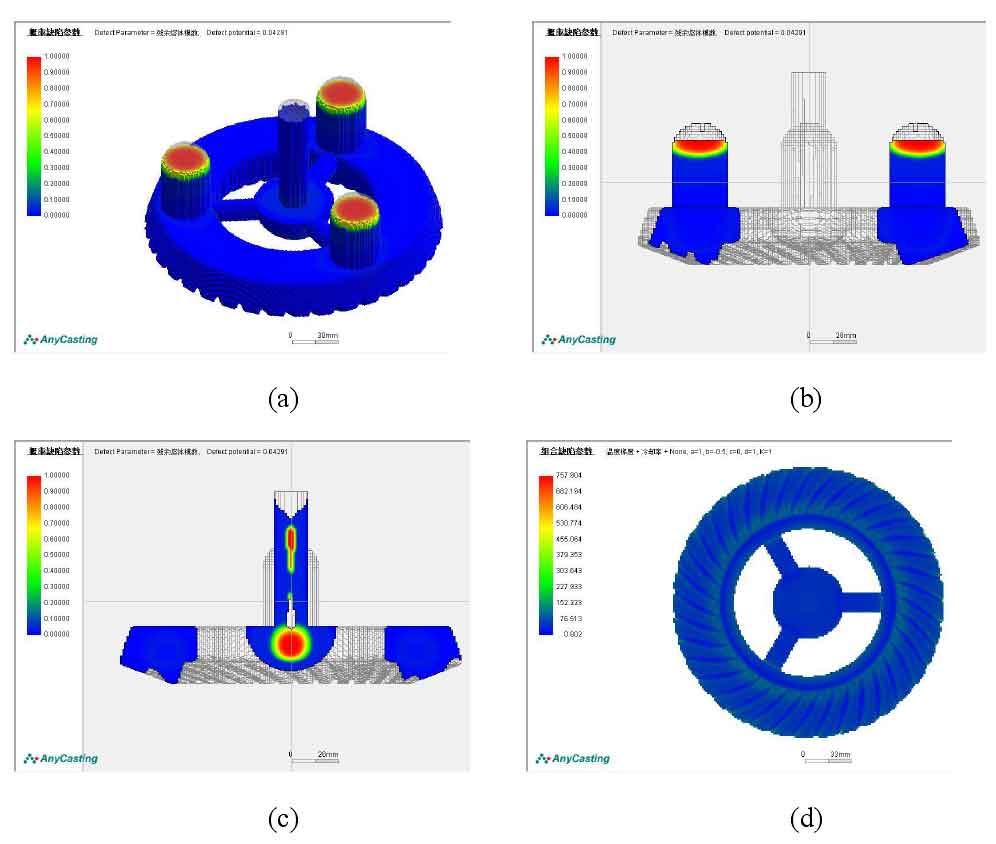

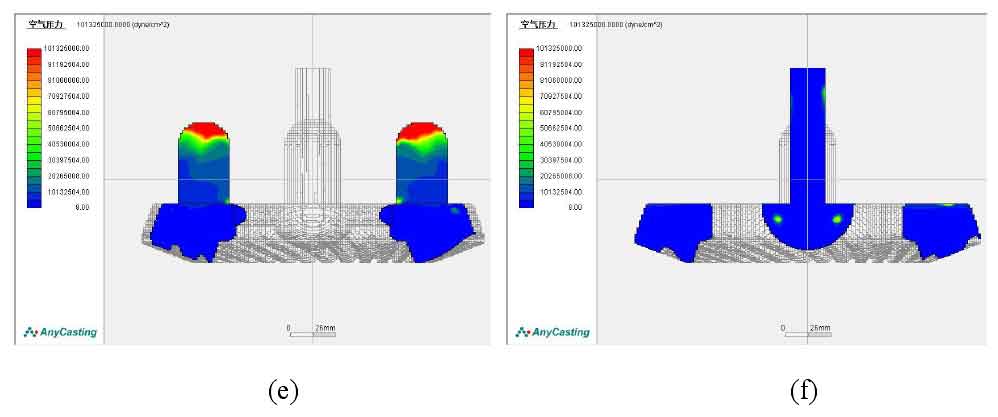

The figure is the schematic diagram of shrinkage defects and air pressure distribution at different positions after complete solidification of gear sand castings.

It can be seen from figures (a) ~ (d) that shrinkage defects are left in the gating system and riser, and there is no obvious shrinkage defect in the main body of sand mold casting; The high forming quality of 1 / 2 teeth of sand mold casting is good, without obvious casting defects, but slight shrinkage defects appear at the edges of the big end and small end of the tooth shape.

Figures (e) and (f) show that there is air pressure distribution inside the riser and on the upper surface of the sand casting; Although the upper surface of sand casting may produce sand casting defects due to residual air, the possible defects can be eliminated by improving pouring temperature and pouring speed or machining.