This article comprehensively explores the lost foam casting process, including its characteristics, production workflow, and crucial engineering design aspects. By comparing it with traditional sand casting, the advantages of lost foam casting in terms of product complexity, environmental friendliness, cost savings, and quality are highlighted. The detailed engineering design of the pattern making area and the lost foam casting area is presented, along with considerations for fire safety and equipment layout. Future trends and potential improvements in lost foam casting technology are also discussed.

1. Introduction

Lost foam casting has emerged as a significant casting method in the manufacturing industry. Originating from the full mold casting process, it has witnessed remarkable development over the past few decades. With its unique process flow and distinct features, it offers solutions to many challenges faced by traditional casting techniques. This article delves into the details of lost foam casting, aiming to provide a comprehensive understanding of its technology and engineering design.

2. Lost Foam Casting Process Characteristics

2.1 Process Overview

Lost foam casting involves creating a model cluster by bonding paraffin or foamed resin models similar in size and shape to the final casting. After applying refractory coating and drying, the model cluster is buried in dry quartz sand and vibrated to form a mold. During pouring under negative pressure, the model vaporizes, and the liquid metal fills the space previously occupied by the model. After solidification and cooling, the casting is obtained.

2.2 Comparison with Sand Casting

2.2.1 Design Freedom and Complexity

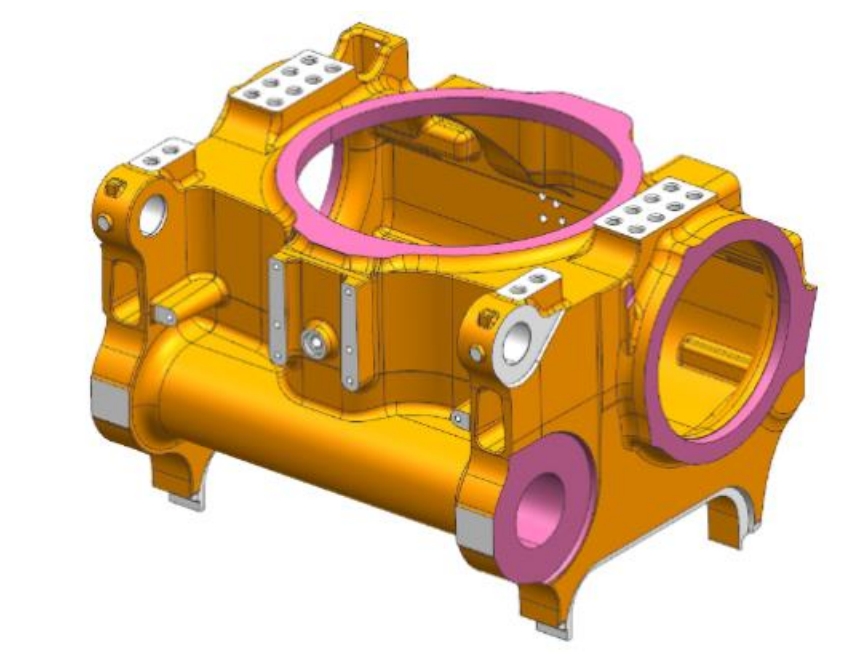

Unlike sand casting, lost foam casting allows for greater design freedom. It can produce castings with complex geometries, such as those with multiple edges, cores, and intricate shapes. This makes it particularly suitable for manufacturing motor housing castings, which are often difficult to produce using traditional methods.

| Casting Method | Design Freedom for Complex Castings |

|---|---|

| Lost Foam Casting | High, suitable for multi-edge, multi-core, and complex geometric shapes |

| Sand Casting | Limited for highly complex shapes |

2.2.2 Environmental Impact

In sand casting, especially when using the cold box or hot box core making processes, harmful fumes are often generated. In contrast, lost foam casting does not require sand cores, eliminating the associated environmental pollution issues. Additionally, the high recycling rate of used sand in lost foam casting (usually over 90%) and the relatively low energy consumption (about 15% energy cost savings) make it more environmentally friendly.

| Casting Method | Sand Core Requirement | Harmful Fume Generation | Used Sand Recycling Rate | Energy Consumption |

|---|---|---|---|---|

| Lost Foam Casting | No | None | > 90% | 15% savings |

| Sand Casting | Required (for some complex castings) | Yes (especially in core making) | Varies | Higher |

2.2.3 Cost and Quality

Lost foam casting can reduce the cost of castings by approximately 30% compared to sand casting. This is mainly due to lower energy consumption, higher used sand recycling rates, and reduced post-processing work. Castings produced by lost foam casting have no flash, burrs, or draft angles, resulting in higher dimensional accuracy and better surface quality. The amount of machining allowance is also significantly reduced, saving processing time and costs.

| Casting Method | Casting Cost | Dimensional Accuracy | Surface Quality | Machining Allowance |

|---|---|---|---|---|

| Lost Foam Casting | 30% reduction | High | Good | Reduced |

| Sand Casting | Higher | Lower | Poorer | More |

2.2.4 Equipment Investment

Generally, the investment in lost foam casting equipment is 30% – 50% lower than that in sand casting. This makes it an attractive option for manufacturers looking to reduce initial investment costs.

| Casting Method | Equipment Investment |

|---|---|

| Lost Foam Casting | 30% – 50% lower than sand casting |

| Sand Casting | Higher |

3. Lost Foam Casting Production Process Flow

3.1 White Area (Pattern Making Area)

The white area is responsible for producing qualified model clusters. It includes processes such as bead pre-foaming, maturation after pre-foaming, mold piece making, mold piece aging, gluing, coating, and drying. Steam pre-foaming is commonly used, and during mold piece making, steam is introduced into the mold to heat the beads until they expand and fill the mold cavity, forming a solid mold piece.

3.2 Gray Area (Molding and Pouring Area)

In the gray area, the model cluster is buried in the sand box, and the sand is vibrated to form a mold. After adding a pouring cup, pouring is carried out under negative pressure. After cooling, the sand box is turned over, and the casting is separated from the sand and sent for further processing.

3.3 Black Area (Melting and Sand Treatment Area)

The black area is similar to the sand casting workshop and includes the melting department, molding department, sand treatment department, and cleaning department. The sand used in lost foam casting is dry sand without any additives, and the sand treatment process involves equipment such as hydraulic turning machines, vibrating sand conveyors, and magnetic separators.

4. Engineering Design of Lost Foam Casting Plant

4.1 Fire Safety Considerations

4.1.1 Pattern Making Workshop

The pattern making workshop uses resin materials that can emit flammable vapors. According to relevant building fire protection codes, the storage room for foam resin beads is classified as a Class A fire hazard area with a fire resistance rating of Grade II. To avoid the entire workshop being classified as Class A, the area of the bead storage room should be strictly controlled to be less than 5% of the workshop area. The production area of the pattern making workshop is classified as a Class C fire hazard area and requires the installation of indoor fire hydrant systems and automatic sprinkler systems.

4.1.2 Lost Foam Casting Workshop

The lost foam casting workshop is classified as a Class D fire hazard area with a fire resistance rating of Grade II. However, due to the use of flammable materials in the process, fire safety measures such as proper layout of fire extinguishing equipment and ensuring good ventilation should still be taken.

4.2 Workshop Layout Design

4.2.1 Pattern Making Workshop Layout

Considering the large area required for processes such as mold piece making and drying but the relatively low height of the equipment, the pattern making workshop is usually designed as a multi-story building. A three-story design is often appropriate. The bead pre-foaming, maturation, and mold piece making equipment are arranged on the first floor to facilitate the supply of steam and the replacement of molds. The top floor can be used as a sunlight room for mold piece aging, taking advantage of solar energy to save energy. The middle floor can be used for white mold coating, drying, and model cluster transmission. A fireproof water curtain should be installed in the corridor connecting the pattern making workshop and the lost foam casting workshop. The boiler room should be located near the pattern making workshop to provide steam for the production process.

4.2.2 Lost Foam Casting Workshop Layout

In the lost foam casting workshop, the layout of the molding line should ensure that the vibrating compaction table is properly positioned to achieve accurate casting dimensions. A vacuum pump room should be set up near the vacuum point to ensure effective vacuum during pouring. The sand treatment department should be located close to the molding area and equipped with cooling equipment to cool the high-temperature sand. Advanced manufacturing lines often adopt an annular layout for molding and sand treatment to improve production efficiency.

5. Future Trends and Challenges in Lost Foam Casting

5.1 Technological Advancements

Ongoing research focuses on improving the quality of foam models, enhancing the performance of refractory coatings, and optimizing the pouring process. New materials and manufacturing techniques are being explored to further reduce costs and improve the quality of castings. For example, the development of advanced foam materials with better strength and thermal stability could potentially improve the dimensional accuracy of castings.

5.2 Automation and Digitalization

The current automation level of the pattern making workshop is relatively low. Future efforts will be directed towards increasing automation in all stages of the lost foam casting process. This includes the use of robotics for mold handling, automated coating systems, and digital control of the pouring process. Digital twin technology could also be applied to simulate and optimize the casting process, reducing trial and error and improving production efficiency.

5.3 Environmental and Energy Efficiency

With increasing environmental awareness, there is a growing demand for more energy-efficient and environmentally friendly casting processes. Lost foam casting has certain advantages in this regard, but further improvements can be made. For example, research is being conducted on more efficient sand recycling methods and the development of environmentally friendly refractory materials to reduce the environmental impact of the process.

6. Conclusion

Lost foam casting offers significant advantages over traditional sand casting in terms of product quality, cost savings, and environmental friendliness. However, to fully realize its potential, attention must be paid to engineering design details, especially fire safety and workshop layout. Looking ahead, continuous technological innovation and the pursuit of automation and environmental protection will be the key to the further development of lost foam casting technology. By addressing these aspects, lost foam casting is expected to play an increasingly important role in the modern manufacturing industry.

In the future, it is necessary to strengthen cooperation between research institutions, manufacturers, and industry associations to promote the sharing of knowledge and experience in lost foam casting. This will accelerate the development and application of new technologies, improve the overall level of the industry, and contribute to the sustainable development of the manufacturing sector.