Exploring the world of Spheroidal Graphite Cast Iron (SGCI) from a material science perspective provides fascinating insights into why and how this material offers superior properties compared to conventional cast irons. Spheroidal Graphite Cast Iron (SGCI), also known as ductile iron, gets its name from its unique graphite structure, which significantly influences its mechanical and physical properties.

Microstructure

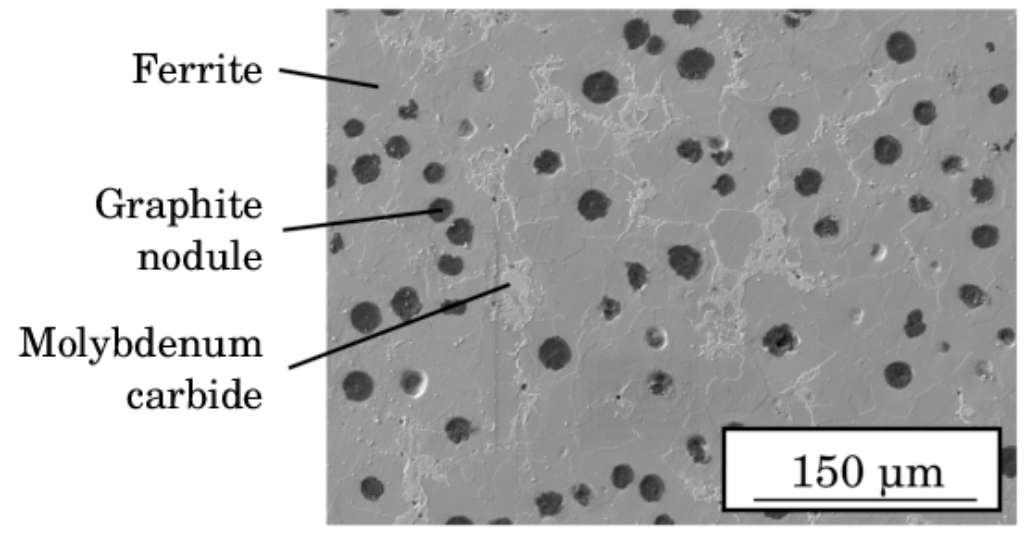

- Graphite Nodules: In Spheroidal Graphite Cast Iron (SGCI), graphite forms in spherical or near-spherical nodules rather than the flake-like shape seen in gray cast iron. This nodule shape is crucial as it minimizes stress concentration points within the iron matrix.

- Matrix Composition: The matrix in Spheroidal Graphite Cast Iron (SGCI) can be ferritic, pearlitic, or a mixture of both, depending on the heat treatment and alloying elements. Ferritic matrices provide better ductility, while pearlitic matrices enhance strength and wear resistance.

Formation and Processing

- Manufacturing Process: The nodular or spheroidal shape of the graphite is achieved by adding magnesium (or sometimes cerium) to the molten iron. This process, known as nodulizing, alters the way carbon crystallizes during solidification.

- Heat Treatment: Post casting, Spheroidal Graphite Cast Iron (SGCI) can undergo various heat treatments like annealing, normalizing, and quenching & tempering to alter its microstructure and achieve desired mechanical properties.

Mechanical Properties

- Strength and Ductility: Spheroidal Graphite Cast Iron (SGCI) exhibits a unique combination of high tensile strength (similar to that of low-carbon steel) and good ductility, attributable to its nodular graphite inclusions.

- Toughness: The spheroidal graphite structure imparts high toughness, making Spheroidal Graphite Cast Iron (SGCI) resistant to impact and fatigue.

- Modulus of Elasticity: Spheroidal Graphite Cast Iron (SGCI) has a lower modulus of elasticity compared to steel, providing better flexibility under load.

Physical Properties

- Density: Typically, Spheroidal Graphite Cast Iron (SGCI) has a density similar to other cast irons, making it heavier than aluminum or plastic composites.

- Thermal Conductivity: The presence of graphite nodules enhances thermal conductivity, beneficial in applications where heat dissipation is crucial.

- Machinability: Due to the graphite inclusions acting as a lubricant, Spheroidal Graphite Cast Iron (SGCI) has superior machinability compared to other ferrous metals.

Applications in Material Science

- Automotive Industry: Spheroidal Graphite Cast Iron (SGCI) is extensively used in manufacturing automotive parts like engine blocks, brake calipers, and gearboxes due to its strength, ductility, and wear resistance.

- Infrastructure: Its use in water and sewage pipes capitalizes on its corrosion resistance and strength.

- Renewable Energy: Components for wind turbines and other renewable energy infrastructure benefit from Spheroidal Graphite Cast Iron (SGCI) mechanical properties and resistance to fatigue.

- Aerospace and Defense: Some applications in aerospace and defense sectors utilize Spheroidal Graphite Cast Iron (SGCI) for its strength-to-weight ratio and machinability.

Future Research and Development

- Alloy Development: Research into alloying Spheroidal Graphite Cast Iron (SGCI) with elements like nickel, chromium, and copper aims to enhance properties like corrosion resistance and strength.

- Tailoring Microstructure: Advanced metallurgical techniques focus on refining the microstructure for specific applications, optimizing the balance between strength, ductility, and toughness.

- Sustainable Manufacturing: Efforts are ongoing to make the production of Spheroidal Graphite Cast Iron (SGCI) more environmentally friendly, reducing energy consumption and emissions.

Spheroidal Graphite Cast Iron stands out in the world of materials science for its unique microstructure that imparts exceptional mechanical and physical properties. Its versatility in applications from heavy industry to precision components showcases its importance and potential for continued innovation in material science.