the vibration frequency of 35Hz, the content of primary austenite is more and the austenite grain size is smaller, which is about 55.1%. Compared with lost foam casting white cast iron without vibration, it increased by 47.33%.

The effect of vibration on the microstructure of white cast iron is a topic of interest in materials science and metallurgy. White cast iron is characterized by its hard, brittle nature, primarily due to the presence of cementite (iron carbide) in its microstructure, as opposed to the graphite flakes found in grey cast iron. Understanding the impact of vibration on its microstructure involves examining how vibration can influence the formation and distribution of these microstructural constituents.

Effects of Vibration on White Cast Iron Microstructure

- Modification of Cementite Formation:

- Vibration during the solidification process can affect the way cementite forms in white cast iron. It can potentially lead to a finer and more uniform distribution of cementite, altering the material’s hardness and brittleness.

- Refinement of Grain Structure:

- Vibrations can lead to grain refinement in the cast metal. Finer grains typically result in improved mechanical properties, such as higher strength and toughness.

- Influence on Solidification Process:

- The solidification rate may be affected by vibration. A faster cooling rate, often influenced by vibration, might promote the formation of a more ledeburitic microstructure (a mix of cementite and pearlite in white cast iron).

- Potential Reduction in Defects:

- Vibration can help in reducing casting defects like porosity and segregation. This leads to a more homogenous microstructure, which can enhance the overall properties of the cast iron.

- Impact on Stress Distribution:

- Uniform distribution of stress and minimization of stress concentrations can be facilitated by vibration. This may lead to improved overall performance of the material under load.

Considerations and Limitations

- Controlled Vibration Parameters: The frequency and amplitude of vibration need to be carefully controlled to achieve the desired effects. Over or under-vibrating can lead to adverse effects on the microstructure.

- Complex Interplay of Factors: The impact of vibration on microstructure is influenced by several factors, including composition, temperature, and cooling rate, making it a complex process to manage.

- Equipment and Process Challenges: Implementing vibration during casting can require specialized equipment and may introduce challenges in the casting process control.

Conclusion

While the influence of vibration on the microstructure of white cast iron can be significant, leading to potential improvements in mechanical properties, it’s a complex process that requires careful control and understanding. Research in this area continues to evolve, offering the potential to fine-tune the properties of white cast iron for specific applications through controlled application of vibration during the casting process.