Innovations in spheroidal graphite cast iron, also known as ductile iron, have been increasingly focused on enhancing its strength and ductility. These two properties are critical in a wide range of engineering applications, from infrastructure to automotive manufacturing. Let’s explore some of the key innovations and research directions in this area:

Alloying for Improved Properties

- Adding Nickel and Copper: These elements can enhance strength without significantly reducing ductility. Nickel, in particular, can improve corrosion resistance, which is valuable for pipes and outdoor structures.

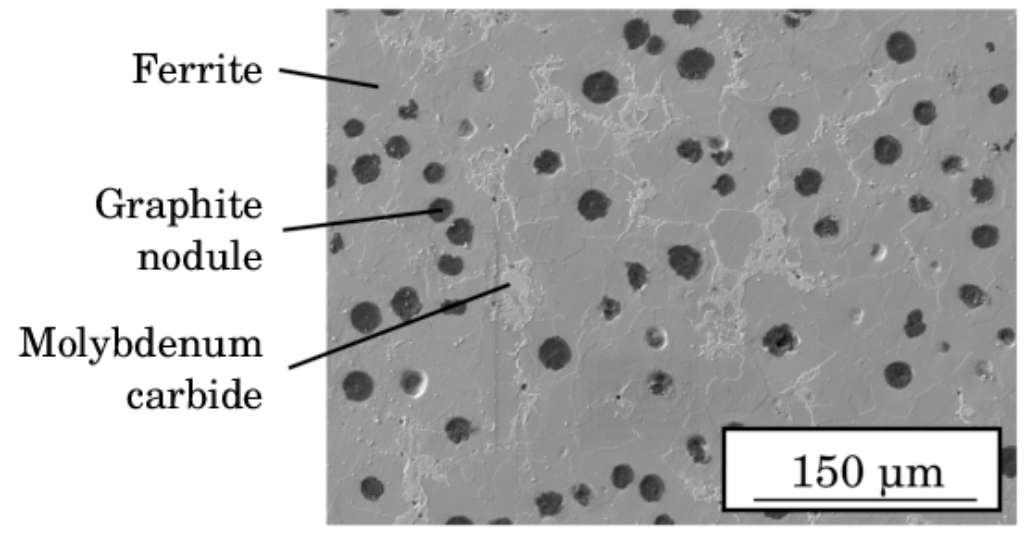

- Molybdenum and Chromium: These elements can increase the hardenability and wear resistance of spheroidal graphite cast iron. They’re particularly useful in automotive applications where high strength and endurance are required.

Advanced Heat Treatment Techniques

- Austempering: This heat treatment process can significantly improve both strength and ductility. spheroidal graphite cast iron treated by austempering (often referred to as ADI – Austempered Ductile Iron) undergoes a transformation to a bainitic microstructure, offering an excellent combination of strength, toughness, and wear resistance.

- Dual Matrix Structures (DMS): This involves creating a microstructure that contains both ferrite and pearlite in controlled proportions, optimizing the balance between strength and ductility.

Microstructural Control

- Graphite Nodule Shape and Size: Innovations in controlling the shape and distribution of graphite nodules within the iron matrix have a direct impact on mechanical properties. Finer and more evenly distributed nodules can enhance both strength and ductility.

- Matrix Refinement: Techniques to refine the grain structure of the matrix phase can lead to improved mechanical properties. This includes controlling the cooling rate and chemical composition.

Computational Materials Engineering

- Predictive Modeling: Using advanced simulation tools to predict how changes in composition and processing affect spheroidal graphite cast iron’s properties. This allows for more efficient development of new alloys and heat treatment processes.

- Machine Learning: Leveraging machine learning algorithms to analyze data from spheroidal graphite cast iron processing and performance, optimizing manufacturing parameters for desired properties.

Sustainable Manufacturing Practices

- Reduced Energy Processes: Developing casting and heat treatment processes that consume less energy, making the production of spheroidal graphite cast iron more environmentally friendly.

- Recycling and Lifecycle Analysis: Enhancing the recyclability of spheroidal graphite cast iron products and analyzing their lifecycle for environmental impact.

Applications of Innovations

- Automotive Industry: High-strength, ductile spheroidal graphite cast iron is used for manufacturing critical components like crankshafts, gearboxes, and suspension systems.

- Infrastructure: Enhanced spheroidal graphite cast iron is ideal for applications like bridges and pipelines, where both strength and ductility are essential to withstand environmental stresses.

- Renewable Energy: Components such as wind turbine hubs and gearbox housings benefit from the improved strength and fatigue resistance of innovative spheroidal graphite cast iron.

Conclusion

Innovations in Spheroidal Graphite Cast Iron are crucial in meeting the evolving demands of various industries for materials that combine high strength with good ductility. These advancements not only extend the range of applications for spheroidal graphite cast iron but also contribute to more sustainable manufacturing practices. The continued exploration of alloying, heat treatment, and microstructural control is likely to yield even more impressive materials in the future.