At present, the nut of testing machine produced by our company is easy to produce shrinkage cavity and porosity defects, and the reject rate is more than 60%, but the yield is low. Based on this situation, process improvement is required.

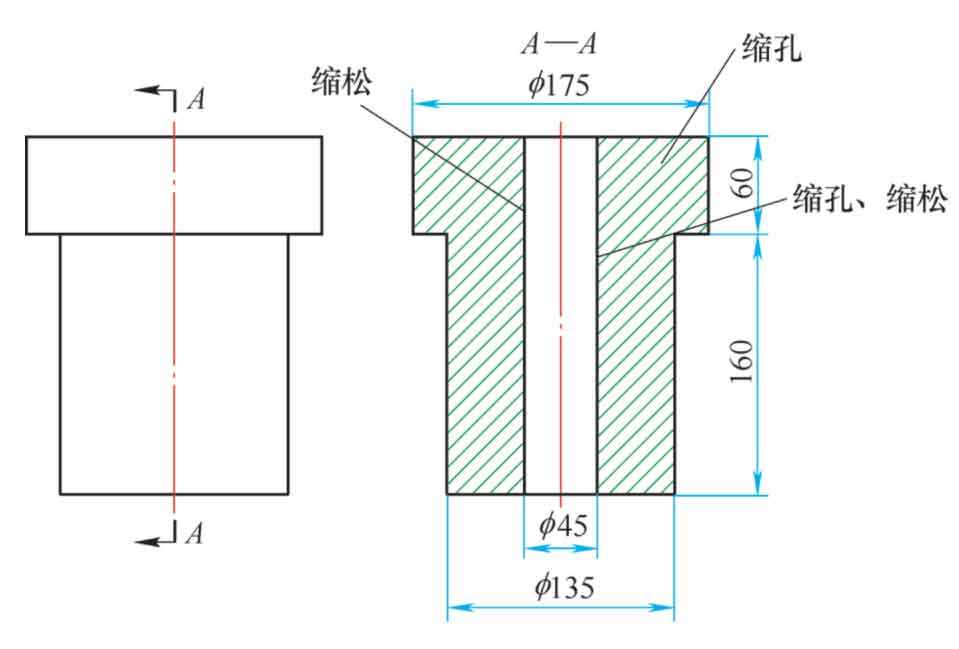

The screw nut belongs to medium wall thickness castings, most of which have a wall thickness of 45mm, some have a wall thickness of 65mm, the material is QT600-3, the blank weight is 25kg, and the overall dimension is φ 175mm × 220mm。 The casting shall have no casting defects such as shrinkage porosity, shrinkage cavity, inclusion and air hole, and no defects are allowed in the screw nut hole. The structure of the nut casting is shown in the figure.

The main defects of the screw nut casting are shrinkage defects such as shrinkage porosity and shrinkage cavity, which are mainly located in the middle of the hole and below the middle of the upper surface (see figure). Casting shrinkage includes three stages: liquid shrinkage, solidification shrinkage and solid shrinkage. Liquid shrinkage affects the size of shrinkage cavity, solidification shrinkage affects the tendency of shrinkage porosity, and solid shrinkage affects the final contour size. The solid shrinkage problem can be solved by taking 1%~1.3% scale in the process of making the pattern, so the shrinkage defect can be analyzed and solved from the aspects of liquid shrinkage and solidification shrinkage.

As the Nut screw casting is made of ductile iron, its solidification feature is “paste” solidification, that is, when the austenite surrounding the graphite is close to contact, the molten iron is divided into discontinuous molten pool, at this time, the molten iron can no longer flow, and the feeding channel is lost, presenting a paste. In the solidification process, when the eutectic temperature is reached, most liquids begin to solidify at the same time, and the precipitation of graphite causes volume expansion and pressure increase.

To sum up, this paper analyzes and improves the original process from two aspects of liquid shrinkage and solidification shrinkage and related influencing factors, combined with the solidification characteristics of ductile iron. Through the improvement of the casting process, the quality of the screw nut castings and similar products met the requirements, and the process yield was increased. Compared with that before the improvement, the scrap rate was significantly reduced to less than 5%, which not only guaranteed the casting quality, improved the production efficiency, but also guaranteed the production cycle of the products.