Chapter 1: The Basic Principles of Gravity Casting

Gravity casting, also known as permanent mold casting, is a metal casting process that uses the force of gravity to fill molds with molten metal. It is commonly used for producing parts with good dimensional accuracy and surface finish. Here’s a detailed overview of the basic principles and process flow of gravity casting:

Process Principles: Gravity casting relies on the force of gravity to fill a reusable mold with molten metal. The molten metal is poured into the mold, where it solidifies and takes the shape of the mold cavity. The process is suitable for a wide range of metals, including aluminum, copper, and magnesium alloys.

Process Flow:

- Mold Design and Manufacturing:

- A reusable mold, typically made of metal (cast iron, steel), is designed to create the desired part shape.

- The mold consists of two halves: the stationary “cover” and the “core,” which can be removed to release the casting.

- Mold Preparation:

- The mold surfaces are cleaned and coated with a release agent to facilitate part removal and prevent sticking.

- Metal Liquid Preparation:

- The metal alloy is melted in a furnace, maintaining precise temperature control.

- Alloys may be alloyed, degassed, and fluxed to improve casting quality.

- Casting Operation:

- The molten metal is poured into the mold through a pouring basin or sprue.

- Gravity ensures the metal flows through the mold cavity, filling it completely.

- Solidification and Cooling:

- As the metal fills the mold, it begins to solidify. The metal’s temperature and alloy composition determine its solidification behavior.

- Heat is dissipated through the mold walls, causing the metal to solidify gradually.

- Mold Unloading and Part Removal:

- After solidification is complete, the mold is opened, and the casting is removed.

- The casting is typically attached to the sprue and gating system, which is trimmed or machined off to achieve the final shape.

Advantages of Gravity Casting:

- Good dimensional accuracy and surface finish.

- Suitable for a wide range of metals.

- Reusable molds offer cost savings for larger production runs.

- Minimal turbulence during pouring reduces the risk of gas porosity.

Limitations and Considerations:

- Limited to relatively simple part geometries due to mold design constraints.

- Solidification rates can affect microstructure and mechanical properties.

- Tooling and mold maintenance are crucial for maintaining consistent quality.

Gravity casting is a versatile process that strikes a balance between the complexity of sand casting and the precision of die casting. Its ability to produce parts with high accuracy and a relatively smooth finish makes it a preferred choice for various industries, especially for producing medium to large-sized components in aluminum and other alloys.

Chapter 2: The Equipment and Facilities for Gravity Casting

Gravity casting requires specific equipment and facilities to successfully carry out the casting process. Here’s an overview of the key equipment and facilities involved in gravity casting, along with their types, characteristics, operating methods, and maintenance considerations:

1. Casting Machines:

- Types: There are different types of gravity casting machines, including tilt pour machines, static pour machines, and low-pressure casting machines.

- Characteristics: These machines facilitate controlled pouring of molten metal into the molds under the force of gravity. Tilt pour machines tilt the mold to control filling, while static pour machines rely on precise pouring techniques.

- Operating Method: Operators load the mold onto the machine, and molten metal is poured into the mold. The machine may have features for controlling pouring speed and angle.

2. Liquid Metal Processing Systems:

- Types: Crucible furnaces, electric resistance furnaces, and induction furnaces are commonly used for melting and holding the molten metal.

- Characteristics: These systems provide controlled heating and melting of metal alloys, ensuring proper temperature and composition.

- Operating Method: The metal is loaded into the furnace, where it is heated to the required temperature. Molten metal is then transferred to the pouring system.

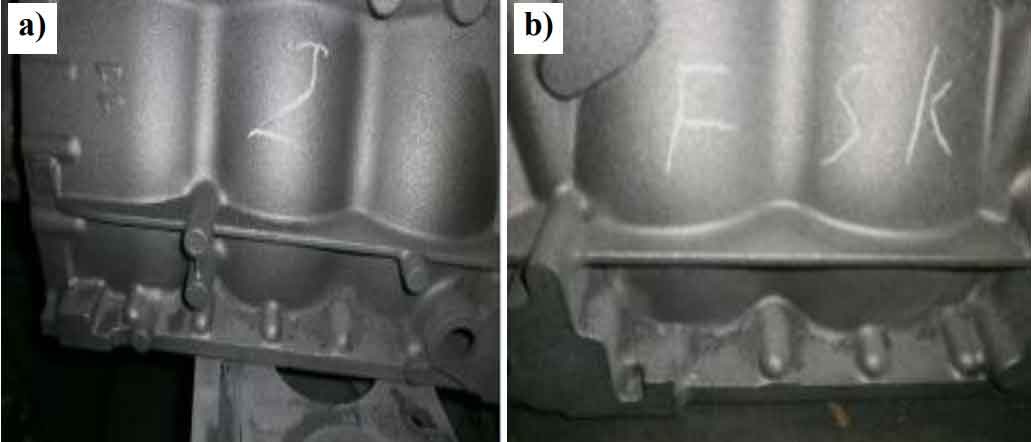

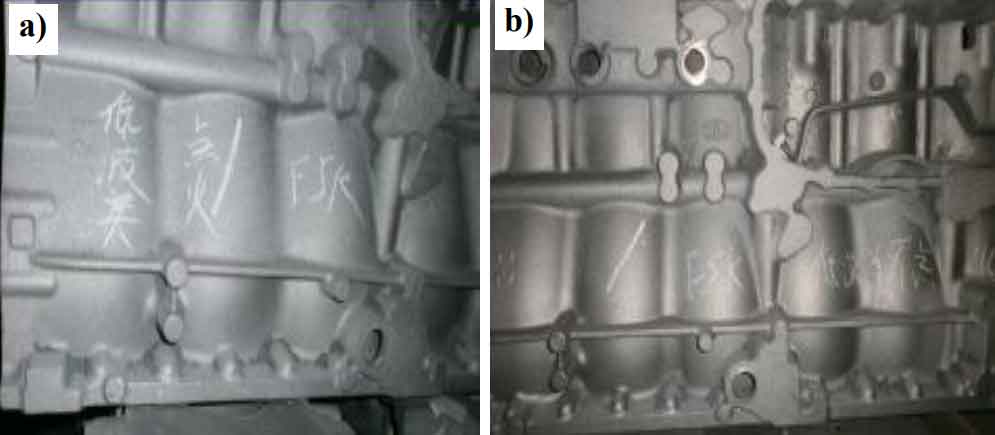

3. Molds:

- Types: Permanent molds, typically made from cast iron or steel, are used for gravity casting. Mold design may vary based on part geometry.

- Characteristics: Permanent molds are reusable and designed to withstand repeated casting cycles. They need to be carefully maintained to ensure consistent quality.

- Operating Method: Molds are preheated and prepared with a release agent. Molten metal is poured into the mold, and after solidification, the mold is opened to remove the casting.

4. Cooling Systems:

- Characteristics: Cooling systems are crucial for controlling the solidification rate and preventing defects. Water-based cooling systems may involve channels or cooling jackets around the mold.

- Operating Method: Cooling systems are activated during casting and maintained to control the cooling rate and ensure proper solidification.

Equipment Selection and Maintenance:

- Selection Criteria:

- Choose equipment that suits your production volume, part complexity, and material requirements.

- Consider factors such as pouring control, heating capacity, and cooling efficiency.

- Maintenance:

- Regularly inspect and clean casting machines to ensure proper functioning and avoid metal contamination.

- Maintain furnaces by periodically checking heating elements, thermocouples, and crucibles.

- Monitor and clean cooling systems to prevent clogs and ensure effective heat dissipation.

- Keep molds in good condition through proper cleaning, coating, and repairing any wear or damage.

- Training:

- Properly train operators to handle the equipment, follow safety protocols, and troubleshoot issues.

- Regularly update the team on maintenance procedures and best practices.

- Quality Control:

- Implement quality control measures to monitor the performance of equipment and ensure consistent casting quality.

- Regularly inspect castings for defects and assess the condition of molds and equipment.

By carefully selecting, operating, and maintaining gravity casting equipment and facilities, you can ensure efficient and high-quality production while minimizing downtime and defects.

Chapter 3: Metal Materials Suitable for Gravity Casting

Gravity casting is compatible with various metal materials, each with its own set of characteristics and performance during the casting process. Here’s an overview of some common metal materials suitable for gravity casting, along with their performance and application considerations:

1. Aluminum Alloys:

- Characteristics: Aluminum alloys are widely used in gravity casting due to their good casting properties, low density, corrosion resistance, and excellent thermal conductivity.

- Performance During Casting: Aluminum alloys exhibit relatively low shrinkage and excellent fluidity during casting. They solidify quickly, which can aid in achieving fine surface finishes.

- Pre-treatment: Prior to casting, aluminum alloys may undergo degassing to remove gases that can cause porosity. Grain refinement may also be performed to improve mechanical properties.

- Application Range: Aluminum gravity casting is commonly used in automotive components, aerospace parts, and a variety of consumer and industrial products.

2. Magnesium Alloys:

- Characteristics: Magnesium alloys are lightweight and offer good strength-to-weight ratios, making them attractive for applications requiring lightweight structures.

- Performance During Casting: Magnesium alloys have good fluidity and low melt viscosity, facilitating smooth filling of molds. Proper temperature control is essential to avoid oxide formation.

- Pre-treatment: Magnesium alloys are prone to oxidation, so proper melting and handling procedures are crucial. Protective atmospheres or fluxes may be used to prevent oxidation.

- Application Range: Magnesium gravity casting finds use in aerospace, automotive, and electronics industries where weight reduction is important.

3. Copper Alloys:

- Characteristics: Copper alloys are valued for their high thermal and electrical conductivity, as well as their corrosion resistance.

- Performance During Casting: Copper alloys require higher pouring temperatures due to their higher melting points. They can exhibit lower fluidity compared to aluminum or magnesium alloys.

- Pre-treatment: Copper alloys may require fluxes or protective atmospheres to minimize oxidation during melting and pouring.

- Application Range: Copper gravity casting is often used for electrical components, plumbing fittings, and decorative items.

4. Zinc Alloys:

- Characteristics: Zinc alloys offer good casting properties, high fluidity, and excellent dimensional stability.

- Performance During Casting: Zinc alloys have relatively low melting points, allowing for easy casting. They can provide intricate detailing and good surface finishes.

- Pre-treatment: Zinc alloys are less prone to oxidation, but careful temperature control and proper melting procedures are still important.

- Application Range: Zinc gravity casting is employed for various consumer goods, electronics, and decorative items.

Material Selection Considerations:

- Mechanical Properties: Choose materials that meet the required strength, hardness, and other mechanical properties for the intended application.

- Corrosion Resistance: Consider the environment in which the casting will be used and select materials with suitable corrosion resistance.

- Weight Requirements: Choose materials based on weight considerations, especially for applications where lightweighting is important.

- Surface Finish: Different materials may result in different surface finishes, affecting the casting’s appearance and functionality.

In all cases, proper handling, pre-treatment, and temperature control during the melting and casting processes are essential to achieve high-quality castings with the desired properties.

Chapter 4: The Quality Control in Gravity Casting Process

Quality control in the gravity casting process is crucial to ensure that castings meet the required specifications for size, shape, and surface quality. Various testing methods are employed to detect and control these parameters. Here’s an overview of commonly used quality control methods in gravity casting:

1. Visual Inspection:

- Description: Visual inspection is the most basic quality control method. It involves visually examining castings for surface defects, dimensional discrepancies, and other visible irregularities.

- Application: Visual inspection is used throughout the casting process, from mold preparation and pouring to post-casting processes.

2. Dimensional Inspection:

- Description: Dimensional inspection involves measuring the dimensions of castings using precision tools such as calipers, micrometers, and coordinate measuring machines (CMMs).

- Application: Dimensional inspection ensures that castings meet specified size and shape requirements.

3. X-ray Testing (Radiographic Inspection):

- Description: X-ray testing uses X-rays to inspect the interior of castings for defects such as porosity, shrinkage, and inclusions. It is particularly effective for detecting internal defects.

- Application: X-ray testing is used to ensure the integrity of critical components where internal defects could compromise structural integrity.

4. Ultrasonic Testing:

- Description: Ultrasonic testing uses high-frequency sound waves to detect internal defects by analyzing the reflections of the waves.

- Application: Ultrasonic testing is used to identify defects such as voids, inclusions, and cracks in castings.

5. Magnetic Particle Testing:

- Description: Magnetic particle testing uses magnetic fields and magnetic particles to identify surface and near-surface defects.

- Application: This method is effective for detecting defects like cracks, laps, and seams on the surface of castings.

6. Dye Penetrant Testing:

- Description: Dye penetrant testing involves applying a liquid dye to the surface of a casting, allowing it to seep into surface cracks and defects. Excess dye is removed, and a developer is applied to reveal the defects.

- Application: Dye penetrant testing is used to detect surface cracks, porosity, and other surface defects.

7. Pressure Testing:

- Description: Pressure testing involves subjecting castings to pressurized fluids or gases to detect leaks and assess the integrity of the casting.

- Application: Pressure testing is used to ensure the sealing integrity of castings, particularly for components that need to hold fluids or gases.

8. Hardness Testing:

- Description: Hardness testing measures the hardness of a casting’s surface using methods like Brinell, Rockwell, or Vickers hardness tests.

- Application: Hardness testing provides insight into the mechanical properties and structural integrity of the casting.

9. Microstructural Analysis:

- Description: Microstructural analysis involves examining the metal’s microstructure under a microscope to assess grain size, distribution, and other characteristics.

- Application: Microstructural analysis helps determine material quality, heat treatment effects, and potential defects.

Each of these quality control methods serves a specific purpose and helps ensure that gravity castings meet the desired standards for size, shape, and surface quality. Combining these methods allows manufacturers to identify and address defects and irregularities at various stages of the casting process.

Chapter 5: The Application Field of Gravity Casting in Industrial Production

Gravity casting finds application in various industrial fields due to its versatility and ability to produce high-quality components. Here’s an overview of gravity casting’s application fields and the specific requirements for casting performance and quality in each field, along with optimization strategies:

1. Aerospace:

- Application: Gravity casting is used in aerospace for manufacturing engine components, structural parts, and other critical components.

- Requirements: Aerospace components demand high precision, mechanical strength, and resistance to high temperatures and stress.

- Optimization: Use advanced alloys with specific properties for aerospace applications. Implement precision mold design and stringent quality control to ensure dimensional accuracy and integrity.

2. Automotive Manufacturing:

- Application: Gravity casting is widely used in automotive manufacturing for engine blocks, cylinder heads, transmission components, and structural parts.

- Requirements: Automotive castings need to meet strict dimensional tolerances, high mechanical properties, and excellent surface finish.

- Optimization: Employ optimized gating and riser systems to control solidification and minimize defects. Implement advanced simulation tools for mold filling and solidification analysis.

3. Energy Industry:

- Application: Gravity casting is utilized in the energy sector for producing components such as turbine blades, housings, and heat exchanger parts.

- Requirements: Energy industry components require high-temperature resistance, corrosion resistance, and superior mechanical properties.

- Optimization: Select appropriate high-temperature alloys and ensure precise temperature control during casting. Use proper cooling systems to achieve the desired microstructure.

4. Electrical Industry:

- Application: Gravity casting is used in the electrical industry for producing housings, enclosures, and components for electrical equipment.

- Requirements: Electrical castings must have good electrical conductivity, thermal conductivity, and resistance to environmental factors.

- Optimization: Opt for suitable copper-based or aluminum alloys with the desired electrical properties. Ensure proper material handling and melt control.

5. Consumer Goods:

- Application: Gravity casting is employed for producing various consumer goods such as cookware, lighting fixtures, and decorative items.

- Requirements: Consumer goods require aesthetic appeal, precise dimensions, and surface finish.

- Optimization: Pay attention to mold design, coating, and surface finishing techniques to achieve desired aesthetics. Implement proper quality control to maintain consistent appearance.

6. Industrial Machinery:

- Application: Gravity casting is used in industrial machinery for producing components like gears, pulleys, brackets, and pump housings.

- Requirements: Industrial machinery castings must exhibit good mechanical properties, dimensional accuracy, and wear resistance.

- Optimization: Select appropriate alloys for wear resistance. Implement precision mold design and cooling strategies to control microstructure and mechanical properties.

7. Medical Equipment:

- Application: Gravity casting is employed in medical equipment for producing components like instrument housings and structural parts.

- Requirements: Medical equipment requires biocompatibility, precision, and smooth, defect-free surfaces.

- Optimization: Choose biocompatible alloys and ensure stringent surface finish requirements are met. Implement thorough quality control to ensure the absence of defects.

In each application field, the optimization of gravity casting processes involves selecting suitable alloys, designing molds to meet specific requirements, controlling solidification rates, and implementing effective quality control measures. Collaboration between casting engineers, metallurgists, and design teams is crucial to tailor the casting process to meet the unique demands of each industry.

Chapter 6: The Development Trend and Innovation Direction of Gravity Casting Technology

Gravity casting technology is continuously evolving to meet the demands of various industries and to take advantage of advancements in materials, processes, automation, and digital technology. Here are some development trends and innovative directions in gravity casting technology:

1. Advanced Materials:

- Development: The use of advanced materials, including high-performance alloys and composites, is gaining traction. These materials offer improved mechanical properties, corrosion resistance, and thermal characteristics.

- Impact: Advanced materials allow for the production of castings with enhanced performance and functionality, making them suitable for demanding applications in aerospace, automotive, energy, and more.

2. Process Improvement:

- Development: Continuous process improvement focuses on optimizing gating and riser systems, reducing defects, and enhancing casting quality and consistency.

- Impact: Improved process control leads to higher yields, reduced scrap rates, and enhanced casting properties, ultimately improving the overall efficiency and cost-effectiveness of gravity casting.

3. Automation and Robotics:

- Development: Automation and robotics are being integrated into gravity casting processes for tasks such as mold handling, pouring, and post-casting operations.

- Impact: Automation enhances consistency, reduces labor costs, and increases throughput. It also improves worker safety by minimizing exposure to hazardous tasks.

4. Digital Technology and Simulation:

- Development: Simulation tools are increasingly used for mold filling, solidification analysis, and predicting casting defects. Digital twinning and virtual reality are also being employed to optimize casting processes.

- Impact: Digital technology allows for more accurate and efficient process design, reducing the need for trial and error. It enables engineers to identify and address potential issues before physical casting.

5. Additive Manufacturing and Hybrid Processes:

- Development: Additive manufacturing, or 3D printing, is being explored for creating molds, cores, and patterns used in gravity casting. Hybrid processes that combine traditional casting with additive manufacturing are also emerging.

- Impact: Additive manufacturing offers design flexibility, faster prototyping, and reduced lead times for tooling. Hybrid processes can improve efficiency and create complex shapes more easily.

6. Sustainable Practices:

- Development: Sustainability considerations are driving the adoption of greener practices, such as using eco-friendly binders and reclaiming and recycling sand.

- Impact: Sustainable practices reduce environmental impact and resource consumption, aligning with global environmental goals.

7. Real-time Monitoring and Data Analytics:

- Development: Real-time monitoring and data analytics are used to track process variables, predict defects, and optimize casting parameters.

- Impact: Data-driven decision-making improves quality control, reduces waste, and enhances overall process efficiency.

8. Customization and Small-Batch Production:

- Development: The ability to efficiently produce small batches of customized components is becoming increasingly important in various industries.

- Impact: Flexible gravity casting processes can cater to the growing demand for customization, enabling rapid prototyping and efficient production of low-volume, high-value parts.

Gravity casting technology is poised to embrace these trends and innovations, leading to more efficient, sustainable, and high-quality casting processes that meet the diverse needs of modern industries.

Chapter 7: The Impact and Response Measures of Gravity Casting in Environmental Protection and Sustainability.

Gravity casting, like any manufacturing process, has an impact on the environment, including energy consumption, waste generation, and resource utilization. However, there are several measures that can be taken to minimize the environmental impact and promote sustainability in gravity casting:

1. Waste Reduction:

- Recycling: Implement sand reclamation systems to recycle and reuse sand, reducing the need for new sand and minimizing waste.

- Refractory Materials: Opt for longer-lasting refractory materials for molds and cores to reduce the frequency of replacements and waste.

- Waste Management: Properly manage and dispose of waste materials, such as used sand, binders, and other casting-related byproducts, following environmental regulations.

2. Energy Efficiency:

- Furnace Efficiency: Use energy-efficient furnaces and heating technologies to minimize energy consumption during the melting process.

- Heat Recovery: Implement heat recovery systems to capture and reuse heat generated during the casting process for other purposes.

3. Resource Optimization:

- Material Selection: Choose materials that have lower environmental impacts and can be easily recycled or reused.

- Lean Manufacturing: Implement lean manufacturing principles to optimize resource usage and reduce material waste.

4. Green Binders and Coatings:

- Use of Eco-friendly Binders: Explore the use of eco-friendly binders and coatings that have lower environmental impact and are easier to reclaim or recycle.

5. Process Innovation:

- Optimized Casting Parameters: Use simulation tools to optimize casting parameters, reducing the need for trial and error and minimizing waste.

- Automation: Implement automated processes and robotics to improve process control, reduce variability, and enhance efficiency.

6. Environmental Compliance and Certification:

- Regulatory Compliance: Adhere to environmental regulations and standards to minimize negative environmental impacts.

- Certification: Obtain environmental certifications that demonstrate your commitment to sustainable practices.

7. Education and Training:

- Employee Awareness: Train employees on sustainable practices and the importance of environmental protection.

- Continuous Improvement: Encourage a culture of continuous improvement by involving employees in identifying and implementing sustainable initiatives.

8. Life Cycle Assessment:

- Assess Environmental Impact: Conduct a life cycle assessment to analyze the overall environmental impact of the casting process and identify areas for improvement.

9. Collaboration and Innovation:

- Supplier Engagement: Collaborate with suppliers to source eco-friendly materials and technologies that align with sustainability goals.

- Research and Development: Invest in research and development to explore innovative materials, processes, and technologies that have reduced environmental impact.

By implementing these measures, gravity casting operations can reduce waste generation, save energy, optimize resource utilization, and contribute to environmental protection and sustainability goals. It’s essential to continually assess and improve practices to minimize the ecological footprint of the casting process.