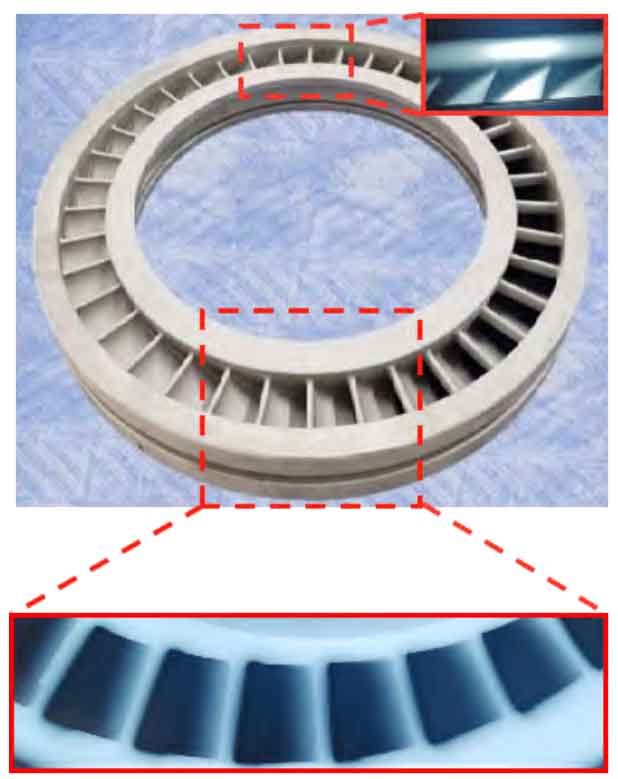

As shown in the figure, the finished product of the investment casting of the turbine guide poured by this gating system is subject to X-ray nondestructive testing of the investment casting of the turbine guide using an X-ray flaw detector.

It can be seen from the figure that there are no holes or loose defects in the investment casting of the turbine guide, and the internal quality of the blade also meets the process requirements of the turbine guide casting.

Compared with the defect simulation results, there is no large deviation between the two, and the coincidence is good.

Therefore, the actual test results have better verified the accuracy and certification ability of ProCAST process simulation, and have certain practical guidance.