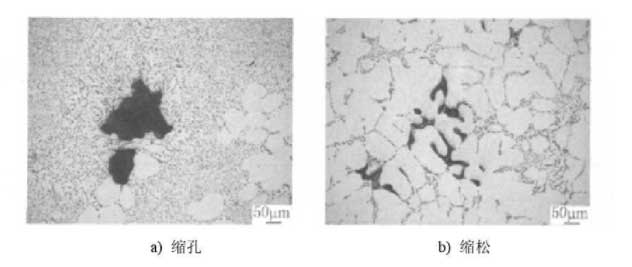

Shrinkage cavity and porosity are inevitable defects in a kind of die casting wheel. In the microstructure, the shrinkage cavity is irregular, unsmooth, large and concentrated, while the shrinkage cavity is small and scattered, which results in poor mechanical properties of wheels to some extent. The shrinkage and porosity defects under the optical microscope are shown in the figure.

In the solidification process of alloy liquid from liquid phase to solid phase, there will be volume shrinkage. In the area where the solidification process is not well supplemented by liquid alloy liquid, there will be shrinkage cavity or shrinkage casting defect in the area where the liquid alloy liquid is supplemented [30-32]. [30-32]. There are three kinds of shrinkage in the process of solidification: liquid shrinkage, solidification period shrinkage and solid shrinkage. The so-called liquid volume shrinkage refers to the shrinkage when the alloy liquid temperature is above the liquid phase temperature; the shrinkage when the liquid-solid phase coexists is the second form of shrinkage; and the solid volume, as the name implies, refers to the volume reduction when the solid phase cools to the normal temperature, and the solidification shrinkage of A356 material is about 6 ‰. The filling process of aluminum alloy wheel low-pressure casting is shown in the figure:

The arrow in the figure indicates the flow direction of liquid metal. The riser acts as the gate in the center of the wheel. The aluminum liquid flows through the transverse sprue of the spoke to the rim and the rim. The hot spot often appears at the root of the spoke. However, the temperature of molten metal in the hub and spoke is high, and the wall thickness is thick. If the shrinkage is not good in the solidification process, the defects such as holes will appear. The wheel center is cooled by water cooling, while the other parts are cooled by air duct. The final solidification part is easy to have shrinkage porosity, shrinkage cavity and other defects due to insufficient feeding. According to the practical production experience, the root, spoke, rim and center of the wheel are all the parts that are easy to appear.

The picture of shrinkage porosity is as shown in the figure. The formation of series of shrinkage porosity in the figure is due to the breaking of the directional sequential solidification of aluminum alloy liquid, and the solid phase surrounding a small part of the liquid phase, so that the surrounded area can not get enough supplement of aluminum alloy liquid.