The high chromium cast iron carbon steel bimetallic casting lining plate was installed in the wet ball mill, and the wear resistance of the casting lining plate was tested under full load and full working conditions. It was compared with the original alloy steel casting lining plate of the concentrator in terms of installation and operation effect, appearance and weight loss of the lining plate. The mechanism of corrosion and wear of the materials in service was also studied by analyzing the microstructure of the worn samples.

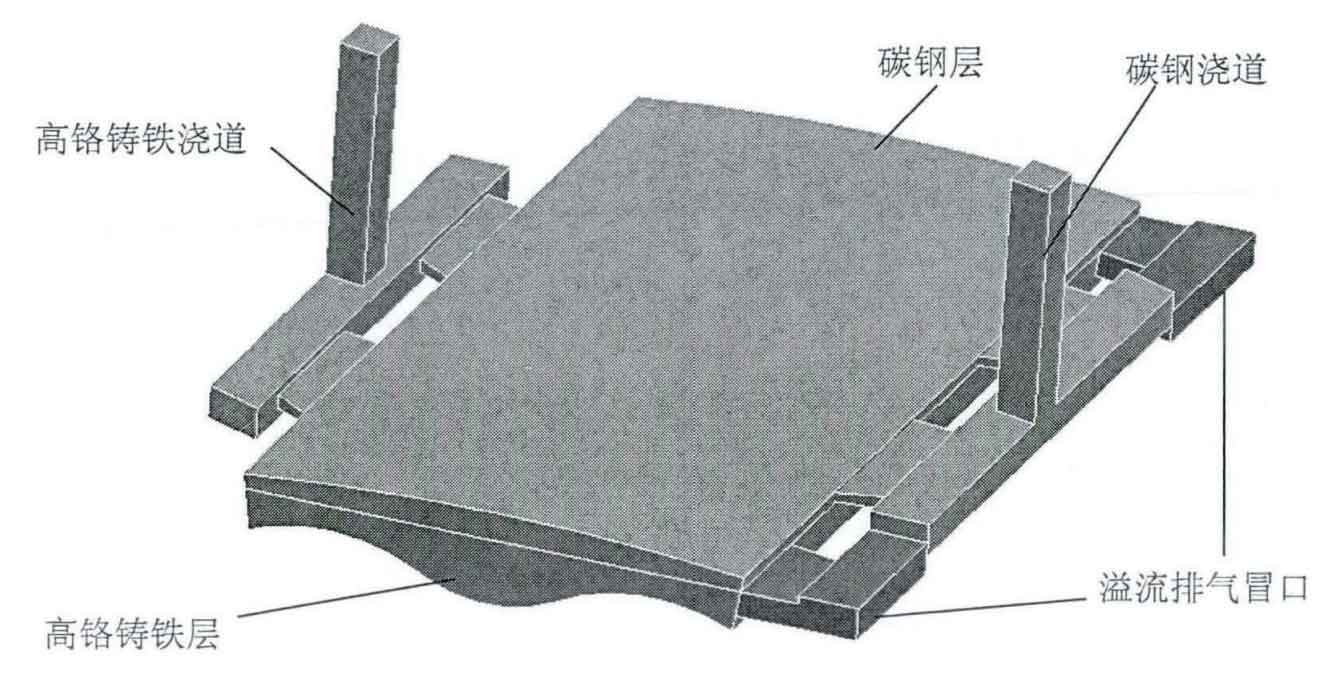

The high chromium cast iron and carbon steel bimetallic casting liner was successfully developed by the bimetallic liquid lost foam casting method, and successfully used in Φ The 3.6m iron ore wet ball mill has completed nine months of full working condition test. In the service environment of wet ball mill, bimetallic casting liner has high strength and wear resistance of eutectic high chromium cast iron, as well as high primary property and high ductility of eutectoid steel. The weight loss results show that the relative wear resistance coefficient of bimetallic casting liner is three times that of original alloy steel casting liner.