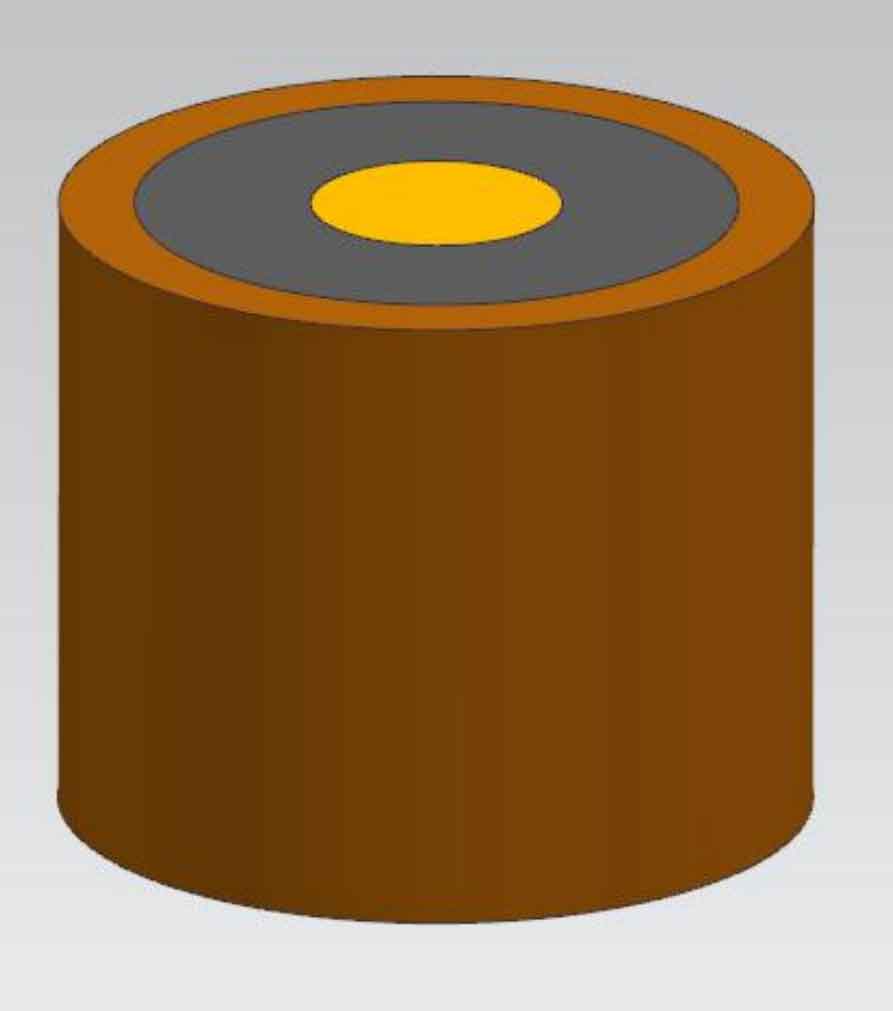

In order to make the simulation results compare with the measured temperature curve, the established geometric model should be the same as the test model. The annular sand castings with internal and external radius of 60 / 110mm are selected for the simulation verification test, with thickness of 50mm and height of 150mm. After the casting is modeled as a three-dimensional sand mold by Parasolid, it can be recognized by Parasolid software_ T file, as shown in Figure 1, is the geometric model of sand casting.

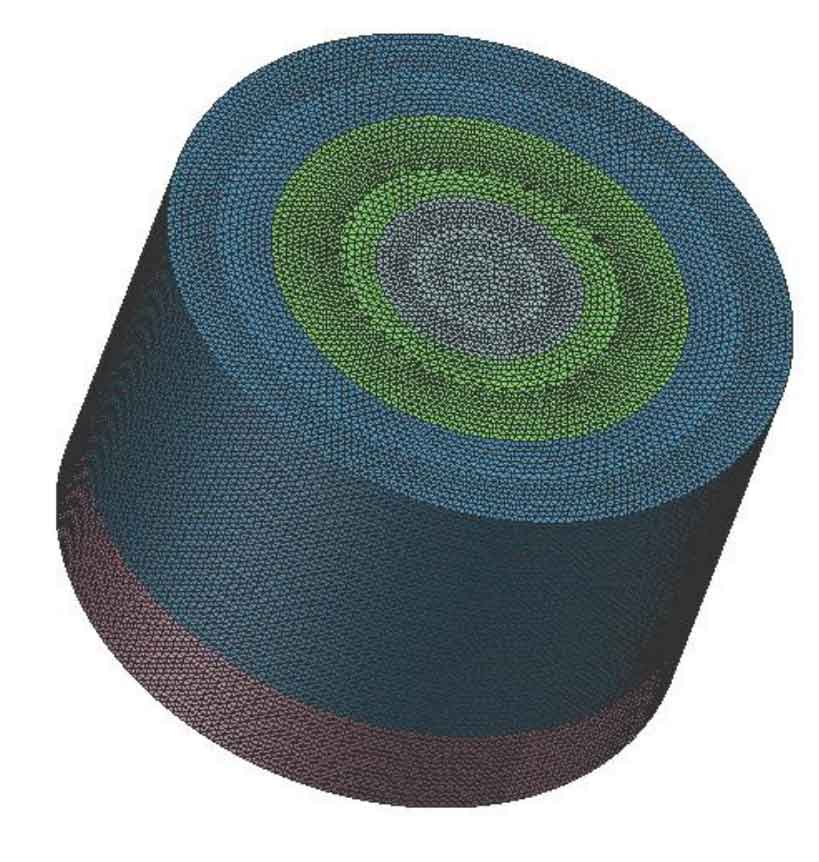

After the geometric model is exported, import the three-dimensional model file into the visual mesh interface of ProCAST simulation software, assemble the sand casting and mold through the assembly function in the geometric structure, and then divide the surface mesh and volume mesh. In order to match the simulation results with the inverse calculation process, the step size of the inverse calculation process is consistent, and the two-dimensional mesh size is set to 4mm. After the two-dimensional mesh is checked, the three-dimensional volume mesh is divided and checked. Figure 2 shows the volume meshing results of the simulation model.

The grid number of 60 / 110mm ring sand casting is 980680. After the completion of grid division, the grid shall be checked and repaired, and the simulation pretreatment shall be carried out after the body grid is checked to be correct.