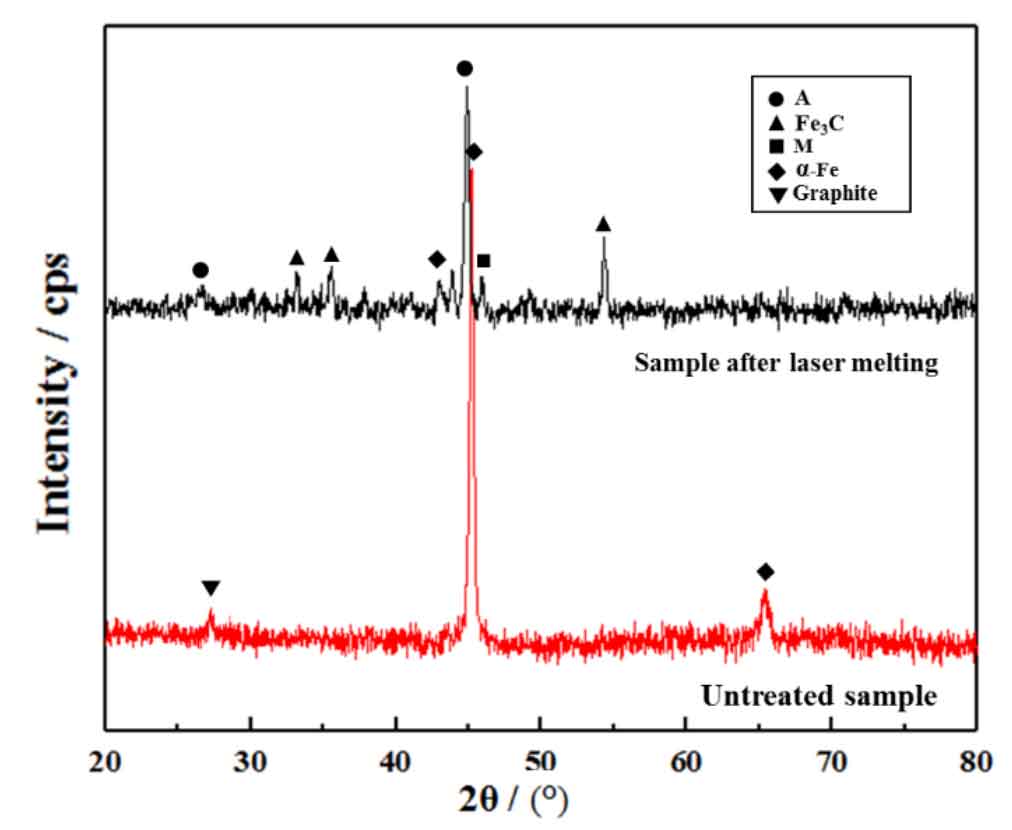

The surface structure of untreated gray cast iron sample is pearlite (P) and graphite (g). From the XRD spectrum of gray cast iron after laser melting in Fig. 1, it can be seen that the phase in the laser melting layer of gray cast iron has changed, the graphite peak on the surface of gray cast iron has disappeared, accompanied by a new diffraction peak. From the diffraction peak calibration results, it can be seen that the microstructure of laser melting layer of gray cast iron is mainly austenite( γ- FE), cementite (Fe3C) and martensite (m). The main components in the laser melting layer of gray cast iron are austenite and cementite. After surface laser melting, pearlite in the laser melting layer of gray cast iron decomposes and body centered cubic ferrite( α- FE) to face centered cubic austenite( γ- FE), the laser melting layer of gray cast iron is completely austenitized. The extremely high temperature in the molten pool increases the power of graphite decomposition, which makes the graphite in the laser melting layer of gray cast iron decompose into carbon atoms and dissolve in austenite. During the rapid cooling process of laser melting layer of gray cast iron, cementite precipitates and grows, martensite structure is formed, and part of austenite has no time to transform to form residual austenite.

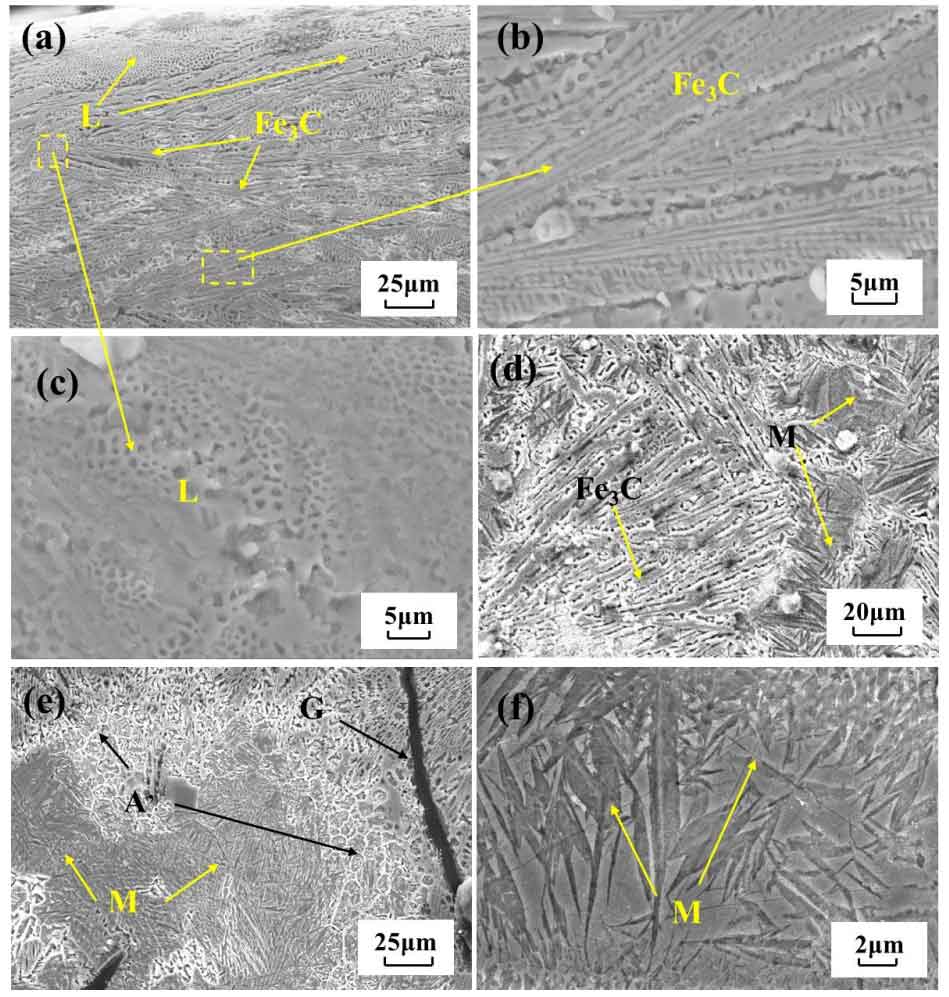

Figure 2 shows the microstructure morphology of the laser melting layer of gray cast iron from the outside to the inside. It can be seen from the figure that the microstructure in the laser melting zone of gray cast iron is basically the same, mainly including coarse dendritic cementite and eutectic ledeburite (cementite and austenite). The cementite in the laser melting layer of gray cast iron is the primary cementite precipitated by eutectic reaction, as shown in Fig. 2 (b), and a continuous network ledeburite structure is distributed between the long strip cementite, as shown in Fig. 2 (c). In the laser melting zone of gray cast iron, cementite grows along the direction of heat flow. Due to the different heat dissipation directions of heat flow on the surface of molten pool, the growth direction of cementite is chaotic. Therefore, there is no obvious directional distribution of Cementite on the surface of laser melting zone of gray cast iron. Figure 2 (d) and (E) show the microstructure of the heat affected zone. There are three obvious structures in the heat affected zone. The laser melting zone near the gray cast iron is mainly composed of cementite, and the part near the matrix is mainly composed of lamellar martensite and retained austenite. Due to the low temperature in the heat affected zone and the heat transfer of the matrix, the cooling rate of the heat affected zone is very fast, which makes the austenite structure change into martensite. Due to the partial decomposition of graphite in the heat affected zone, the carbon content in the austenite formed in the heat affected zone is less, which provides conditions for the transformation of austenite to martensite in gray cast iron. Part of austenite is too late to transform into martensite to form retained austenite.