Sand casting method is usually adopted for machine tool bed, and its process flow mainly includes the following steps:

① Drawing, drawing sand casting drawing of machine tool bed on computer;

② Core making, putting resin sand particles into the mold to form the internal cavity of sand casting;

③ Forming, pouring molten metal liquid in the mold;

④ Open the sand box, remove the molding sand and clean the sand castings;

⑤ Inspect whether sand castings are qualified.

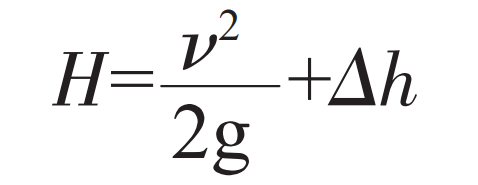

The design basis of sand casting gating system adopts the principle of hydrodynamics. When filling and pouring the cavity below the inner sprue, the pressure head acting on the fluid remains unchanged, and when filling and pouring the cavity above the inner sprue, the pressure head acting on the fluid changes. Assuming that one end of the metal liquid is the metal level of the gate cup and the other end is the outlet of the metal liquid, it is obtained from Bernoulli equation:

Where: H represents the height of sprue; ν Represents the velocity of metal liquid flowing out of the sprue; G represents gravitational acceleration; Δ H is the height of metal liquid head loss.

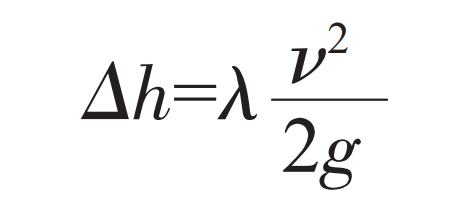

ΔH is expressed by speed head as:

Where: λ Represents the local damping coefficient of the gating system.

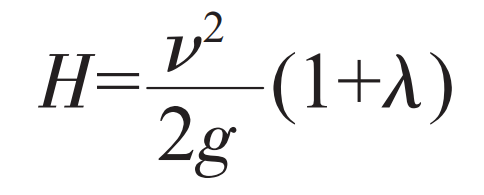

The following formula can be obtained:

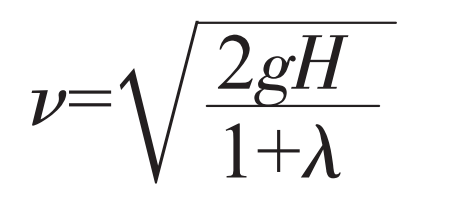

The outlet velocity equation of ingate is:

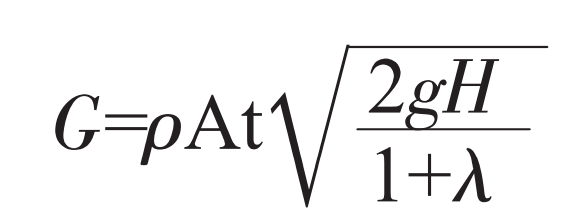

When the metal liquid fills the cavity below the ingate, the weight of the metal liquid through the ingate is calculated as follows:

Where: G represents the weight of metal liquid flowing in the cavity below the ingate; ρ Represents the density of the metal liquid; A represents the cross-sectional area of the sprue pipe; T is the time to fill the lower cavity.