Spheroidal Graphite Iron, also known as ductile iron or nodular iron, is a type of cast iron that has gained significant popularity and widespread use in modern engineering applications. It offers several advantages over other materials, making it a preferred choice in various industries. Let’s explore some of the key advantages of Spheroidal Graphite Iron:

- High Strength: Spheroidal Graphite Iron possesses excellent mechanical properties, including high tensile strength, yield strength, and impact resistance. It can handle heavy loads and is less likely to fracture or fail under stress compared to conventional gray cast iron. This high strength makes Spheroidal Graphite Iron suitable for applications where structural integrity and load-bearing capacity are critical.

- Ductility: Unlike brittle cast irons, Spheroidal Graphite Iron exhibits good ductility, meaning it can undergo plastic deformation without fracturing. This property makes it highly resistant to cracking or breaking when subjected to sudden shocks, vibrations, or impact loads. The ductility of Spheroidal Graphite Iron ensures that it can withstand demanding operating conditions and provides a safety margin against catastrophic failures.

- Thermal Conductivity and Thermal Expansion: Spheroidal Graphite Iron has relatively high thermal conductivity compared to other cast metals, which allows for efficient heat dissipation. This property is especially advantageous in applications where temperature control is crucial, such as engine components, brake systems, and heat exchangers. Additionally, Spheroidal Graphite Iron has a moderate coefficient of thermal expansion, reducing the risk of thermal stresses and associated failures in various thermal cycling applications.

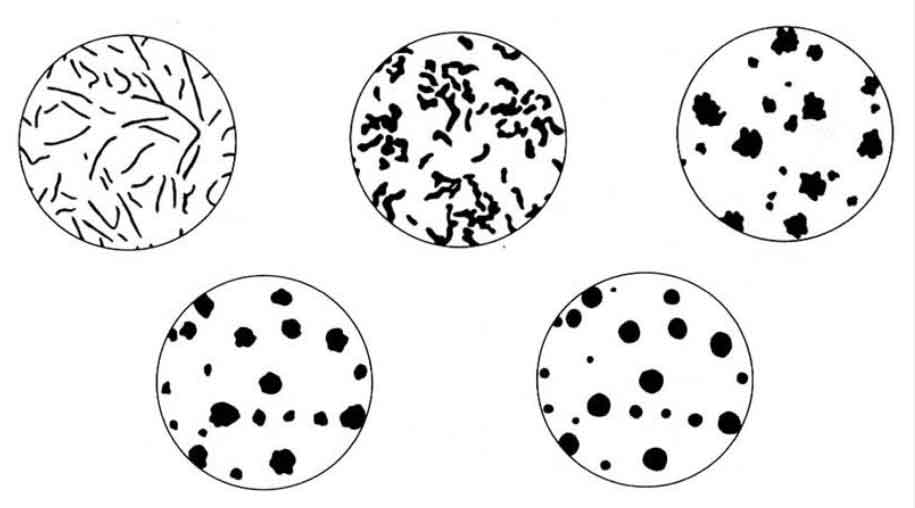

- Wear Resistance: Spheroidal Graphite Iron exhibits excellent wear resistance due to the presence of graphite nodules in its microstructure. The graphite acts as a solid lubricant, reducing friction and wear between surfaces in sliding or rotating applications. As a result, Spheroidal Graphite Iron components can withstand abrasive environments, such as in pumps, valves, gears, and automotive components, leading to longer service life and reduced maintenance costs.

- Machinability: Spheroidal Graphite Iron has good machinability, making it easier to shape and form into intricate components. It can be readily machined, drilled, turned, and milled to meet specific design requirements. This characteristic enhances the versatility of Spheroidal Graphite Iron and makes it suitable for manufacturing complex parts with tight tolerances.

- Cost-Effectiveness: Spheroidal Graphite Iron offers a cost-effective alternative to materials like steel, especially in applications where a combination of high strength, ductility, and wear resistance is required. It provides comparable or even superior performance at a lower price point, making it an attractive choice for various engineering applications. Additionally, the ability to machine Spheroidal Graphite Iron easily contributes to cost savings in the manufacturing process.

- Damping Properties: Spheroidal Graphite Iron possesses excellent vibration damping properties, which make it ideal for applications where noise and vibration reduction are essential. Its ability to absorb and dissipate vibrations can enhance the overall performance and longevity of machinery and equipment.

These advantages make Spheroidal Graphite Iron a versatile material suitable for a wide range of applications, including automotive components, machinery and equipment, hydraulic systems, pump and valve bodies, engineering structures, and many more. Its unique combination of strength, ductility, wear resistance, and machinability has made it a preferred choice in modern engineering.

1. Enhanced Mechanical Strength and Ductility

Spheroidal graphite iron offers an excellent combination of high tensile strength and ductility, which allows it to withstand significant stress before failure. This combination is particularly beneficial for components that are subject to varying loads and stresses, making ductile iron a preferred material for many structural and mechanical applications.

2. Improved Toughness and Impact Resistance

The nodular graphite inclusions act as crack arresters, significantly enhancing the toughness and impact resistance of the material. This property is crucial for parts used in environments subject to shock loading or impact stresses, such as automotive components, heavy machinery, and infrastructure projects.

3. Good Wear Resistance

Ductile iron exhibits good wear resistance, thanks to its nodular graphite structure and the ability to include various alloying elements in its composition. This makes it suitable for applications with high friction and wear requirements, such as gears, rollers, and pump housings.

4. Excellent Fatigue Resistance

The endurance limit of spheroidal graphite iron is higher than that of many other cast irons and steels, making it ideal for components that experience cyclic loading. This fatigue resistance ensures a longer service life for parts such as crankshafts, connecting rods, and suspension systems.

5. Corrosion Resistance

While not as resistant to corrosion as some coated or alloyed metals, ductile iron offers better corrosion resistance than traditional grey cast iron, especially in environments with less aggressive corrosive agents. This makes it a viable option for pipes and fittings in water and sewage systems, as well as for certain marine applications.

6. Versatility in Engineering Applications

Due to its wide range of beneficial properties, ductile iron is used in a variety of applications across multiple industries. These include automotive parts, water and gas pipelines, agricultural machinery, wind turbine components, and even architectural elements where strength and aesthetic appeal are desired.

7. Cost-Effectiveness

Spheroidal graphite iron provides a cost-effective solution for many engineering applications, considering its mechanical properties and the relative simplicity of its casting process compared to steel fabrication. It allows for the production of complex shapes and sizes without the need for extensive machining or welding, saving both time and manufacturing costs.

8. Recyclability

Like other forms of cast iron and steel, ductile iron is highly recyclable, which contributes to its sustainability as a material choice in engineering projects. The ability to recycle and reuse ductile iron reduces the environmental impact associated with its production and disposal.

In summary, the advantages of spheroidal graphite iron stem from its unique combination of ductility, strength, and toughness, along with its wear and fatigue resistance. These properties make it an indispensable material in modern engineering, offering both performance benefits and cost-effectiveness for a wide range of applications.