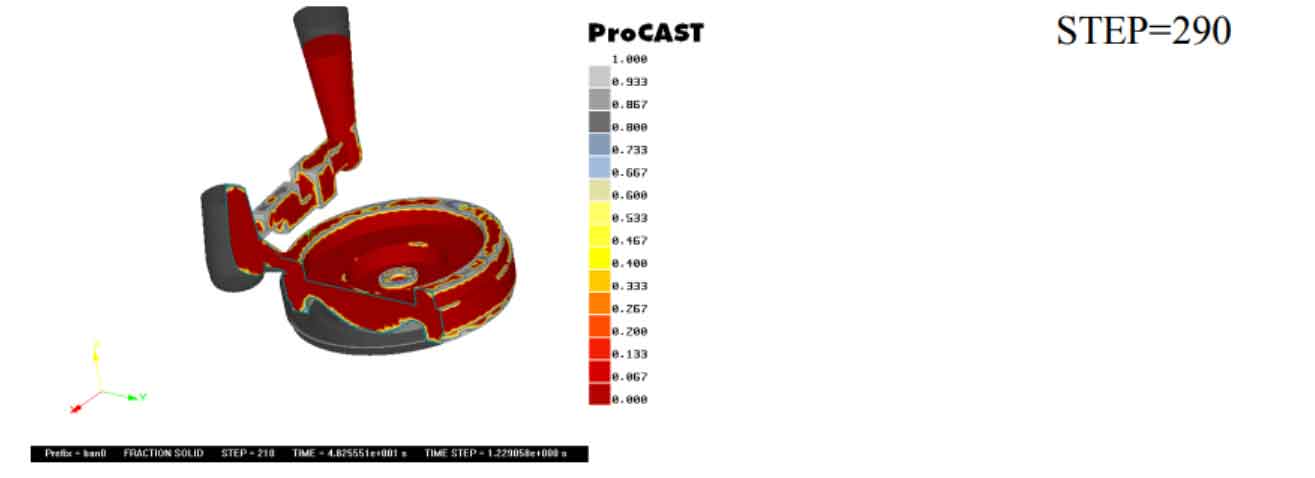

First of all, it is necessary to conduct solid modeling and mesh division, and then set parameters. This is the same as the first scheme, but it only adds the setting of chill iron. Therefore, the pretreatment process of sand casting simulation is the same as the original process scheme. The filling analysis process is not detailed. Here, it is only displayed in the solidification process. When STEP=120, the sand casting starts to solidify. The simulation analysis process is as follows:

From the solidification process, it can be seen that during the solidification process of sand castings, the feeding channel is basically in a smooth state, and the residual liquid is transferred to the external riser of the flywheel, which can effectively feed the sand castings.