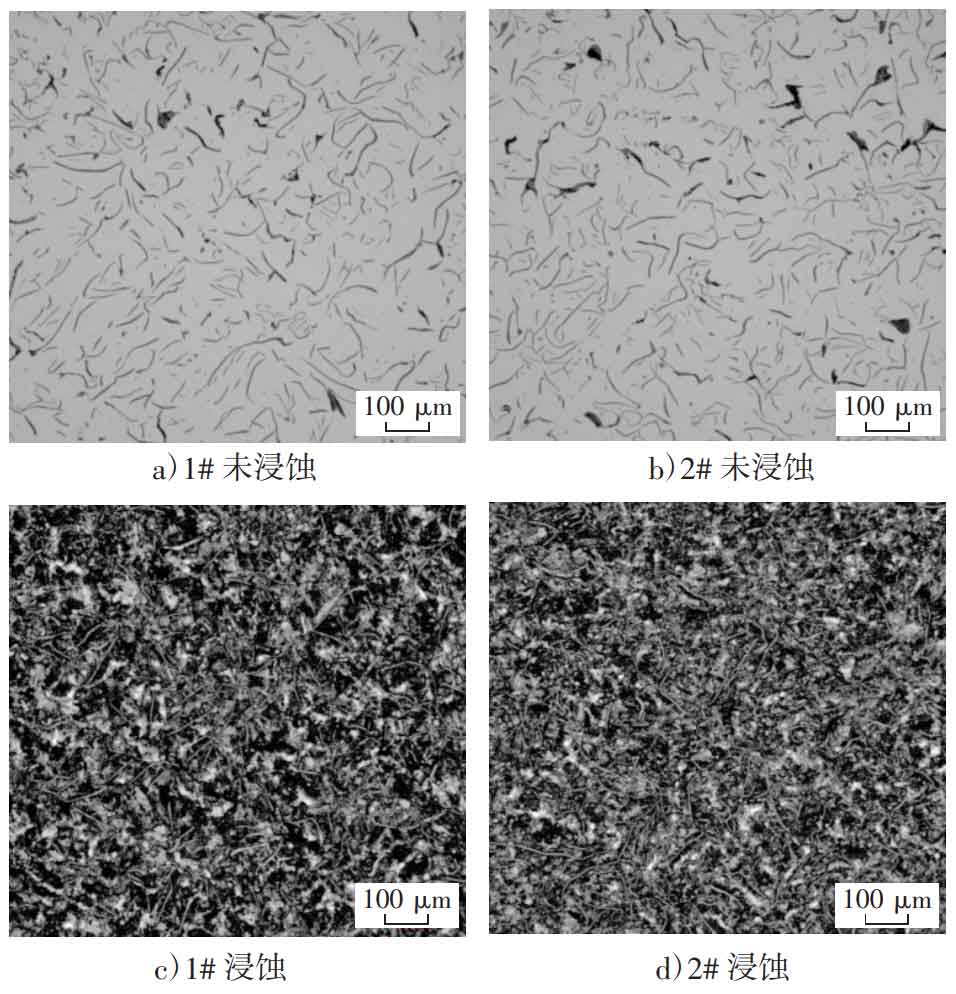

Pour a positioning plate product. The maximum wall thickness of the casting is 90 mm, the minimum wall thickness is 10 mm, and the weight of the casting is about 98 kg Take samples at the wall thickness of 40mm for testing. See Table 1 for the test results of chemical composition, see figure for metallographic structure and table 2 for the test results of mechanical properties

| Serial number | C | Si | Mn | S | Mo | Cr | Ni | Cu | Sb |

| 1# | 3.21 | 1.95 | 0.67 | 0.010 | 0.48 | 0.32 | 0.52 | 0.92 | 0.013 |

| 2# | 3.25 | 1.98 | 0.68 | 0.011 | 0.55 | 0.35 | 0.55 | 0.82 | 0.018 |

It can be seen from the test results that the tensile strength of 1#, 2# two samples is ≥ 300 MPa, the body hardness is ≥ 165 Hb, the rate of type a graphite in the non etched state is > 85%, the mass fraction of pearlite in the matrix after etching with 4% nitric acid alcohol solution is ≥ 98%, and there are no defects in the NDT of the casting, which meets the index requirements of high strength positioning plate.

| Serial number | Type of test block | Tensile strength / MPa | Graphite morphology | Graphite size | Hardness (HB) | Matrix structure |

| 1# | Solid ring drill | 332 | A(>95%) | 4 | 226 | P(98%) |

| 2# | Solid ring drill | 315 | A(>95%) | 4 | 232 | P(98%) |