The hatch sand castings are sand castings with overall wall thickness of 2 mm. There is no report on the casting process of sand castings with outline size greater than 667 mm and overall wall thickness of 2 mm in China. The sand casting adopts counter gravity casting, which is characterized by filling and solidification of liquid metal under pressure, controlling the filling speed of liquid alloy and effectively improving the filling capacity of liquid alloy; The alloy solidifies under pressure to effectively improve the internal quality of sand castings.

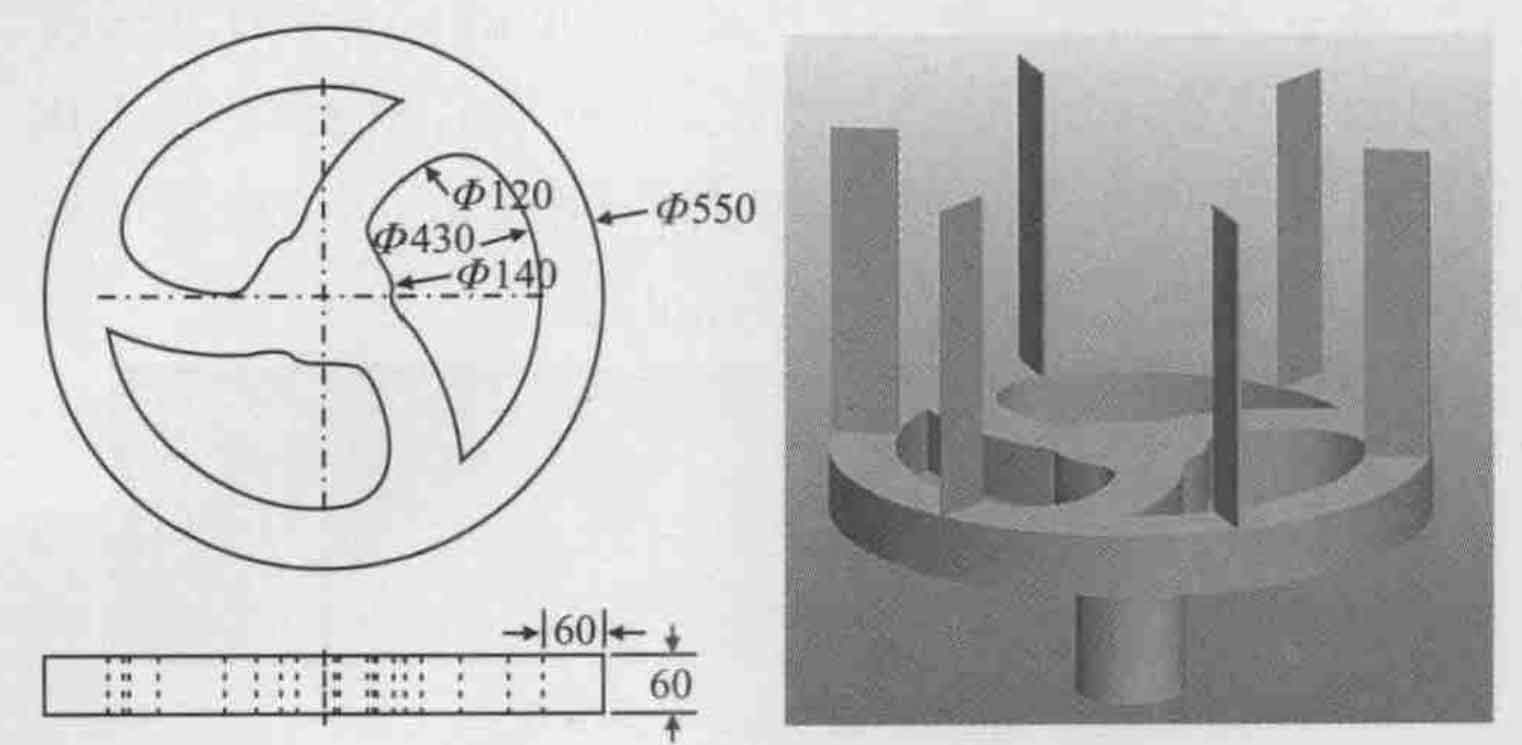

In order to reduce the risk, cost and development time, the mold filling simulation test of thin-wall specimen of counter gravity sand casting was carried out at the beginning of the process design of hatch sand casting. In the test, the same sand mold adopts different counter gravity casting methods, Six 2 mm thin-walled samples (Fig. 1) were cast at one time, and the comparative tests of pressure regulating sand casting, low-pressure sand casting and differential pressure sand casting were carried out. The mold filling capacity was judged according to the sample length, the samples were flaw detected, and the effects of different sand casting methods on the internal quality of the samples were preliminarily investigated. In order to ensure the effectiveness of the comparative test, the test conditions were consistent.

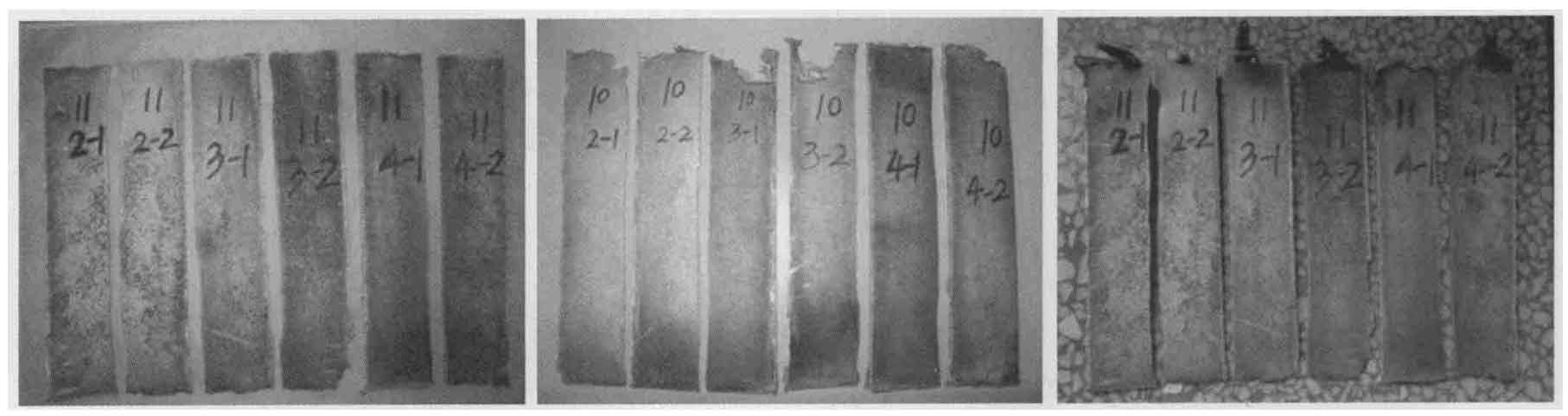

The test results of pressure regulating sand casting, low pressure sand casting and differential pressure sand casting are shown in Figure 2. It can be seen from Figure 2 that under the pouring conditions of 750 ℃ pouring temperature, 100 mm / s mold filling speed and 400 s pressure holding time, the filling capacity of pressure regulating sand casting process is equivalent to that of low-pressure sand casting process, while the filling capacity of differential pressure sand casting process is poor, but its filling capacity can also meet the needs under the condition of reasonable exhaust structure.

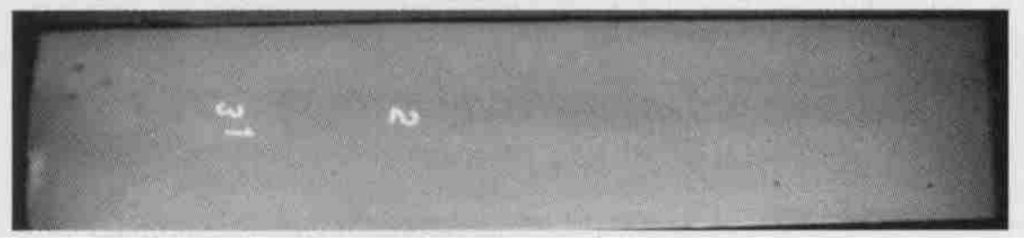

Figure 3 shows the X-ray flaw detection negative film of the test piece under different sand mold casting process conditions. From the X-ray results, under the three sand mold casting conditions of pressure regulation, low pressure and differential pressure, the internal quality of thin-walled sand mold casting shows different sand mold casting defects. Under the condition of pressure regulating sand mold casting, pinhole defects are more prominent; Under the conditions of low-pressure sand mold casting and differential pressure sand mold casting, it mainly shows loose defects, but the loose defect grade of differential pressure sand mold casting process is lighter than that of low-pressure casting process. This is mainly because: under the condition of pressure regulating sand casting with vacuum of – 90 kPa, the liquid metal at the lower end of the riser can provide effective feeding for solidification shrinkage during solidification, and the test piece is not loose, but the aluminum alloy liquid is very easy to precipitate hydrogen during solidification, and pinholes are still formed even for 2 mm thin pieces, so pinhole defects are more prominent during pressure regulating sand casting; Under the condition of low pressure sand casting, the gas pressure is an atmospheric pressure. Due to the rapid solidification of thin-wall sand casting, compared with pressure regulating sand casting, hydrogen is not easy to precipitate; Under the condition of differential pressure sand casting, the thin-walled specimen solidifies under the pressure environment of 500 kPa, and hydrogen is very difficult to precipitate, so there are basically no pinhole defects. Because there is no feeding channel for the thin-wall specimen under the test conditions, there are porosity defects in low-pressure sand casting and differential pressure sand casting.

From the above simulation test results, it can be seen that under the conditions of pressure regulation, differential pressure and low-pressure sand mold casting, if reasonable pouring parameters and reasonable exhaust structure are set, the mold filling capacity can meet the requirements; In terms of internal quality, due to the particularity of pressure regulating sand casting process, pinhole defects are difficult to avoid and can not meet the internal quality requirements of hatch sand casting; Although shrinkage porosity defects also appear in differential pressure sand casting and low pressure sand casting processes, the internal quality of sand castings can be improved by setting reasonable gating system, riser feeding and cold iron chilling system in the subsequent development of sand castings. Therefore, differential pressure sand casting and low-pressure sand casting are preferable sand casting processes, but the mechanical properties of hatch sand casting body are very high. In order to study the influence of low pressure and differential pressure sand casting process on the mechanical properties of thin-walled parts, a reasonable pouring and feeding system of thin-walled parts was designed. D357 alloy was used for pouring. X-ray flaw detection of thin-walled parts showed that there were no defects in the test pieces.

It is found from the data that it is difficult to meet the standard requirements of body mechanics by using low-pressure sand casting process. Compared with low-pressure sand casting, sand castings solidify under high pressure environment under differential pressure sand casting process, which speeds up the solidification speed of sand castings and improves the body mechanical properties of sand castings, Thus, it can ensure that the mechanical properties of sand casting body can meet the requirements of relevant standards. Through the comprehensive analysis of the above test results, the differential pressure sand casting process scheme is adopted to trial produce the hatch sand casting.

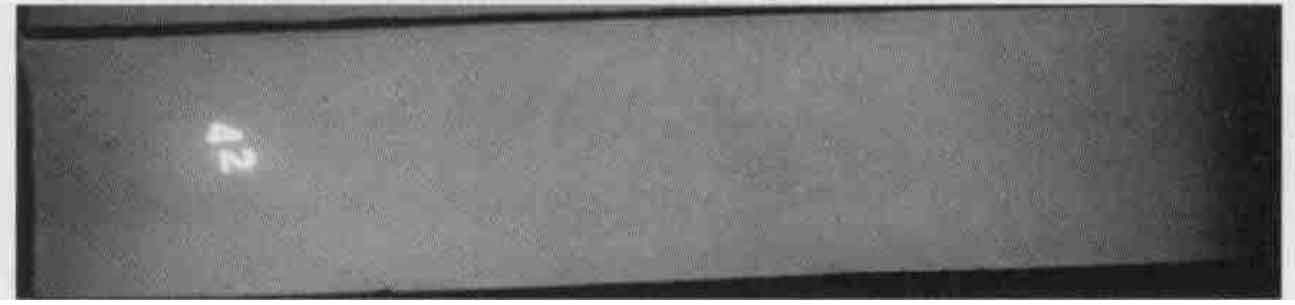

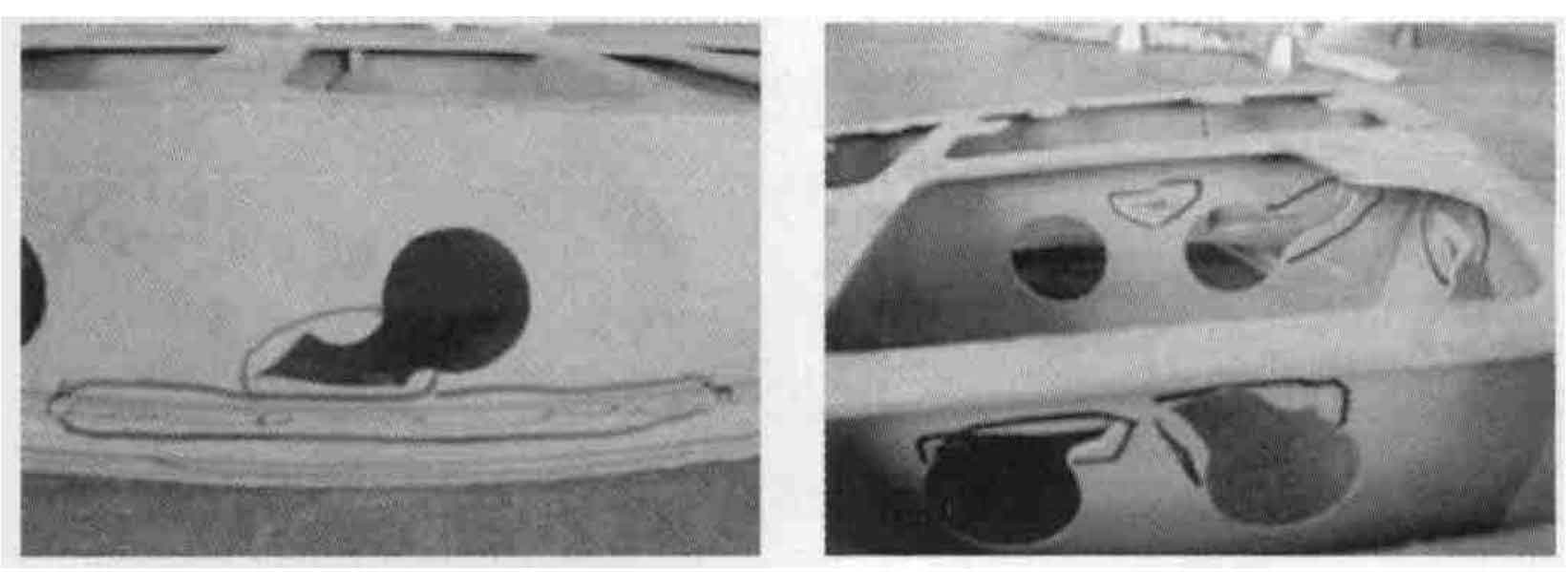

At the initial stage of the study, the sand mold castings of the hatch were poured under the pouring conditions of the alloy liquid, the pouring temperature of 745 ℃± 5 ℃, the mold filling speed of 100 mm / s, the synchronous pressure of – 90 kPa and the pressure holding time of 400 s. According to the inspection results of the cast sand castings, it is found that the sand castings are not filled locally, as shown in Fig. 4.

Through analysis, it is considered that the heat loss of thin-walled sand castings is large and the filling capacity decreases sharply in the filling process. In order to improve the mold filling ability of sand casting, the close arranged cylindrical runner is proposed in the process design, so that the heat near the inner gate is dispersed and evenly distributed, the mold filling is stable, which is conducive to mold filling and shrinkage, and ensure the integrity of mold filling in sand casting; At the same time, the pouring temperature of the alloy liquid shall be increased to 750 ℃± 5 ℃, the mold filling speed shall be increased to 120 mm / s, a layer of thermal insulation coating shall be applied on the surface of the sand mold, and the exhaust of the sand mold shall be strengthened. After the improvement, the pouring sand mold casting is completely filled.