1.The formation mechanism of semi-solid primary non dendrite particles under the action of rotating magnetic field and the mathematical relationship between the undercooling degree and process parameters were investigated

The effect of Zr particles on the microstructure of semi-solid non dendritic slurry was elucidated: adding Zr element to Mg nd Zn alloy, the main formation mechanism of primary particles in the process of electromagnetic stirring was dendrite fusing to form fine and round primary particles directly in the melt.

2.The strengthening mechanism of rheo squeeze casting Mg nd Zn alloy was revealed. The precipitates of T6 nz30k alloy are mainly β″ phase and β′ phase. The strengthening contribution of yield strength mainly comes from grain boundary strengthening and precipitation strengthening. Compared with conventional squeeze casting alloy, rheo squeeze casting alloy has stronger precipitation strengthening effect, so it has higher comprehensive mechanical properties.

3.A new electromagnetic stirring rheo squeeze casting process for Mg nd Zn alloy was developed. The optimum range of process parameters was obtained. The microstructure and mechanical properties of the alloy were significantly refined.

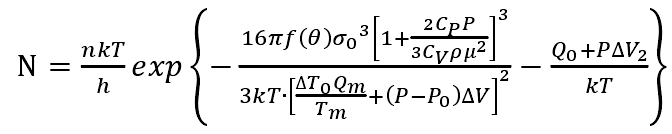

4.The mathematical relationship among pressure, undercooling and nucleation rate in rheo squeeze casting of nz30k alloy was investigated

It is found that the nucleation rate of nz30k alloy increases with the increase of pressure when the undercooling is less than 13.8 ℃.