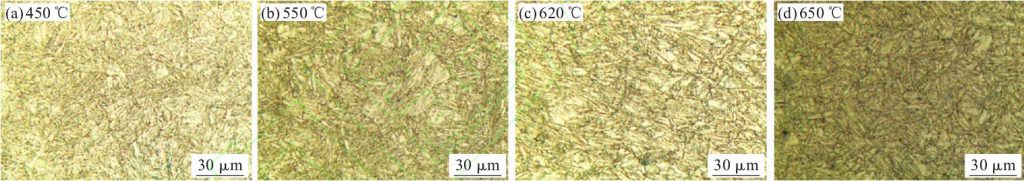

Figure 1 shows the metallographic structure of the steel tested after tempering at different temperatures. It can be seen from the figure that, although the tempering temperature is high, the microstructure after tempering at 450, 550, 620 and 650 ℃ is still sheet strip tempered martensite + a small amount of retained austenite + a small amount of granular carbide.

Figure 2 shows the effect of tempering temperature on hardness and impact work of the test steel. It can be seen from Figure 2 that the hardness of the test steel is generally decreasing with the increase of tempering temperature. However, the hardness of the test steel is the highest at 550 ℃, which is 40HRC, and secondary hardening occurs. It can be seen from Figure 2 that with the increase of tempering temperature, the impact work of the test steel will decrease, rise and decrease again and rise. After tempering temperature ≥ 600 ℃, the impact work of the test steel will rise, and the impact work at tempering temperature of 500 ℃ is obviously the lowest.

In order to further explore the mechanical properties of the steel, tensile test was carried out, and the tensile properties of the steel were tested at different tempering temperatures. With the increase of tempering temperature, the strength of the test steel decreases gradually, and the elongation after fracture increases gradually, which conforms to the change rule of the mechanical properties of the low carbon alloy steel after tempering.