The solidification process of castings includes phase change, heat and mass transfer, and the heat transfer phenomenon is in the dominant position. From pouring to solidification, the heat transfer of molten metal runs through the whole process in different ways. Solidification simulation is to establish and solve the equation of solidification heat transfer problem. By solving the heat transfer equation of solidification process, the change law of temperature field in solidification process can be obtained. On this basis, the microstructure and performance characteristics can be inferred.

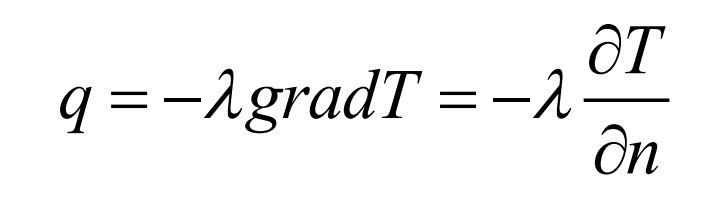

(1) Heat conduction: heat conduction is referred to as heat conduction for short. Under the condition of relative displacement, each part of the object only relies on the thermal movement of the microscopic example of the material to transfer heat from the high-temperature part to the low-temperature part. Heat conduction belongs to contact heat transfer. In the solidification process, the metal liquid mainly transfers heat to the coating layer and molding sand in the form of unstable heat conduction. In the heat conduction process of unstable heat conduction, the heat flow Q value is directly proportional to the negative value of temperature gradient:

Where q is the heat transfer (conductivity) density, λ Represents thermal conductivity, and T represents temperature (k or ℃).

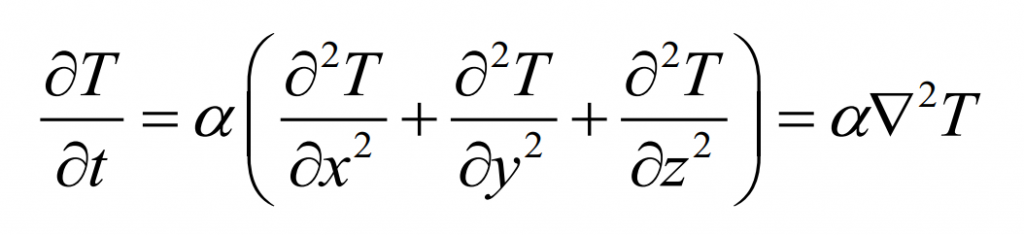

Fourier heat conduction differential equation is the basic operation method of unstable heat conduction:

Where △ is the Laplace operator, α Is the thermal diffusion factor.

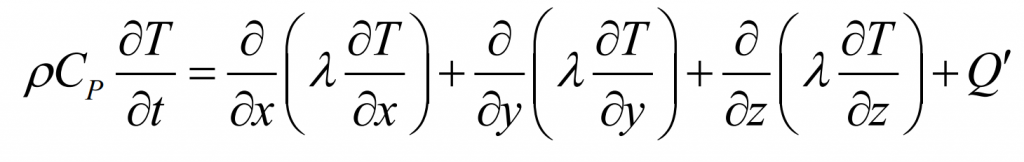

The latent heat of crystallization will also be released during solidification and crystallization. This heat change caused by phase transformation can be solved as a temperature field with internal heat source. The heat conduction equation considering internal heat source is:

Where Q ‘is the latent heat of solidification (J / kg).

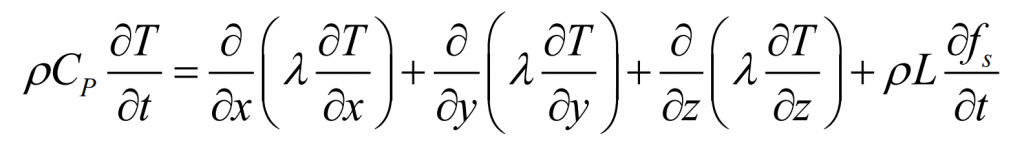

The Fourier equation considering the latent heat of crystallization can be derived from the above formula:

Where l is the latent heat of crystallization (J / kg) and FS is the solid rate. When solving the equation, the equivalent specific heat capacity method, temperature rise method and enthalpy method are generally used to analyze the crystallization latent heat.

(2) Thermal convection: also known as convective heat transfer, it refers to the phenomenon of heat exchange caused by the flow between various parts of fluid with temperature difference. This phenomenon exists between high-temperature liquid metal and dry sand mold and between sand mold and the outside world in the solidification process of lost foam casting, The mathematical model for dealing with convective heat transfer is the basic method for dealing with the mathematical model of convective heat transfer according to Newton’s cooling law:

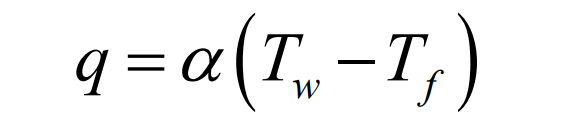

Newton’s cooling law:

Where q is the convective heat transfer density, α Is the interface heat transfer coefficient, TW is the boundary temperature of metal flow (k), and TF is the interface boundary temperature of dry sand mold.

(3) Heat radiation: the numerical model treatment method of heat radiation in lost foam casting process is Stefen boltsman’s Law:

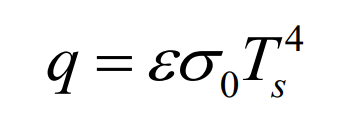

Stefen boltsman’s Law:

Where q is the heat radiation density, ε Blackness of material, ε= Q / Q0, Q0 is the radiation force of absolute blackbody; σ 0 is Stefen boltsman constant and TS is surface temperature (k).