1. Introduction

In the industrial landscape, ball mills play a pivotal role across diverse sectors such as mineral processing, building materials, and power generation. The liner, a core component of the ball mill, serves as a crucial safeguard. Its primary function is to shield the ball mill’s cylinder from the impact and abrasion inflicted by grinding media and materials. This protection not only extends the lifespan of the ball mill but also ensures its stable and reliable operation. High manganese steel is a commonly used material for ball mill liners due to its excellent combination of plasticity, toughness, and work – hardening properties. However, it is plagued by a high shrinkage rate and low thermal conductivity, which makes it prone to shrinkage holes and porosity during the casting process.

Lost foam casting has emerged as a popular casting method in recent years, offering advantages like high design flexibility, precise casting dimensions, cost – effectiveness, and reduced environmental impact. Nevertheless, due to its unique casting mechanism relying on negative pressure for pouring and solidification, traditional gravity casting theories and experiences cannot be directly applied. To address these challenges and optimize the lost foam casting process for high manganese steel liners, this study utilizes ProCAST finite – element software. By simulating different casting processes, it aims to analyze the filling and solidification behavior of the liners, predict casting defects, and ultimately identify the optimal casting process.

2. The Role of Ball Mill Liners and the Significance of Optimization

2.1 Function and Importance of Ball Mill Liners

Ball mill liners are integral to the proper functioning of ball mills. They act as a buffer between the grinding media (such as steel balls) and the inner surface of the ball mill cylinder. During the grinding process, the liners endure continuous impacts from the grinding media as they cascade and roll within the mill. Additionally, they resist abrasion caused by the movement of the materials being ground. Table 1 summarizes the key functions and their significance.

| Function | Significance |

|---|---|

| Impact Resistance | Protects the ball mill cylinder from damage due to the high – energy impacts of grinding media, preventing cracks and deformation. This ensures the structural integrity of the ball mill and reduces the frequency of cylinder replacements, thus minimizing downtime and maintenance costs. |

| Abrasion Resistance | Reduces wear on the cylinder surface, extending the service life of the ball mill. A longer – lasting liner means less frequent liner replacements, which is cost – effective in terms of both material and labor. It also helps maintain the consistent performance of the ball mill over time. |

| Influence on Grinding Efficiency | The shape and design of the liners can affect the movement of the grinding media and materials inside the mill. Well – designed liners can enhance the grinding efficiency by promoting better mixing and impact distribution, leading to more efficient material comminution. |

2.2 High Manganese Steel as a Liner Material

High manganese steel, especially ZGMn13, is widely chosen for ball mill liners. After undergoing water – toughening treatment, it forms a single austenite structure. The manganese in the steel acts as an austenite – stabilizing element, effectively suppressing the formation of carbides at the grain boundaries. This results in excellent plasticity and toughness of the material. When subjected to intense impact or extrusion during the ball – milling operation, the surface of the high – manganese – steel liner rapidly hardens through work – hardening, while the core retains its good plasticity and toughness. This unique property combination makes it highly suitable for the harsh working conditions of ball mill liners. However, its high shrinkage rate and low thermal conductivity pose challenges during the casting process, increasing the likelihood of shrinkage – related defects. Table 2 shows the chemical composition of ZGMn13 high manganese steel.

| Element | Content (%) |

|---|---|

| C | 1.40 |

| S | 0.005 |

| Mn | 13.35 |

| P | 0.038 |

| Si | 0.70 |

| Cr | 2.10 |

| Ni | 0.03 |

| V | 0.025 |

| Al | 0.005 |

| Fe | Balance |

2.3 Challenges in High Manganese Steel Liner Casting

The casting of high manganese steel liners is fraught with difficulties mainly due to its material characteristics. The high shrinkage rate means that during solidification, the metal undergoes significant volume changes. When the shrinkage is not properly compensated, shrinkage holes and porosity can form. The low thermal conductivity of high manganese steel leads to uneven heat dissipation during solidification. This can cause temperature gradients within the casting, resulting in non – uniform solidification and the formation of hot spots, which are prone to shrinkage defects. In addition, high manganese steel has a tendency to solidify in a mushy state, further complicating the feeding of molten metal to compensate for shrinkage.

3. Lost Foam Casting Process: Principles and Advantages

3.1 Process Principles

Lost foam casting is a near – net – shape casting process. It involves creating a pattern made of expandable polystyrene (EPS) or other similar foam materials. The pattern is coated with a refractory coating and placed in a sand mold. Once the mold is filled with sand, the molten metal is poured into the mold. As the molten metal enters, it heats and vaporizes the foam pattern, gradually replacing it. The negative pressure applied during the process helps to evacuate the gases generated from the vaporization of the foam and promotes the smooth filling of the molten metal into the mold cavity.

3.2 Advantages over Traditional Casting Methods

Compared to traditional casting methods such as sand casting and investment casting, lost foam casting offers several distinct advantages. Table 3 lists and compares these advantages.

| Advantage | Explanation | Traditional Casting Comparison |

|---|---|---|

| Design Flexibility | Allows for complex geometries without the need for extensive core – making. Intricate shapes can be easily achieved with the foam pattern, reducing design constraints. | In sand casting, complex cores are often required for complex shapes, increasing the complexity and cost of the casting process. Investment casting also has limitations in terms of shape complexity and production volume. |

| High – Dimensional Accuracy | Provides high – precision casting dimensions. The foam pattern has a stable shape, and the negative – pressure filling process helps to ensure consistent mold filling, resulting in less dimensional variation. | Traditional sand casting may experience significant dimensional errors due to factors like mold expansion and contraction. Investment casting can be precise but is often more expensive for large – scale production. |

| Cost – Effectiveness | Reduces production costs in the long run. It eliminates the need for some costly operations such as core – making and mold assembly in traditional casting. The use of a single – piece foam pattern simplifies the production process. | Sand casting requires multiple steps for core – making and mold assembly, which increases labor and material costs. Investment casting is relatively expensive due to the use of expensive materials and complex processes. |

| Environmental Friendliness | Generates less waste and pollution. The foam pattern is fully consumed during the casting process, and there is no need for chemical binders in large quantities as in some traditional casting methods. | Traditional sand casting often produces a large amount of waste sand, and some casting methods use chemical binders that can be environmentally harmful. |

4. Finite Element Simulation with ProCAST: Methodology

4.1 Selection of ProCAST Software

ProCAST is a powerful finite – element software widely used in the casting industry for simulating casting processes. It can accurately predict the filling and solidification behavior of molten metal, as well as the formation of casting defects. ProCAST offers a comprehensive set of modules for material property definition, mesh generation, and process parameter setting. Its ability to handle complex geometries and non – linear heat transfer makes it an ideal choice for simulating the lost foam casting process of high manganese steel liners.

4.2 Three – Dimensional Model Creation and Parameter Setting

4.2.1 Casting Dimensions and Process Design

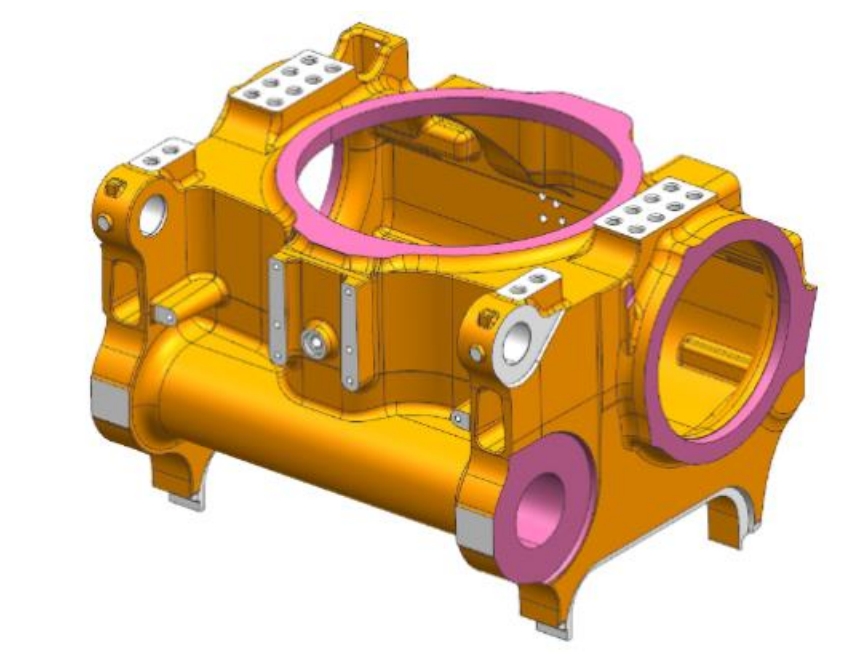

The high manganese steel liner is approximated as a cuboid with specific dimensions. The large – plane size is approximately 590 mm×340 mm, and the working surface has a single – peak large – wave shape, with a maximum thickness of 120 mm and a minimum thickness of 80 mm. There are also through – holes in the thickest part and on the working surface. To ensure smooth filling of the molten metal, three lost foam casting processes were designed:

- Process A: Top – gating casting, with 8 liners cast in one batch. No riser is used for this process.

- Process B: Step – side gating casting, capable of casting 10 liners in one batch, also without a riser.

- Process C: Side – gating casting, with 4 liners cast in one batch, and a riser is included for better feeding during solidification.

4.2.2 Thermal Physical Parameter Definition

The material of the casting is ZGMn13 high manganese steel. Its thermal physical properties, such as density, enthalpy, thermal conductivity, and solid – phase fraction as a function of temperature, were calculated using the Database module in ProCAST. The cooling rate was set to 5 °C/s. The EPS foam used for the pattern has a density of 25 kg/m³, a specific heat capacity of 3.7 kJ/(kg·K), a latent heat of 100 kJ/kg, and a thermal conductivity of 0.15 W/(m·K). The resin sand used for the mold has a density of 1520 kg/m³, a specific heat capacity of 1.22 kJ/(kg·K), and a thermal conductivity of 0.53 W/(m·K). The permeability of the resin sand was set to 1e – 7 to ensure proper gas escape during the casting process. Table 4 summarizes the key thermal physical parameters.

| Material | Density (kg/m³) | Specific Heat Capacity (kJ/(kg·K)) | Thermal Conductivity (W/(m·K)) | Other Key Parameters |

|---|---|---|---|---|

| ZGMn13 Steel | Calculated as a function of temperature (see Figure 2 for details) | Calculated as a function of temperature | Calculated as a function of temperature | Solid – phase fraction as a function of temperature (see Figure 2) |

| EPS Foam | 25 | 3.7 | 0.15 | Latent heat: 100 kJ/kg, Vaporization temperature range: 330 – 350 °C |

| Resin Sand | 1520 | 1.22 | 0.53 | Permeability: 1e – 7 |

4.2.3 Mesh Generation

The three – dimensional CAD models of the liners and the casting systems were imported into ProCAST. In the Visual – Mesh module, the models were meshed. The minimum mesh size, set to 5 mm, was located near the grooves of the liners to accurately capture the details of the geometry. The maximum mesh size, 100 mm, was used at the sand – box area. After meshing, Process A had 1,352,871 tetrahedral meshes, Process B had 1,575,216 tetrahedral meshes, and Process C had 1,181,657 tetrahedral meshes. Figure 3 shows the meshed models for each process.

[Insert Figure 3: Meshed models for Process A, Process B, and Process C]

4.2.4 Process Parameter Setting

In the Visual – Cast module, various process parameters were defined. The pouring temperature was set to 1420 °C, and the pouring speed was 20 kg/s. The initial temperature of the resin sand and the EPS foam pattern was 20 °C, and the ambient temperature was also 20 °C. The heat – transfer coefficients at the interfaces were set as follows: 20 W/(m²·K) between the EPS foam and the resin sand, and 50 W/(m²·K) between the molten metal and the resin sand. The outer surface of the resin sand was set for air cooling, and the negative pressure during the casting process was controlled at 0.045 MPa.

4.2.5 Simplification of Heat Transfer at the Interface during the Filling Process

During the filling process of lost foam casting, the molten metal burns and vaporizes the EPS foam pattern. There is a complex heat – transfer process between the molten – metal front and the foam. In ProCAST, the heat – transfer coefficient between the molten metal and the foam is adjusted based on their distance. When the distance is 10 mm, the heat – transfer coefficient is approximately 20 W/(m²·K), and when they are in contact, it reaches approximately 250 W/(m²·K).

4.3 Prediction Criteria for Shrinkage Holes and Porosity

4.3.1 POROS Criterion

The POROS criterion is a built – in solidification – defect prediction criterion in ProCAST. When the casting solidifies, the edges of the casting solidify first, forming a solid shell. This can prevent the feeding of molten metal to the interior, creating isolated liquid – phase regions. For most alloys, as the temperature decreases, the density increases. When the molten metal in an isolated region cools, shrinkage holes may form. In practical calculations, if the POROS value exceeds 1%, shrinkage holes are considered to be present.

4.3.2 Niyama Criterion

The Niyama criterion is widely used to predict micro – porosity between dendrites. It uses the ratio of the temperature gradient (G) at the end of solidification to the square root of the cooling rate (R), i.e., G/√R. When G/√R is less than a certain critical value, shrinkage holes and porosity are likely to occur in that region. The smaller the value of G/√R, the higher the tendency for shrinkage – related defects. This critical value is independent of the shape and size of the casting within the studied range.

5. Simulation Results and Analysis

5.1 Filling Process Analysis

5.1.1 Process A

The filling process of Process A was simulated. At 11.95 s (when 30% of the filling was complete), the molten metal began to enter the interior of the liner castings. However, the filling amounts of the 8 liners were not uniform, with the 2 liners closer to the sprue being filled more. At 29.62 s, 70% of the filling was completed. During the filling process, due to the complex heat – transfer between the molten – metal front and the foam pattern, the foam rapidly vaporized, and the generated gas could not be exhausted in time. This created a gas gap between the molten metal and the pattern, and the gas pressure in the gap hindered the filling of the molten metal. As a result, the molten – metal flow became disordered in 3 liners at 44.90 s (when 90% of the filling was completed), and the last – filled parts were the bottoms of 4 liners. Figure 4 shows the filling process of Process A at different stages.

5.1.2 Process B

For Process B, at 14.95 s (30% filling), the molten metal entered the liner castings in a step – by – step manner from the side. At 35.81 s (90% filling), due to the formation of the gas gap, the filling ability of the molten metal was significantly reduced, and the filling processes of two liners became severely disordered. These two liners were also the last to be filled. Figure 5 shows the filling process of Process B at different stages.

5.1.3 Process C

In Process C, the molten metal started to enter the liner castings from the side at 6.94 s (30% filling). By 21.53 s (70% filling), the molten – metal flow in the model was stable. At 27.72 s (90% filling), the last – filled part was the bottom of the liner far from the gate. Since the number of simultaneously cast liners was relatively small, the generated gas could be quickly discharged from the foam pattern, and no turbulent flow occurred during the filling process. Figure 6 shows the filling process of Process C at different stages.

5.1.4 Comparison of Filling Processes

A comparison of the filling processes of the three processes is presented in Table 5. It can be seen that both Process A and Process B experienced disordered molten – metal flow, which was likely caused by the complex heat – transfer with the foam pattern and the gas generated during foam decomposition. Process C, on the other hand, had a smooth filling process.

| Process | Filling Start Time | Filling Completion Time (90%) | Flow Condition | Reasons for Flow Disorder (if any) |

|---|---|---|---|---|

| A | 11.95 s | 44.90 s | Disordered | Heat – transfer with foam pattern and gas from foam decomposition |

| B | 14.95 s | 35.81 s | More disordered | Heat – transfer with foam pattern and gas from foam decomposition |

| C | 6.94 s | 27.72 s | Smooth | Less gas generation due to fewer castings, allowing for quick gas discharge |

The temperature field distribution of the liners at the end of the filling process was also analyzed. Process A had a relatively uniform temperature field, with the last – filled 4 liners having slightly higher temperatures, but the

5.2 Solidification Process Comparison

To better observe the solidification process of the liner castings, parts of the castings with a solid – phase fraction greater than 70% were hidden. For all three processes, the liners solidified in a sequential manner, starting from the outer edges. In Process A and Process B, without risers, there was no feeding to the central parts. The solidification progressed from the outer edges towards the interior, resulting in hot spots in the core of each liner. In contrast, Process C had a riser, which could feed the central part of the liner during solidification, reducing the likelihood of shrinkage – related defects. However, as solidification continued, hot spots still formed in the core of the castings in Process C. Figures 8 – 10 show the solidification fraction distribution of liners for Process A, Process B, and Process C respectively.

During the solidification process, the temperature distribution of the liner castings for each process was analyzed. For all three processes, the temperature decreased from the interior to the outer edges, meaning the outer edges solidified first. Process A had a relatively small temperature difference across the liner, with the core having the highest temperature. There was also a temperature difference among the 4 liners. Process B had a more significant temperature difference, and the core temperatures of individual liners varied greatly, which might be attributed to the unstable filling process. Process C had a relatively uniform temperature field, with only a small isolated liquid – phase region in the core, resulting in fewer shrinkage – related defects after solidification. Figures 11 – 13 show the temperature field distribution of liners during the solidification process for Process A, Process B, and Process C respectively.

5.3 Solidification Defect Prediction

5.3.1 POROS Criterion Results

The results predicted by the POROS criterion indicated that all liners in the three processes had a tendency for shrinkage holes. In Process A, the last – filled 4 liners had larger shrinkage – pore – prone areas, and the defects were concentrated in the central part of the liners. Process B had severe shrinkage – hole and porosity defects in all liners, with a high probability of surface – related defects in the middle 6 liners. In Process C, the defects were concentrated in the central part of the liners. Figure 14 shows the shrinkage – hole defect prediction results for different casting processes based on the POROS criterion.

[Insert Figure 14: Prediction of cavity defects of liners under different casting processes (POROS criterion)]

5.3.2 Niyama Criterion Results

According to the Niyama criterion, all liners in the three processes were predicted to have shrinkage – hole and porosity defects. In Process A, the defects were concentrated in the core of the castings, and the defects in the middle 4 liners were closer to the surface. In Process B, the middle 6 liners’ surfaces and the inner surfaces of the outer 4 liners had a lower G/√R ratio, indicating a higher probability of shrinkage – related defects. In Process C, a small number of defects were concentrated in the central part of the liners, and no defects were predicted on the surface. Figure 15 shows the shrinkage – porosity defect prediction results for different casting processes based on the Niyama criterion.

[Insert Figure 15: Prediction of shrinkage defects of liners under different casting processes (Niyama criterion)]

5.3.3 Overall Defect Analysis

Overall, all liners in the three casting processes had casting defects. This was mainly due to the shrinkage during solidification, where the liquid – phase and solidification shrinkage of the metal or alloy was greater than the solid – phase shrinkage, and the shrinkage areas did not receive sufficient molten – metal feeding. The temperature – distribution differences in the middle liners led to larger isolated liquid – phase regions, resulting in more shrinkage – related defects. While the defects in the central part of the liners had a relatively minor impact on their performance, the surface defects in Process A and Process B could significantly affect the wear – resistance and mechanical properties of the liners. Therefore, Process C was considered the optimal casting process. Table 6 summarizes the defect characteristics of each process.

| Process | Defect Location | Defect Severity | Impact on Liner Performance |

|---|---|---|---|

| A | Concentrated in the central part, some closer to the surface in middle liners | Moderate in the last – filled 4 liners | Surface defects may reduce wear – resistance and mechanical properties |

| B | Distributed in all liners, with high probability of surface defects in middle 6 liners | Severe | Surface defects have a significant negative impact on wear – resistance and mechanical properties |

| C | Concentrated in the central part | Minor | Minor impact on performance as defects are in the core |

6. Production Verification

Based on the simulation results, Process C was selected for on – site casting. The obtained castings were inspected. As predicted by the simulation, the probability of defects in the core of the castings was high. The castings were cut from the core using a bandsaw, and the cross – section was examined. Figure 16 shows the actual castings and the core cross – section. It was found that the internal defects of the castings produced by Process C were few and concentrated in the core. Some larger defects might be attributed to unstable molten – metal flow during actual filling or non – uniform permeability of the sand. Overall, the defect distribution in the actual production was consistent with the simulation results, validating the effectiveness of the simulation – based process optimization.

7. Conclusion

This study utilized ProCAST software to simulate the filling and solidification processes of three lost – foam casting processes for high – manganese – steel liners used in ball mills. The following conclusions were drawn:

- In the top – gating non – riser process (Process A), the molten – metal filling process was disordered, and after solidification, the shrinkage – hole and porosity defects in the liners were relatively dispersed.

- In the step – side gating non – riser process (Process B), the molten – metal filling process was even more disordered. After cooling and solidification, the liners had more dispersed shrinkage – related defects, and the middle 6 liners had a high tendency for surface shrinkage – hole and porosity defects.

- In the side – gating with – riser process (Process C), the molten – metal filling process was smooth. After solidification, the few shrinkage – hole and porosity defects in the liners were concentrated in the central part. The on – site casting using Process C showed that the actual production defects were consistent with the simulation results.

In summary, Process C is the optimal lost – foam casting process for high – manganese – steel liners, which can effectively reduce casting defects, improve the quality of liners, and provide a reference for the actual production of high – manganese – steel liners in the industry. Future research can focus on further optimizing the process parameters within Process C, such as adjusting the riser size and shape, and exploring the use of different mold materials to further reduce casting defects and enhance the performance of the liners.