1. Introduction

In the automotive industry, lightweight design has become a crucial trend to improve fuel efficiency, reduce emissions, and enhance overall vehicle performance. The steering knuckle, a key component of the vehicle’s chassis, plays a vital role in ensuring safe and stable driving. However, traditional steering knuckles made of ductile cast iron are relatively heavy, which goes against the lightweight development trend. Therefore, finding ways to reduce the weight of the steering knuckle without sacrificing its performance is of great significance.

Topology optimization is a powerful tool in the field of engineering design. It can find the optimal material distribution within a given design space, resulting in a structure with the best performance – to – weight ratio. Squeeze casting, on the other hand, is an advanced manufacturing process that can produce components with high – quality, dense microstructures and excellent mechanical properties. Combining topology optimization with squeeze casting provides a new approach to achieving the lightweight design of steering knuckles.

2. Research Background

2.1 The Importance of Steering Knuckle in Vehicles

The steering knuckle is a critical part of the vehicle’s suspension and steering system. It connects various components such as the wheel, suspension arms, and steering linkages. During vehicle operation, the steering knuckle is subjected to complex and diverse loads, including forces from braking, acceleration, cornering, and road irregularities. These loads require the steering knuckle to have high strength, good impact resistance, and sufficient stiffness to ensure accurate steering and reliable vehicle handling.

2.2 Current Materials and Manufacturing Processes for Steering Knuckles

Currently, many steering knuckles are made of ductile cast iron through sand casting. Ductile cast iron has relatively high strength and wear – resistance, but its density is relatively large, which leads to a heavyweight of the steering knuckle. With the increasing demand for vehicle lightweighting, lightweight materials such as aluminum alloys are gradually being considered for steering knuckle manufacturing.

Sand casting, although widely used, has some limitations. It may result in porosity and inhomogeneous microstructures in the castings, affecting the mechanical properties of the final product. Squeeze casting, as an alternative, can overcome these problems to a certain extent. It can produce components with more compact microstructures, higher mechanical properties, and better dimensional accuracy.

2.3 The Role of Topology Optimization in Lightweight Design

Topology optimization has been widely used in various engineering fields for lightweight design. By optimizing the material distribution in a component, it can eliminate unnecessary material while maintaining or even improving the component’s performance. In the case of steering knuckles, topology optimization can help to identify the areas where material can be removed or redistributed, leading to a lighter and more efficient structure.

3. Methodology

3.1 Topology Optimization Theory

3.1.1 The Concept of Topology Optimization

Topology optimization aims to find the best distribution of materials within a defined design space to meet specific performance requirements, such as maximizing stiffness or minimizing compliance. It is different from shape and size optimization, as it focuses on changing the fundamental layout of the structure.

3.1.2 The SIMP Interpolation Model

The Solid Isotropic Material with Penalization (SIMP) model is a commonly used method in topology optimization. It uses a density – based approach, where the density of each element in the finite – element model is treated as a design variable. The model introduces a penalty factor to penalize intermediate density values. As the optimization progresses, the intermediate density values tend to converge to 0 (no material) or 1 (solid material), resulting in a clear – cut structure.

| Parameter | Meaning |

|---|---|

| \(ρ\) | Design variable (element material density) |

| q | Penalty factor (\(q\geq2\), usually \(q = 3\)) |

| \(C_{k(ρ)}\) | The k – th working condition compliance objective function |

| \(C_{k}^{max}\) | The maximum compliance of the k – th working condition |

| \(C_{k}^{min}\) | The minimum compliance of the k – th working condition |

3.1.3 Multi – 工况 Topology Optimization Mathematical Model

Since the steering knuckle is subjected to different loading conditions during vehicle operation, multi – 工况 topology optimization is necessary. A common objective function for steering knuckle topology optimization is to maximize stiffness. In this study, considering the actual situation, it is assumed that the relative importance of each working condition is the same. The mathematical model for multi – 工况 topology optimization of the steering knuckle is as follows: \(\left\{\begin{array}{l} min C(x)=U^{T}KU=\left\{\sum_{k = 1}^{m}\omega_{k}\left[\frac{c_{k(\rho)}-c_{k}^{min}}{c_{k}^{max}-c_{k}^{min}}\right]^{q}\right\}^{\frac{1}{q}}\\ s.t V(\rho)/V_{0}\leq f\\ \sigma_{j}(x)-\sigma_{0}<0 \end{array}\right.\) Where K and U are the element stiffness and displacement matrices, \(m = 5\) is the total number of load cases, \(\omega_{k}=1\) is the weight of the k – th load case, q is the penalty factor (\(q\geq2\), usually \(q = 3\)), \(C_{k(ρ)}\) is the compliance objective function of the k – th load case, \(C_{k}^{max}\) and \(C_{k}^{min}\) are the maximum and minimum compliances of the k – th load case respectively, \(\rho\) is the design variable (element material density), \(V_{0}\) and \(V(\rho)\) are the volumes of the structure before and after optimization, \(f = 30\%\) is the volume constraint fraction, \(\sigma_{j}(x)\) is the stress at the j – th node, and \(\sigma_{0}=230MPa\) is the stress limit.

3.2 Finite Element Model Establishment

3.2.1 Model Creation

Based on the model of the ductile cast iron steering knuckle, an aluminum alloy steering knuckle maximum solid model was established while maintaining the original assembly relationship. The model was then imported into HyperMesh for mesh division. The mesh size was set to 1mm, which is the minimum size of the model. In the model, the circular part with a mating surface is a non – designable area, and the gray area is the design space for topology optimization.

[Insert a picture here showing the aluminum alloy steering knuckle model before and after mesh division, with the non – designable area and design space clearly marked]

3.2.2 Material Properties Definition

The elastic modulus of the aluminum alloy steering knuckle was defined as 72.4GPa, the Poisson’s ratio as 0.33, and the density as \(2700kg/m^{3}\). These material properties are important parameters for finite – element analysis and affect the mechanical behavior of the steering knuckle under different loads.

3.2.3 Loading Conditions and Constraints

Five working conditions were considered in this study, including 4 – times full load, single – side over – curb, over – curb, forward braking, and forward acceleration. Since the steering knuckle is not completely stationary relative to the vehicle body under different load conditions, the inertial release method was used. In this method, the inertial force balances the external force, and the node displacement is ignored. Virtual constraint points are automatically selected by the software calculation program. Loads were applied directly at the installation points, and the positions of the installation points and the applied loads are shown in Table 1.

| Description | Loading Conditions | ||||

|---|---|---|---|---|---|

| 4 – times Full Load | Single – side Over – curb | Over – curb | Forward Braking | Forward Acceleration | |

| Steering knuckle and wheel – center connection point \((0, – 814,0)\) | \(F_{x}=-472N\) | \(F_{x}=9760N\) | \(F_{x}=9726N\) | \(F_{x}=12208N\) | \(F_{x}=-6136N\) |

| \(F_{y}=68N\) | \(F_{y}=18N\) | \(F_{y}=40N\) | \(F_{y}=125N\) | \(F_{y}=-4N\) | |

| \(F_{z}=19586N\) | \(F_{z}=14702N\) | \(F_{z}=14724N\) | \(F_{z}=27741N\) | \(F_{z}=4888N\) | |

| \(T_{x}=18612N\cdot mm\) | \(T_{x}=4439N\cdot mm\) | \(T_{x}=11370N\cdot mm\) | \(T_{x}=418772N\cdot mm\) | \(T_{x}=-2320N\cdot mm\) | |

| \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | |

| \(T_{z}=448N\cdot mm\) | \(T_{z}=-18N\cdot mm\) | \(T_{z}=-21N\cdot mm\) | \(T_{z}=-94163N\cdot mm\) | \(T_{z}=-60N\cdot mm\) | |

| Steering knuckle and lower – control – arm connection point \(( – 10.5,-773.2,-120.2)\) | \(F_{x}=908N\) | \(F_{x}=-9494N\) | \(F_{x}=-6946N\) | \(F_{x}=-10829N\) | \(F_{x}=8222N\) |

| \(F_{y}=5077N\) | \(F_{y}=5756N\) | \(F_{y}=7579N\) | \(F_{y}=1502N\) | \(F_{y}=1609N\) | |

| \(F_{z}=-1067N\) | \(F_{z}=-1625N\) | \(F_{z}=-1990N\) | \(F_{z}=-683N\) | \(F_{z}=551N\) | |

| \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | |

| \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | |

| \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | |

| Steering knuckle and tie – rod connection point \((143.4,-748.8,-17.2)\) | \(F_{x}=177N\) | \(F_{x}=-269N\) | \(F_{x}=-609N\) | \(F_{x}=73N\) | \(F_{x}=-12N\) |

| \(F_{y}=906N\) | \(F_{y}=-1683N\) | \(F_{y}=-3960N\) | \(F_{y}=549N\) | \(F_{y}=-60N\) | |

| \(F_{z}=-178N\) | \(F_{z}=304N\) | \(F_{z}=765N\) | \(F_{z}=-60N\) | \(F_{z}=-1N\) | |

| \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | |

| \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | |

| \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | |

| Steering knuckle and shock – absorber connection point \((3.72,-691.89,123.58)\) | \(F_{x}=-619N\) | \(F_{x}=4N\) | \(F_{x}=-2171N\) | \(F_{x}=2331N\) | \(F_{x}=-2079N\) |

| \(F_{y}=-6051N\) | \(F_{y}=-4091N\) | \(F_{y}=-3658N\) | \(F_{y}=-2042N\) | \(F_{y}=-1545N\) | |

| \(F_{z}=-18126N\) | \(F_{z}=-13166N\) | \(F_{z}=-13284N\) | \(F_{z}=-6066N\) | \(F_{z}=-5222N\) | |

| \(T_{x}=885833N\cdot mm\) | \(T_{x}=490924N\cdot mm\) | \(T_{x}=556935N\cdot mm\) | \(T_{x}=344352N\cdot mm\) | \(T_{x}=243874N\cdot mm\) | |

| \(T_{y}=103796N\cdot mm\) | \(T_{y}=310901N\cdot mm\) | \(T_{y}=-498896N\cdot mm\) | \(T_{y}=1088870N\cdot mm\) | \(T_{y}=-779369N\cdot mm\) | |

| \(T_{z}=-81356N\cdot mm\) | \(T_{z}=-87463N\cdot mm\) | \(T_{z}=72772N\cdot mm\) | \(T_{z}=-208086N\cdot mm\) | \(T_{z}=112372N\cdot mm\) | |

| Steering knuckle and brake – caliper connection point \(( – 72.8,-789.0,-9.3)\) | \(F_{x}=0N\) | \(F_{x}=0N\) | \(F_{x}=0N\) | \(F_{x}=-3779N\) | \(F_{x}=0N\) |

| \(F_{y}=0N\) | \(F_{y}=0N\) | \(F_{y}=0N\) | \(F_{y}=-135N\) | \(F_{y}=0N\) | |

| \(F_{z}=-10N\) | \(F_{z}=-10N\) | \(F_{z}=-10N\) | \(F_{z}=-20727N\) | \(F_{z}=-10N\) | |

| \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=0N\cdot mm\) | \(T_{x}=95844N\cdot mm\) | \(T_{x}=0N\cdot mm\) | |

| \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=0N\cdot mm\) | \(T_{y}=-1138150N\cdot mm\) | \(T_{y}=0N\cdot mm\) | |

| \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=0N\cdot mm\) | \(T_{z}=-10068N\cdot mm\) | \(T_{z}=0N\cdot mm\) |

3.3 Topology Optimization Analysis and Results

3.3.1 Optimization Task Setting

In the creation of the steering knuckle topology optimization task, the multi – 工况 comprehensive compliance was set as the objective function, and the volume fraction was set as the optimization constraint, with its upper limit set to 30% (i.e., the volume ratio after optimization /volume before optimization ≤ 0.3). To ensure the optimized structure met the strength requirements, the stress after optimization was restricted to be less than 230 MPa. The demolding method was set as bi – directional demolding, and the demolding direction is shown in Figure 1.

3.3.2 Optimization Results

The optimization results indicated that after 29 iterations, the compliance gradually converged and finally stabilized. The compliance change curve is presented in Figure 2. By setting the element density threshold to 0.3 and retaining the elements with a relative density > 0.3, the topology – optimized result of the steering knuckle was obtained, as shown in Figure 3. In the figure, the dark – colored area represents the retained structure, while the remaining areas are those available for further structural optimization design.

4. Structure Design of Squeeze Cast Aluminum Alloy Steering Knuckle

4.1 Topology – optimized Structure Design

The topology – optimized result was smoothed and imported into a 3D software for further structural optimization. The following measures were taken:

- As the optimization area on the back of the steering knuckle was large, the entire surface was lowered by 5 mm. Additionally, the planes around the two holes connected to the brake caliper were further lowered by 5 mm (area a in Figure 4).

- For area b with a relatively deep optimization result, to ensure the structural strength of the steering knuckle, a slot was made at a distance of approximately 8 mm from the boundary for material reduction.

- Due to the deep optimization dimension in area c, a convex platform with a height of approximately 3 mm was set on the side of the steering knuckle, and one through – hole with a diameter of 10 mm and one blind – hole with a diameter of 5 mm were created. This structure could also facilitate better gas exhaust during the squeeze – casting process.

- In area d, where the central position had significant optimization, to ensure strength, material was reduced by approximately 5 mm on both sides, and the assembly relationship with surrounding parts was also achieved.

- The areas on both sides of the shock – absorber connection point (area e) were also subjected to material reduction treatment, changing from a convex to a concave shape.

- Affected by the bi – directional demolding, there was a large – scale optimization area on the front of the steering knuckle (area f in Figure 4). The area around the central hole was lowered by approximately 10 mm on the entire surface.

4.2 Squeeze – casting Forming Structure Design

Considering the requirements of demolding in the squeeze – casting process, the steering knuckle structure model was subjected to demolding treatment with a demolding angle of 5°, and the parting surface was determined. Some convex platforms and grooves were designed to play a positioning role in subsequent machining. Since a vertical squeeze – casting machine was used and the molten metal was poured from the back to the front, a flow – guiding rib structure was designed to ensure the smooth and stable flow of the molten metal. The process structure design of the squeeze – cast steering knuckle is shown in Figure 5.

5. Finite Element Strength Verification

The aluminum alloy steering knuckle model was analyzed by the finite element method under the same working conditions. The stress nephograms under each working condition are shown in Figure 6, and the maximum stress values under each working condition are presented in Table 2.

| Working Condition | 4 – times Full Load | Single – side Over – curb | Over – curb | Forward Braking | Forward Acceleration | Target Requirement |

|---|---|---|---|---|---|---|

| Maximum Stress /MPa | 75.220 | 161.185 | 142.822 | 169.328 | 106.080 | ≤ 230 |

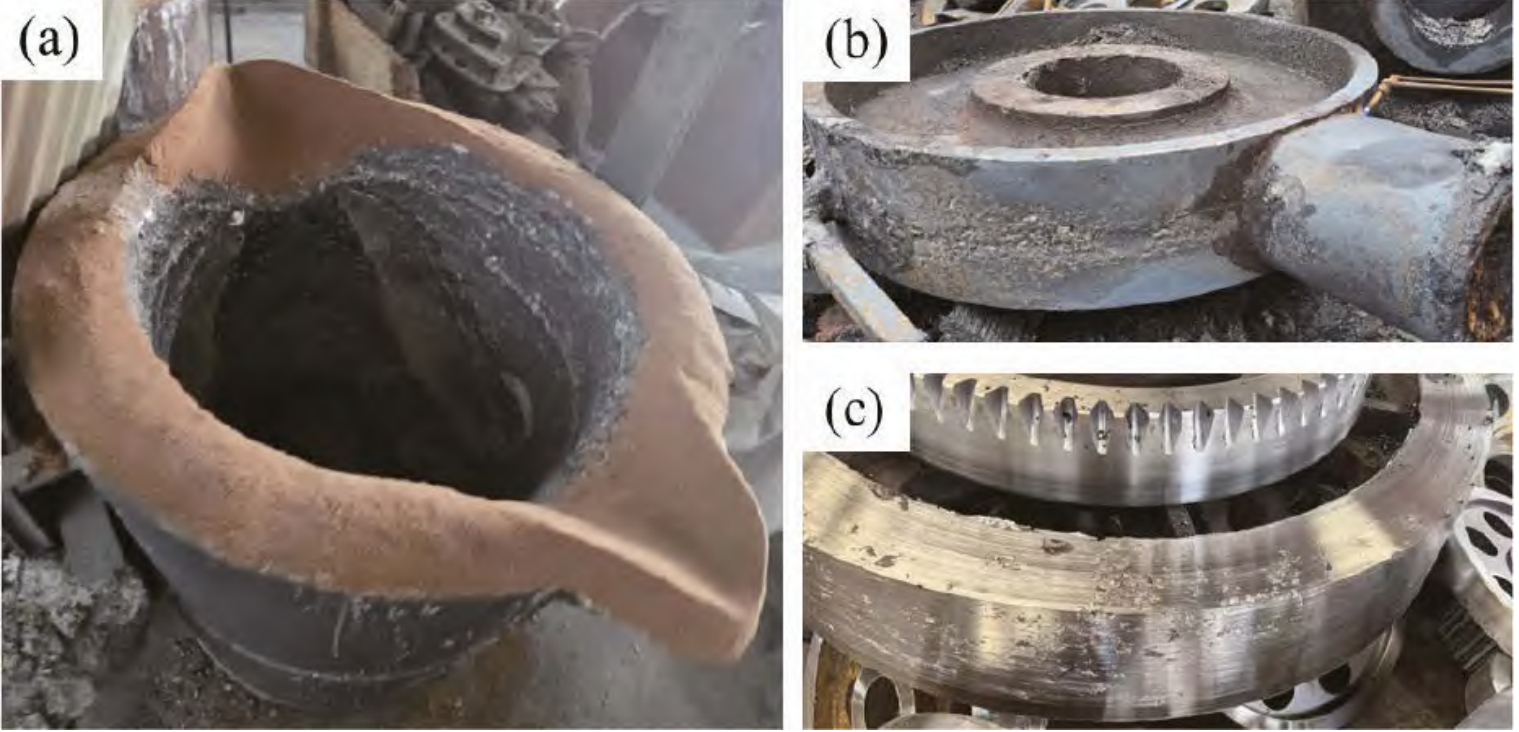

It can be seen from Figure 6 that the maximum stress of the structurally optimized aluminum alloy steering knuckle was much less than the yield strength of the aluminum alloy (230 MPa), and the stress distribution was relatively uniform without obvious stress concentration. This indicates that the optimized steering knuckle meets the structural strength requirements. Moreover, compared with the ductile cast iron steering knuckle, the aluminum alloy steering knuckle achieved a weight reduction of 60.9%, showing a significant lightweight effect. The physical product comparison between the two is shown in Figure 7.

6. Mechanical Property Verification

6.1 Heat Treatment Process

To eliminate internal organizational segregation, improve the microstructure, and enhance mechanical properties, heat treatment is generally required for steering knuckle castings. The T6 heat – treatment process for the steering knuckle casting was 540 °C × 6 h for solution treatment, quenched in water at 60 °C for 5 min, and aged at 175 °C × 4 h.

6.2 Mechanical Property Testing

Tensile specimens were taken from the heat – treated steering knuckle for mechanical property testing. The sampling location is shown in Figure 8, and the test results are presented in Table 3.

| Specimen Number | Tensile Strength /MPa | Yield Strength /MPa | Elongation / % |

|---|---|---|---|

| 2 – 1 | 316.57 | 256.93 | 8.57 |

| 2 – 2 | 305.49 | 247.33 | 6.32 |

| Average Value | 311.03 | 252.13 | 7.45 |

| Required Value | ≥ 290 | ≥ 220 | ≥ 6 |

The test results demonstrated that the mechanical properties of the heat – treated steering knuckle met the requirements, with the average tensile strength, yield strength, and elongation all greater than the specified values.

7. Discussion

7.1 The Significance of Combining Topology Optimization and Squeeze Casting

The combination of topology optimization and squeeze casting provides a more efficient way to achieve the lightweight design of steering knuckles. Topology optimization can effectively remove unnecessary material and optimize the structure layout, while squeeze casting can ensure the high – quality manufacturing of the optimized structure, resulting in a lightweight and high – performance steering knuckle.

7.2 The Influence of Different Parameters on the Optimization Results

Parameters such as the penalty factor in the SIMP model, volume constraint fraction, and loading conditions have significant impacts on the topology – optimization results. For example, a larger penalty factor can make the density distribution more concentrated at 0 and 1, but it may also lead to slower convergence. The volume constraint fraction directly determines the amount of material reduction, and different loading conditions can change the stress distribution and thus the optimal material layout.

7.3 The Application Prospect and Challenges of This Research

This research has broad application prospects in the automotive industry. The lightweight steering knuckle developed can not only improve the fuel efficiency and performance of vehicles but also contribute to environmental protection. However, there are still some challenges. For example, the cost of aluminum alloy materials and the complex squeeze – casting process may limit its large – scale application. Further research is needed to reduce costs and improve production efficiency.

8. Conclusion

- A mathematical model for the topology optimization of the steering knuckle was established based on the variable – density topology optimization method. The static multi – 工况 topology optimization of the maximum solid model of the steering knuckle was carried out using the HyperMesh finite – element analysis software. After 29 iterations, the compliance gradually converged and stabilized.

- Based on the topology – optimized results, the structure of the steering knuckle was optimized, and combined with the squeeze – casting process, the structure of the steering knuckle was redesigned. The strength verification of the newly designed aluminum alloy steering knuckle model showed that the maximum stress under each working condition was much less than the yield strength, and the weight was reduced by 60.9% compared with the ductile cast iron steering knuckle.

- The T6 heat – treatment of the steering knuckle casting and the mechanical property test results showed that the average tensile strength of the samples taken from the body was 311.03 MPa, the yield strength was 252.13 MPa, and the elongation was 7.45%, all of which were greater than the specified values of the product and met the product performance requirements.