Steel castings are widely used in mining machinery, transportation, locomotive traction, lifting machinery, and wind power fields. Due to its wide applicability and low production cost, sand casting is still used in the production of many steel castings.

Zheng Baotang simulated the steel casting process plan for the hook body of the 17 type railway freight car well, with casting process parameters: pouring temperature of 1580 ℃, pouring speed of 75cm/s when filling for 30 seconds. Han Bao et al. optimized the casting process of wheel axle steel castings and conducted numerical simulation. The research results showed that the pouring temperature was 1570 ℃ and the pouring speed was 10kg/s. Liu Chen et al. optimized the sand mold casting process for crossbeam steel castings using computer simulation. At a pouring temperature of 1550 ℃, the yield of the process was 72%.

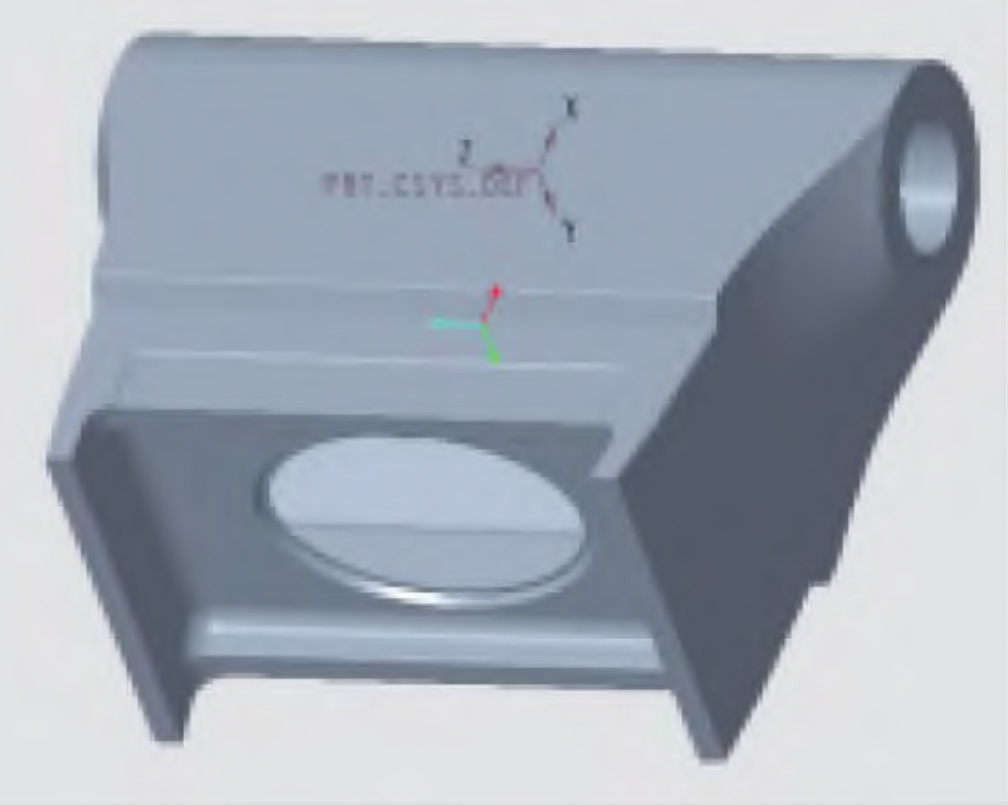

The machining allowance of sand casting shell steel castings is large, and defects such as pores, inclusions, insufficient pouring, shrinkage and porosity are prone to occur during the production process, resulting in a low qualification rate of castings. The influence of casting process parameters on the pore volume size of steel shell castings is simulated using ProCAST software, providing theoretical guidance for the sand casting process design of steel shell castings, thereby reducing the workload of experiments, reducing the trial production cycle and cost of castings, Reduce casting defects, improve casting quality and economic benefits.