1. Improve the stiffness and strength of lost foam casting sand box

The bottom of lost foam casting sand box is reinforced with #10 channel steel. On the one hand, the stiffness is increased; On the other hand, the lost foam casting sand box is connected into an integral frame, which is conducive to the transmission of vibration force. The specific improvement scheme is shown in Figure 1. The improved lost foam casting sand box can eliminate the problems of desoldering of the support column and deformation of the bottom plate of the existing sand box.

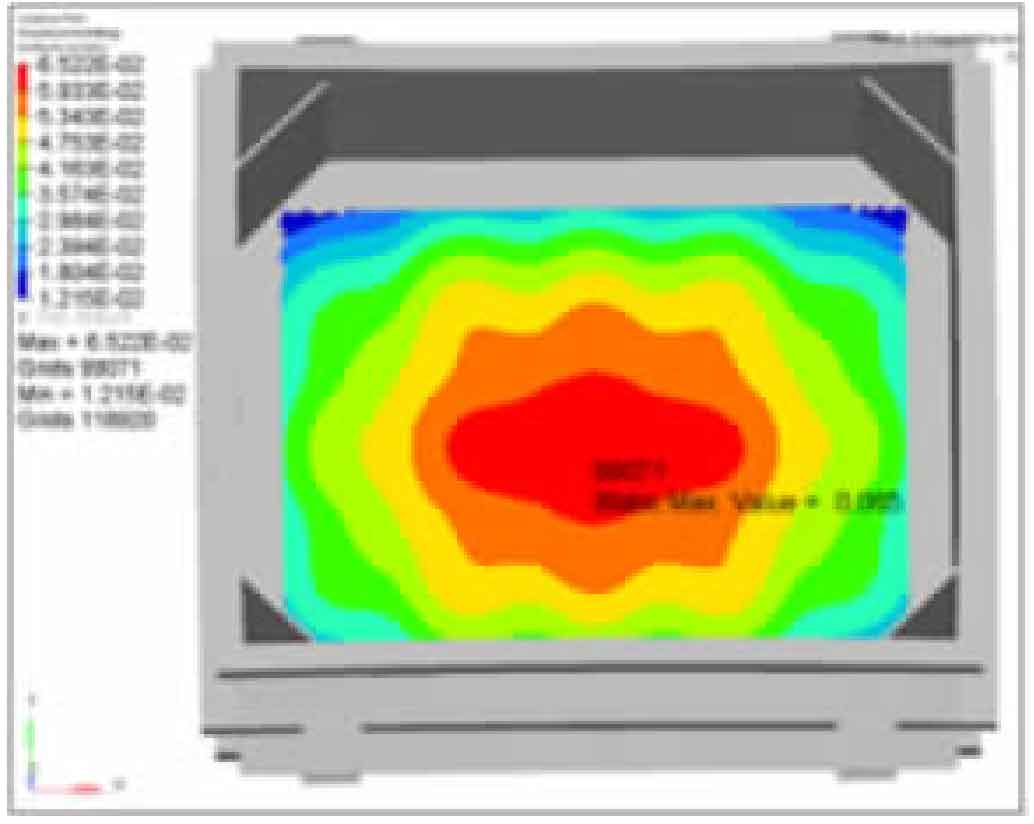

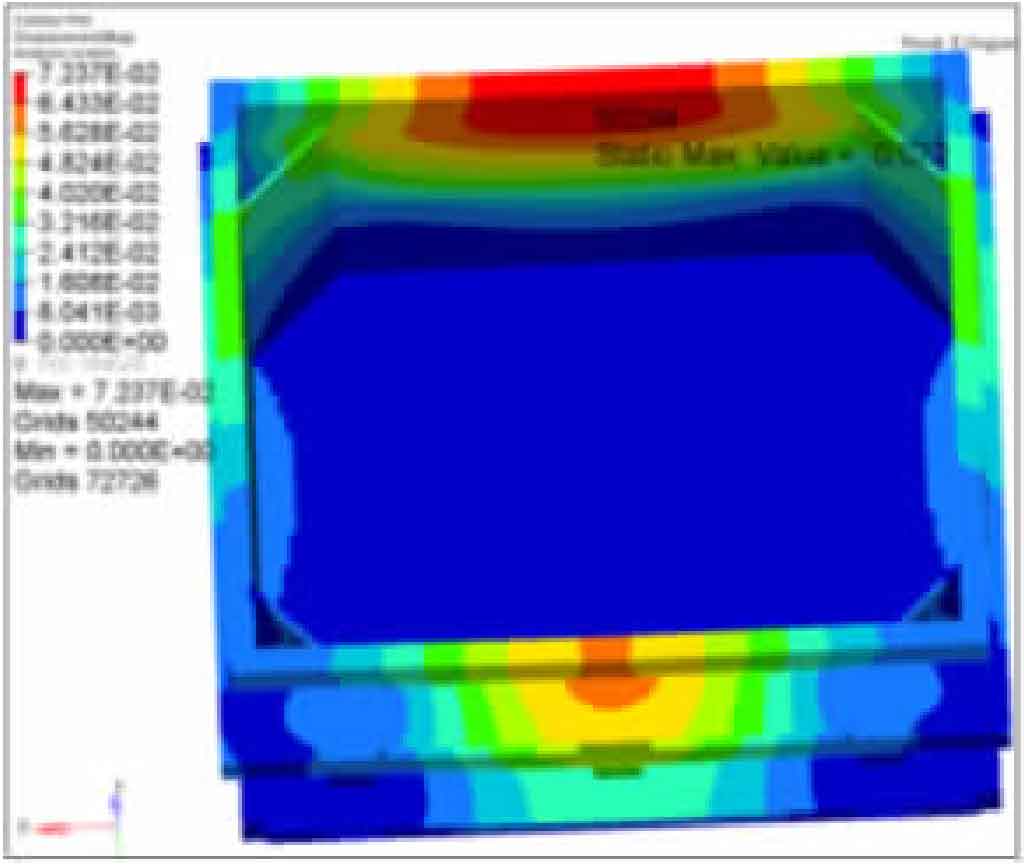

The deformation of sand box is calculated by mechanical simulation software to ensure the improvement effect. Figure 2 shows the deformation analysis of the bottom and side of lost foam casting sand box. It can be seen that the deformation is 1 / 3 of the original structural scheme, indicating that the improved scheme is feasible, which can improve the stiffness and reduce the deformation of lost foam casting sand box.

2. Structure and control of lost foam casting vibrating system

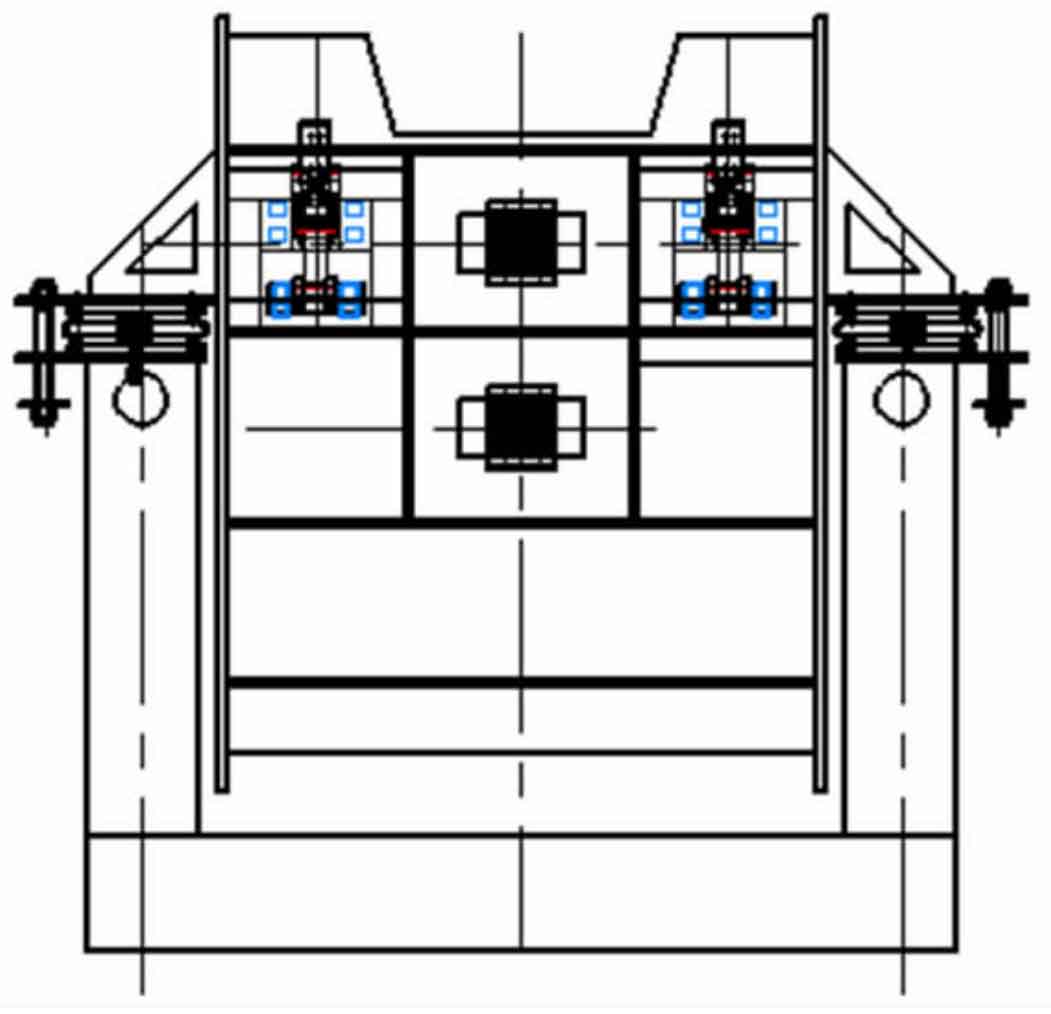

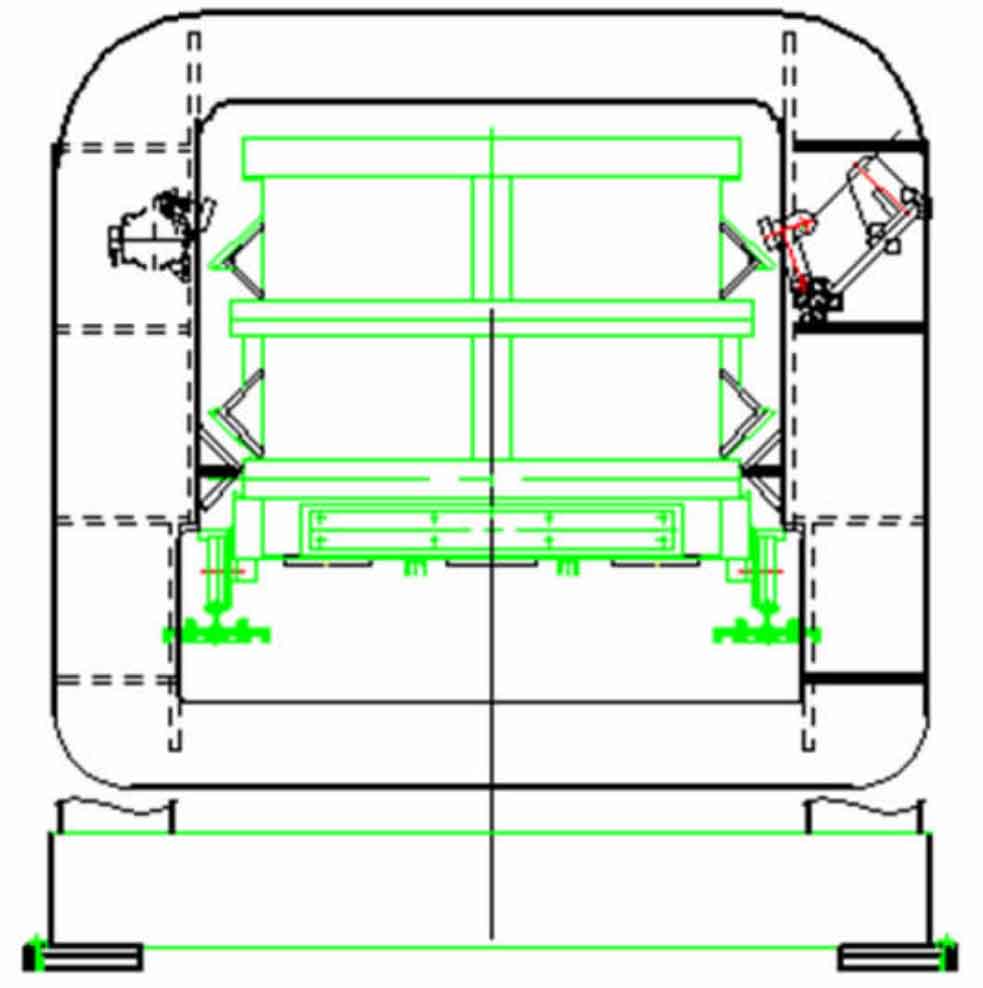

The lost foam casting vibrating table is independently developed by ZHY casting. It adopts a waist holding clamping frame structure similar to Vulcan, with two vibrating motors on both sides. The lost foam casting sand box is compressed through 8 45 ° inclined planes, as shown in Figure 3. The control system is composed of four frequency converters and PLC to control the vibration acceleration, amplitude and angle. On the premise of ensuring that the Yellow mold is not deformed, the molding sand can flow orderly, fill all parts of the model evenly, and maintain a certain compactness.