The density of titanium alloy is small, and the static head of feeding in the mold during vacuum casting is small, resulting in poor fluidity and feeding ability of titanium, and the sensitivity of titanium to hydrogen, oxygen, nitrogen and other interstitial elements is large, and the casting defects of gas shrinkage cavity are easily formed during the casting and solidification process of titanium liquid. The gating system was simulated by simulation software to determine the gating system suitable for producing the investment casting.

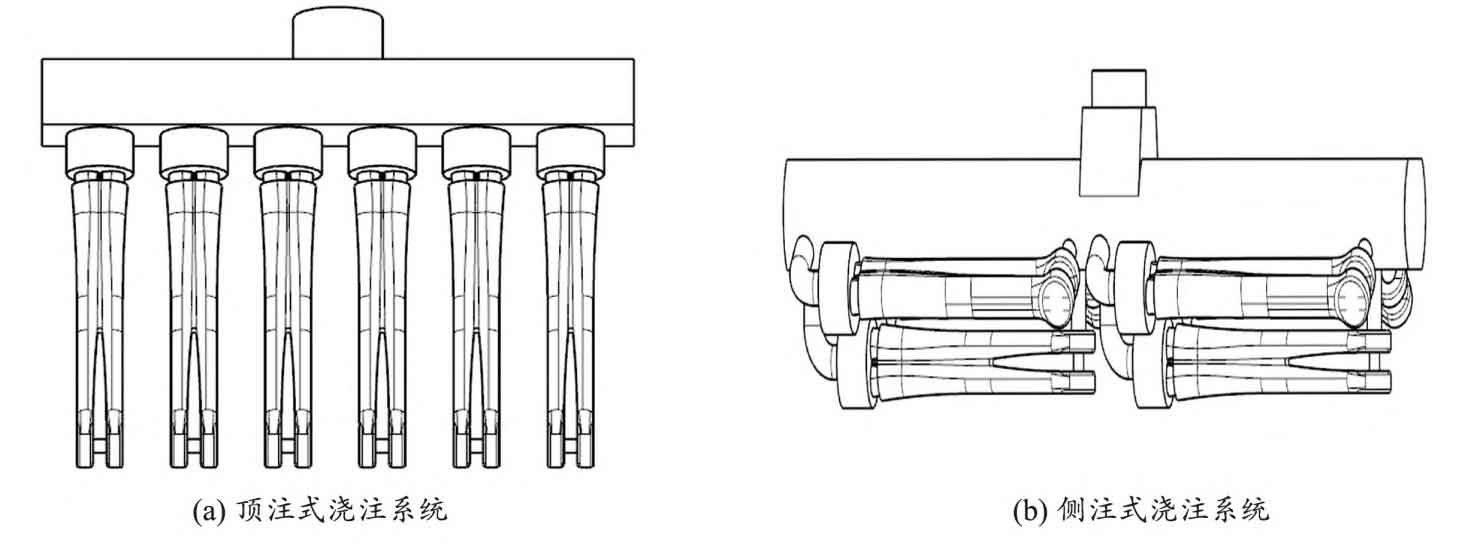

According to the structural characteristics of the casting products and the casting method of investment casting, the investment casting process plan I is designed by using the sequential solidification theory, as shown in Figure (a), that is, the top-pouring pouring system is adopted, and the long rod is placed in the same direction as the gravity direction. The thick end part is placed at the top, the inner runner acts as the gating riser, and the anti-deformation support is set at the end of the rod, φ An open gating system with a 10 mm hole not cast and a section ratio of 1 ∶ 1.02 ∶ 2.06 for the gating system facilitates sequential solidification. The investment casting process plan II is designed by using the proportional solidification theory, as shown in Figure (b). The side pouring system is adopted, the long rod is laid horizontally, and the inner runner is set at the end of the rod φ Two 10mm ends reduce the filling and feeding process of titanium alloy, and the open gating system with a section ratio of 1 ∶ 1.02 ∶ 1.5 is convenient for achieving balanced solidification. Simulate the two schemes, analyze the temperature field and stress field during solidification shrinkage, compare the location of shrinkage cavity and porosity and the stress situation, and determine the gating system scheme most suitable for the production of the investment casting.