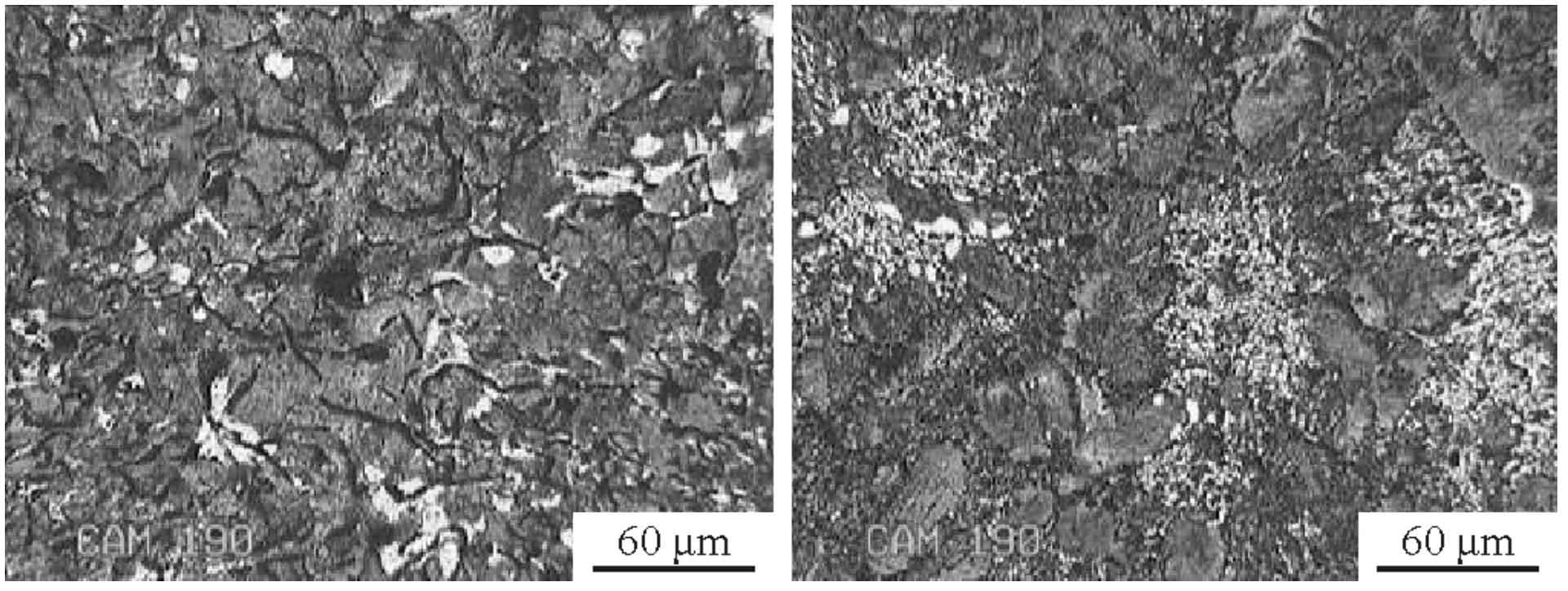

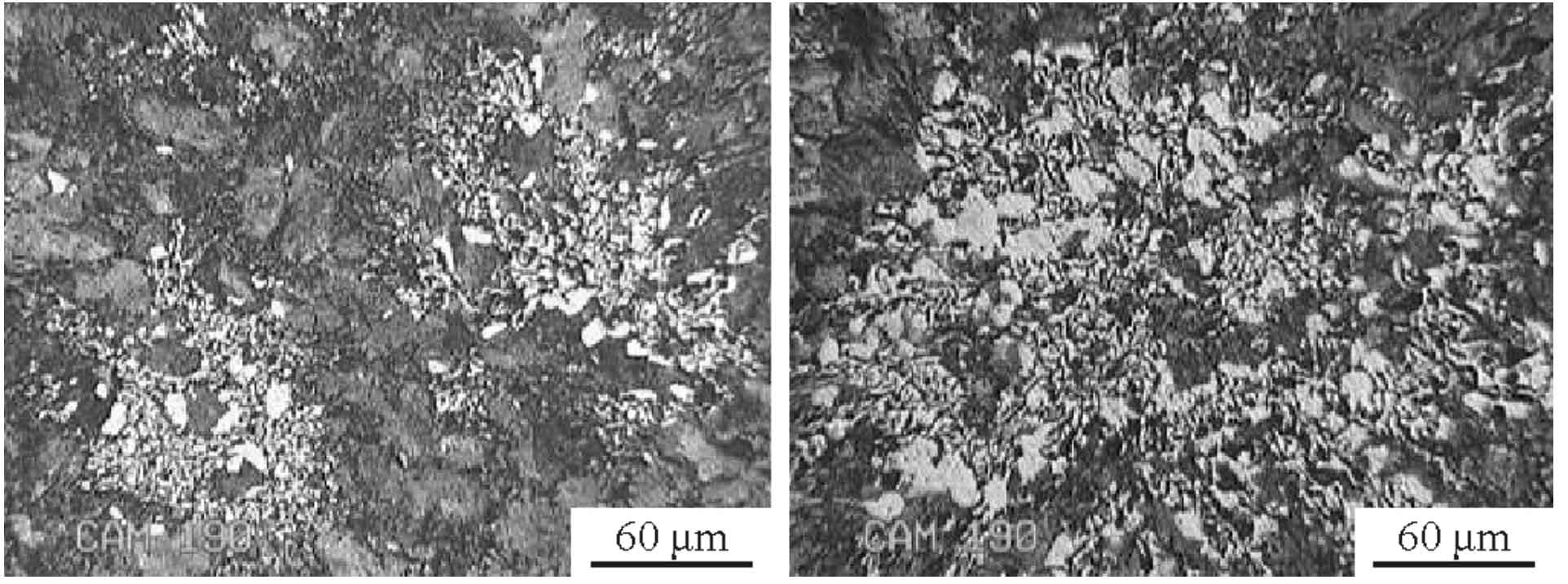

Figure 1 and Figure 2 show HT250 and HT200 gray cast iron respectively Φ The matrix structure of 30mm test bar under the conditions of clay sand mold casting and lost foam casting. The metallographic structure of the two kinds of gray cast iron is mainly composed of pearlite and ferrite, without phosphorus eutectic and other carbides. It can be seen that under the same chemical composition of molten iron and the same pouring conditions, Amount of ferrite in matrix structure of lost foam casting (the white part in Fig. 1b) is more than that of clay sand casting, and the pearlite content is less than that of clay sand casting. According to the pearlite quantity grade of gray cast iron, the pearlite quantity of HT250 lost foam casting is bead 80, while that of clay sand casting is bead 90; that of HT200 lost foam casting is bead 60, while the amount of pearlite cast by clay sand is 70.

The microstructure of gray cast iron mainly depends on eutectoid transformation. If the cooling rate of the casting is fast and the carbon atoms in the supersaturated austenite have no time to diffuse, the austenite will be transformed into pearlite. Due to the slow cooling rate of lost foam casting, carbon atoms may diffuse for a long distance, so that the supersaturated austenite precipitates graphite and transforms into ferrite. This is the main reason why the amount of ferrite in lost foam casting matrix is more than that in clay sand mold casting.