As the core component of the engine, the cylinder block has complex structure, high precision requirements and difficult forming. lost foam casting cylinder block has the characteristics of flexible casting structure design, no sand core, convenient cleaning, high production efficiency and low cost. With the development of lost foam casting technology, the lost foam mold has met the requirements of casting the cylinder block. The white mold with the same shape as the cylinder block is manufactured through the full-automatic pre foaming machine, with high dimensional accuracy. When the pattern is filled with sand and vibrated, it can solve the problems that it is difficult to fill sand in the oil channel, water channel and boss in the cylinder. At the same time, the expected filling effect can be obtained by adjusting the negative pressure and other parameters, which is especially suitable for the casting of cylinder block. ProCAST software is used to simulate the mold filling and solidification process of lost foam casting cylinder block. By analyzing the simulation results, the original process is optimized to eliminate the defects such as unstable mold filling, shrinkage porosity and shrinkage cavity, and improve the qualified rate of castings.

(1) The production of cast iron cylinder block by lost foam casting process has the characteristics of simple process, no sand core, convenient cleaning, high production efficiency, low cost and high dimensional accuracy. It can effectively solve the problems of sand filling and mass production.

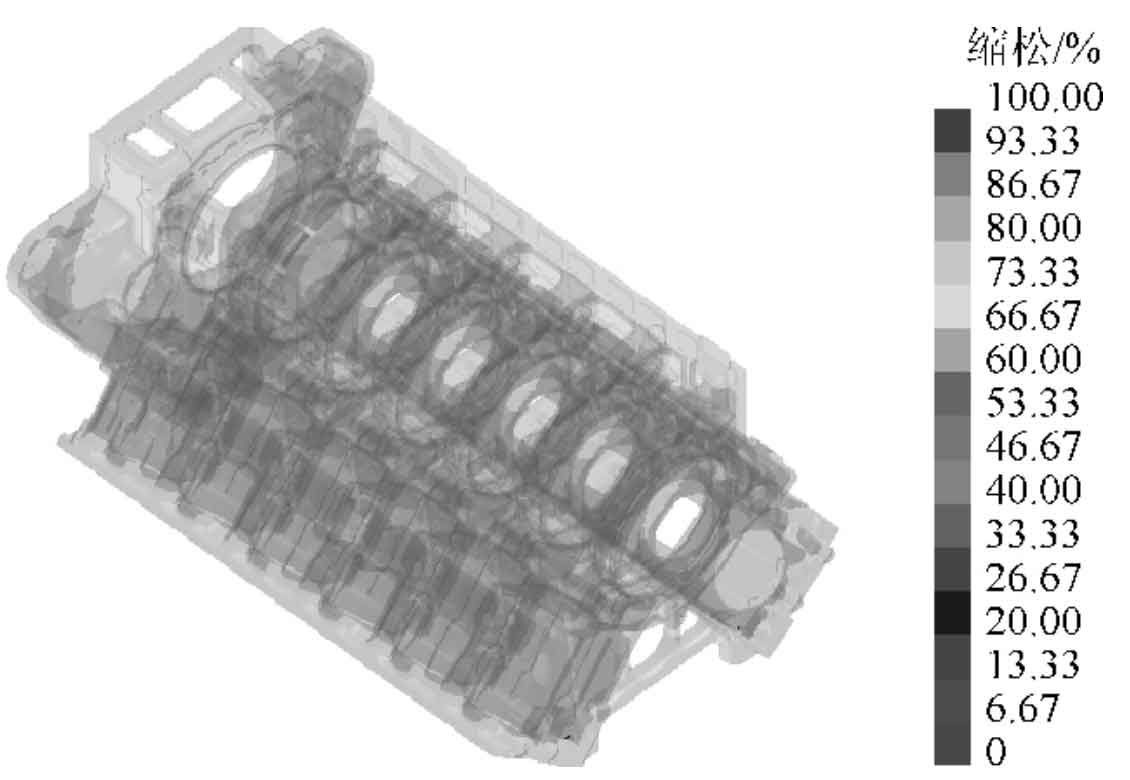

(2) To simulate and analyze the original process of lost foam casting cylinder block with ProCAST software, and explain the causes of shrinkage porosity and shrinkage cavity defects at the place with large outer wall thickness. Through the optimization design of the process, the casting filling is stable without shrinkage cavity and porosity defects, and the qualified rate and process yield of the castings are improved.

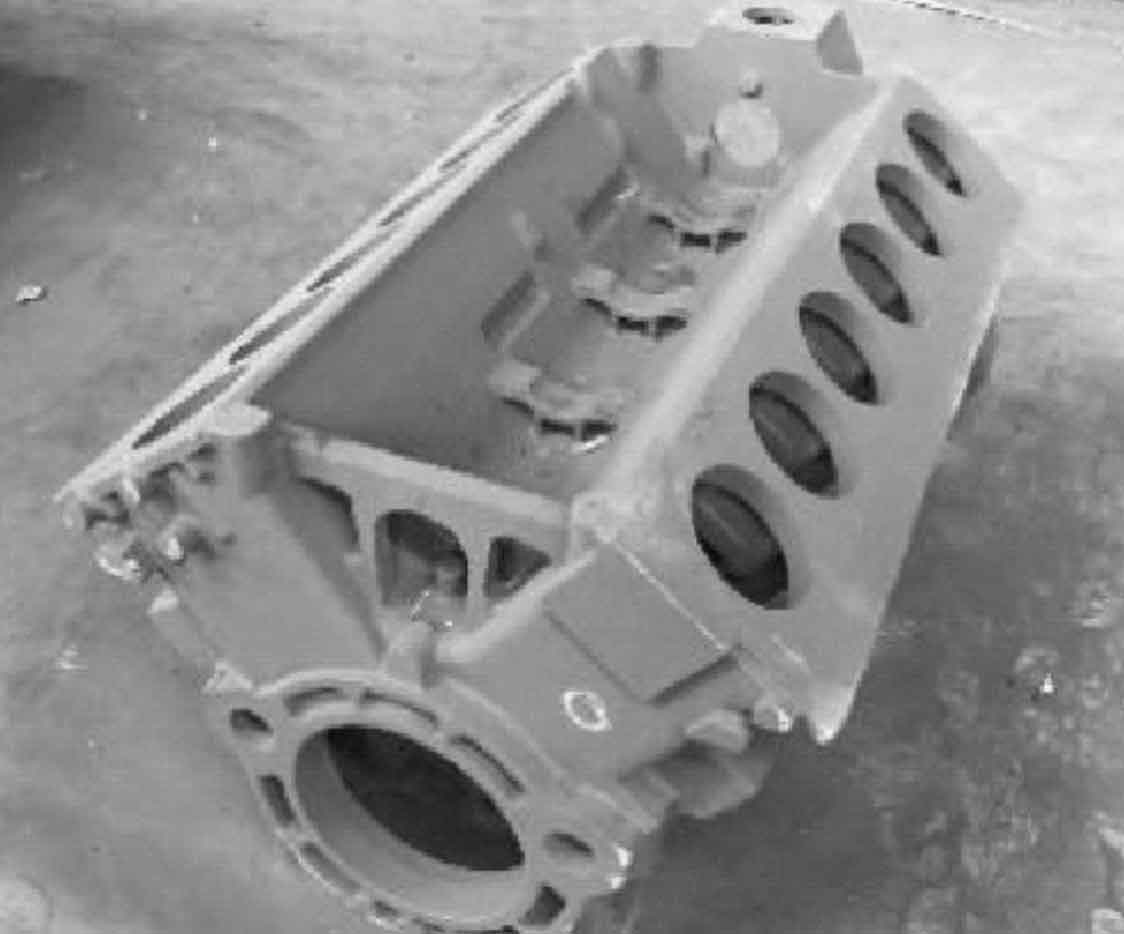

The figure shows the lost foam casting cylinder block produced after changing the pouring position. Through X-ray inspection, there are no shrinkage porosity and shrinkage defects inside, and the mechanical properties also meet the requirements, which greatly improves the qualified rate and process yield of the casting.