1. Structure description of sand casting coupling parts

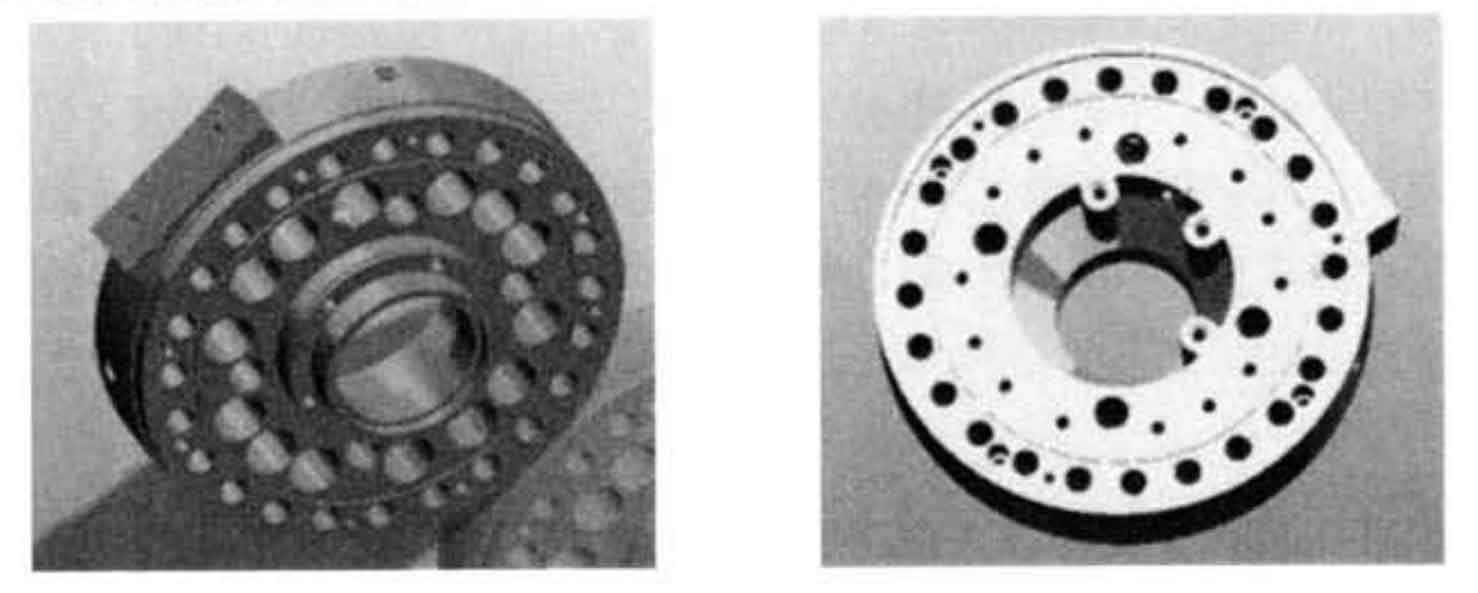

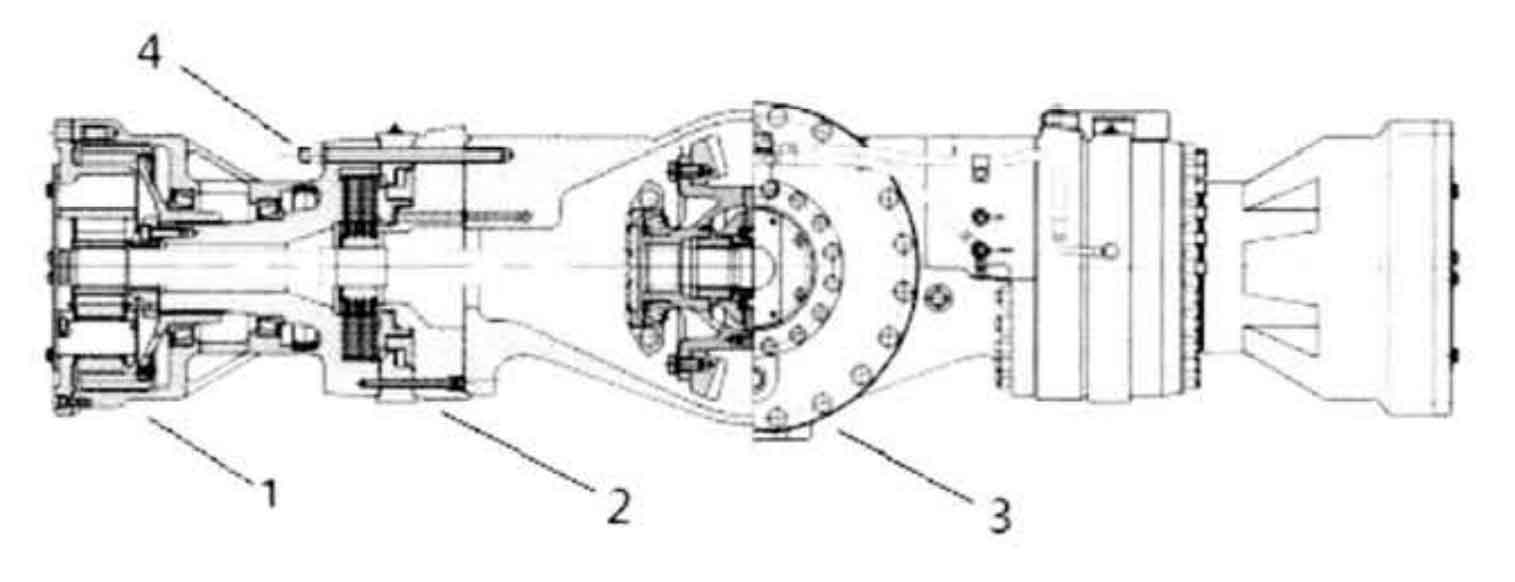

Based on the above reasons, this topic adds the working condition mechanical property analysis of parts to the sand casting process design, and puts this part before the specific sand casting process design, hoping to analyze the weak areas of parts, and take this as a reference for sand casting process design. The parts shown in Figure 1 are the rendered finished parts structure diagram of the cast parts of a certain type of shell coupling of caterpillar, a large multinational construction machinery enterprise. Figure 2 shows the split drive axle of a heavy truck containing this part. Axle housings 1 and 3 are combined together through sand casting coupling 2 and bolt 4. This drive axle structure is convenient for disassembly and maintenance.

2. Introduction to working conditions of sand casting coupling parts

Main parameters of the split drive axle:

Rated static load: g = 13T

Track width: w = 1960mm

Spring distance: l = 950mm

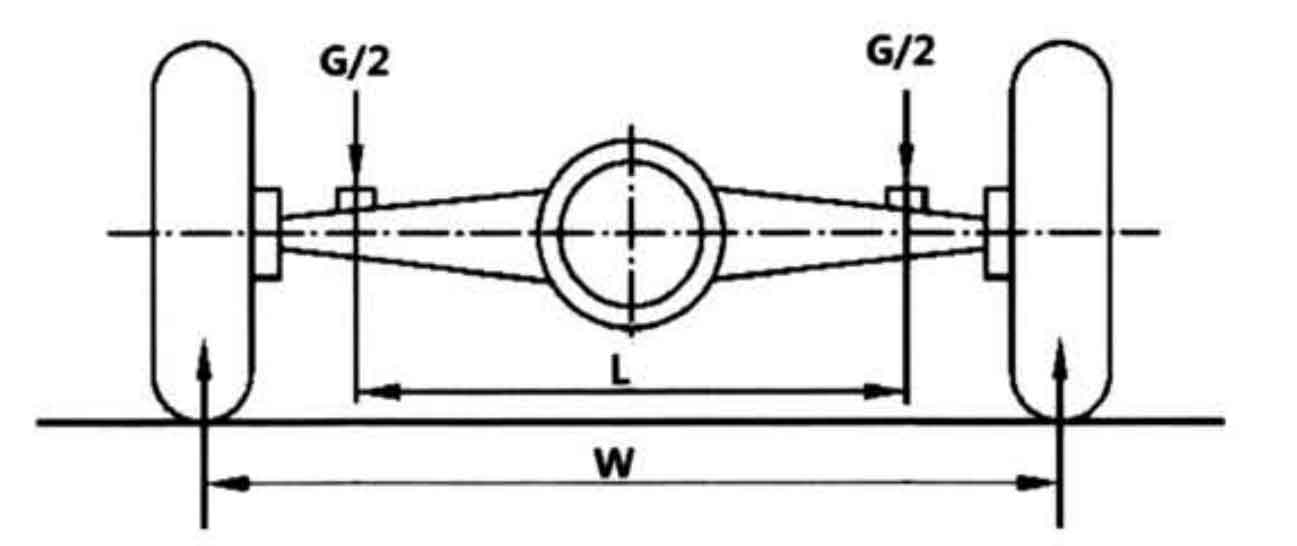

There are three typical calculation conditions of the drive axle: vertical force load condition (full load driving, only bearing vertical impact load condition), tangential force load condition (full load braking or maximum traction force condition), lateral force load condition (full load sideslip or rollover condition). Generally, dangerous working conditions occur in vertical force loading conditions. Therefore, this working condition is used to check the strength of sand casting coupling parts in this paper. The stress diagram of vertical force load condition is shown in Figure 3. The full load vertical force load is borne by two leaf spring supports.

In order to improve the calculation accuracy, the radial stiffness of the tire needs to be considered in the calculation. The calculation formula of radial stiffness of driving wheel is:

Where:

K – radial stiffness of driving wheel (KN);

P — tire pressure (kPa);

Take the tire pressure P of heavy vehicle as P = 800kpa and bring it into the above formula to obtain the radial stiffness of the driving wheel as:

3. Finite element analysis of sand casting coupling parts

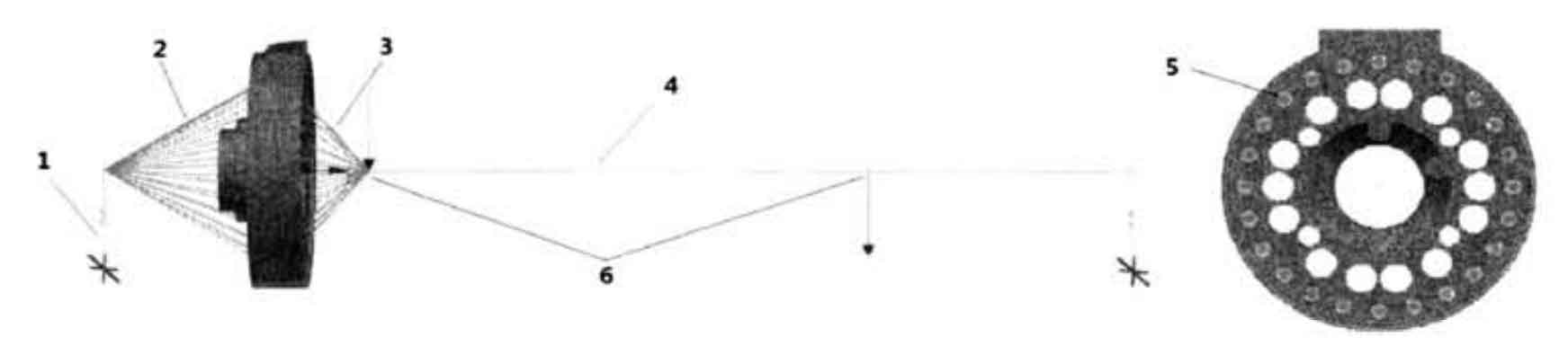

The simplified finite element model of the drive axle is shown in Figure 4, where l is the spring element, which is used to simulate the tire, and its stiffness coefficient is equal to the radial stiffness of the drive wheel: 2 and 3 are rbe3 elements, which are used to simulate the connection between the drive axle housing and coupling parts, 4 are beam elements, which are used to simulate the drive axle housing, 5 are rbe2 elements, which are rigid elements, which are used to simulate bolt connection. Under full load condition, the dynamic load coefficient is 2.5. Therefore, the load under full load condition g = GX2 5=13 × 2.5 = 32.5t, applied to the node 6 corresponding to the two leaf spring supports, and all degrees of freedom of the two spring units 1 are fixed at the same time.

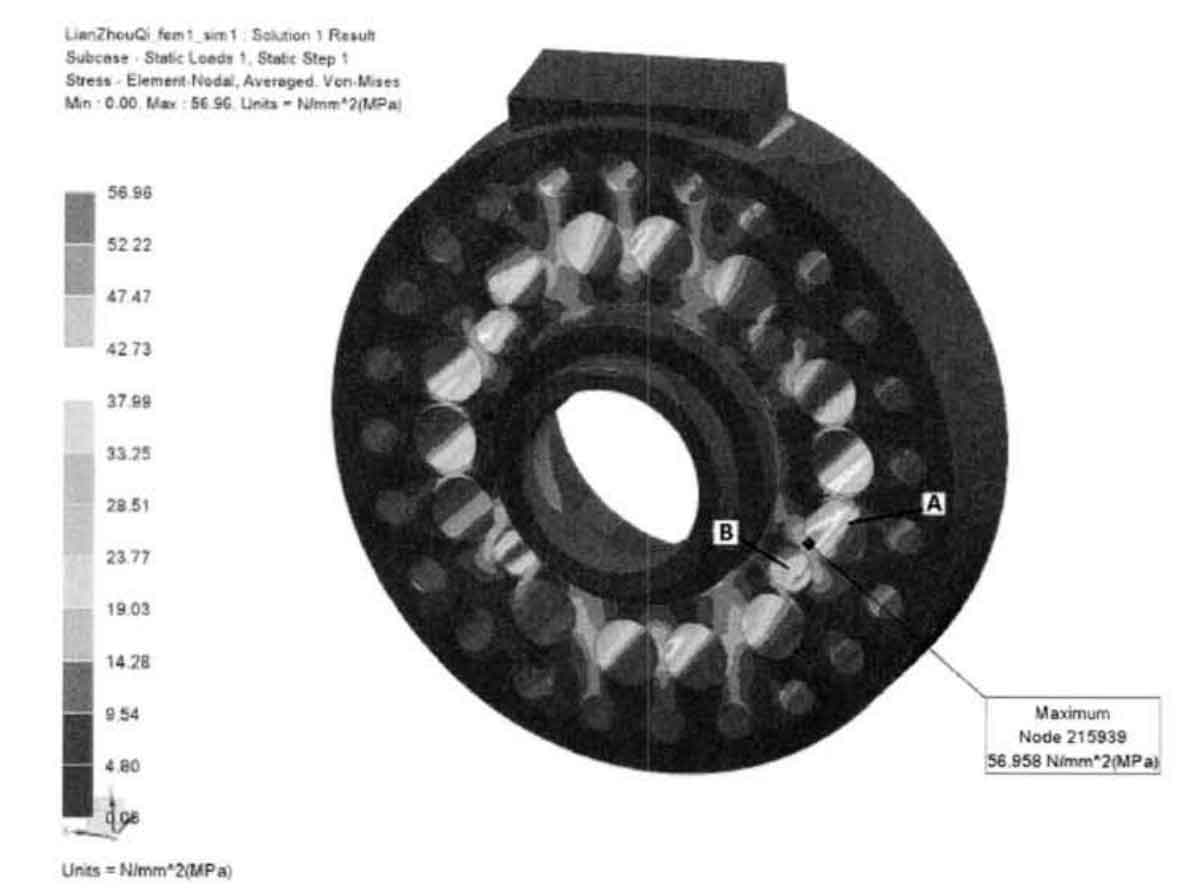

The stress nephogram of sand casting coupling parts is shown in Figure 5, and the maximum stress is 56.96mpa, meeting the allowable stress requirements; The maximum stress is located in the connection area between hole a and hole B. the wall thickness of the connection area is thin and the stress is high. Except for several hole structures close to each other, the stress on the periphery of sand casting coupling parts is obviously low. Therefore, when designing the sand casting process, we should focus on ensuring the pouring quality of the part between the holes and try to make the part solidify as early as possible. When designing the feeding system, we should also keep the specific feeding measures away from the part to ensure the material performance after the local liquid metal crystallization molding. Therefore, the specific feeding and exhaust measures should be designed in the peripheral area of the coupling parts of sand casting as far as possible.