Forming process of rheo squeeze casting

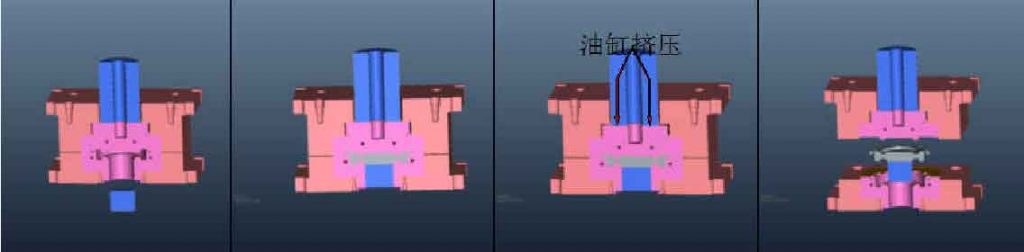

Rheo squeeze casting mainly includes the following processes: 1 Mold closing; ② grouting: pouring the semi-solid metal slurry prepared on-line into the barrel with heating and temperature regulating device; ③ barrel return and docking with the mold: the barrel accurately moves to the center of the mold gate through the oil cylinder, and docking the barrel with the mold through the lifting oil cylinder; ④ extrusion injection: starting the injection oil cylinder to push the liquid metal for filling and forming; ④ injection of liquid metal into the mold through the lifting oil cylinder; ⑤ Pressure maintaining and secondary extrusion: after the liquid metal is filled and maintained for a proper time, start the pressure cylinder to push the upper die for secondary extrusion forming; ⑥ mold opening and ejection: exit the secondary pressure cylinder, lock the cylinder, raise the template, start the injection cylinder to push the workpiece upward to complete a forming process. As shown in the figure is the die forming process diagram.

Scheme of experimental system for rheo squeeze casting

After degassing and slag removal, the semi-solid slurry is produced by lspsf process with PLC automatic control of process parameters and sent to the accumulator. After the semi-solid slurry reaches the forming temperature requirement, it is transferred to the barrel of semi-solid vertical squeeze casting machine, and then the rheo squeeze casting process is carried out by using automatic program control equipment. After the completion of squeeze casting, the microstructure and mechanical properties of the squeeze casting parts were tested and analyzed. The microstructure and mechanical properties of some parts after heat treatment were analyzed. Finally, the forming mechanism was analyzed.