In recent years, lost foam technology has rapidly developed in China due to its advantages such as low pollution, flexible processing, low labor intensity, and good repeatability, showing significant advantages over other casting processes, especially in the production of box and shell products. In this paper, defects such as burning-on, porosity, and sand wash that are prone to occur in products such as flywheel housing during the lost foam casting process were analyzed. By adjusting the combination process method of the pattern, optimizing the product pouring system, arranging the exhaust and slag discharge risers, and ensuring the rationality of the layout of the inner gate inlet, measures to solve the casting defects of related products are proposed based on the production situation. After the production and machining process, the goal of solving casting defects in the product is achieved.

1. Introduction

Lost foam casting, also known as EPC (Expanded Polystyrene Mould Casting), is a modern casting process characterized by its low pollution, high efficiency, and ability to produce complex shapes. Compared to traditional sand casting, lost foam casting offers more precise dimensions, better repeatability, flexible production, and superior internal quality of castings. Since the patent expired in 1980, lost foam casting technology has developed rapidly worldwide and is now mature both domestically and internationally. Its wide application, particularly in the production of complex shell components, has made it a significant process in the casting industry.

This paper focuses on the application of lost foam casting technology in shell castings and points out the main problems encountered in the production of shell products using this technology. Several casting defects, their causes, and corrective measures are introduced in detail. These defects are mainly manifested during the pouring process, where the foam pattern gasifies and is accompanied by the flow and solidification of molten metal, leading to casting defects such as burning-on, porosity, and sand wash in the production of flywheel housing and similar castings. Taking flywheel housing as an example, this paper discusses the causes and improvement measures for related defects in lost foam casting.

2. Analysis of Casting Defects and Improvement Measures

2.1 Analysis of Burning-On Defects

Burning-on defects occur when molten metal adheres to the molding sand on the casting surface during the pouring process, forming a mixture of sand grains and metal. This is often caused by unreasonable placement, structural design, or process design of the flywheel housing, which prevents the mold cluster from being fully vibrated and compacted within the sand box.

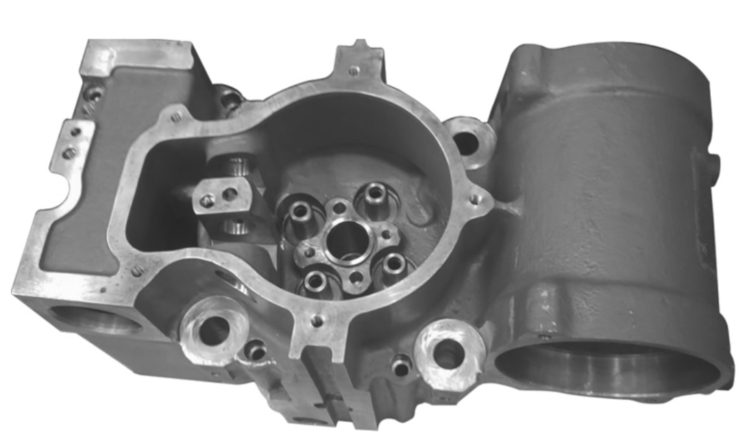

2.1.1 Case Study: 9661 Flywheel Housing

The 9661 flywheel housing, made of HT250 material, weighs approximately 22 kg and has dimensions of 440 mm × 440 mm × 220 mm, with a wall thickness of 5 mm. This product has issues such as a large surface area, thin base wall, and easy deformation. The existing process, as shown in Figure 1, features an inner gate size of 50 mm (length) × 30 mm (height) × 6 mm (width). The molten iron temperature is 14601470°C (melted in an electric furnace), the pouring temperature is 14301440°C, the vacuum degree is -0.025 MPa, and there is no film covering or pressure maintenance. The main defect is sand inclusion in the top inner cavity of the flywheel housing, with a scrap rate of 20%.

The motor hole is located at the bottom in the existing process (Figure 2), and sand inclusion often occurs at the top inner cavity of this product, as shown in Figure 3. This is because the top angle is greater than 90°, and the molding sand cannot be fully compacted during vibration, resulting in loose sand at the top. During the filling of molten metal, local molten metal adheres to the molding sand, causing sand inclusion.

2.1.2 Influencing Factors

The main influencing factors of burning-on defects include the tightness of the molding sand during molding, the refractory degree of the coating, the pouring temperature, and the coating thickness. Except for the top sand inclusion, the rest of the flywheel housing is normal without traces of sand inclusion. Therefore, it is considered to be an issue with the tightness of the molding sand. The analysis indicates two possible reasons: (1) Insufficient molding sand can be filled at the top of the flywheel housing or the existing state of molding sand cannot be vibrated and compacted; (2) The gap between the two flywheel housings is too small, resulting in weak molding sand strength.

2.1.3 Control Measures

To address the mechanism of sand inclusion defects, based on their influencing factors, the following measures are taken for resolution:

- Adjust the placement of the white mold according to the product structure, with the motor hole of the flywheel housing facing upwards to facilitate the filling of molding sand and ensure sufficient molding sand at the top of the flywheel housing.

- Increase the distance between the two flywheel housings from the original 80 mm to 120 mm to ensure sufficient space between the two mold clusters, thereby ensuring the compactness of the molding sand.

2.1.4 Production Verification

After analyzing the causes of the molding sand compactness issue of the flywheel housing and modifying the existing combination process in terms of product placement and combination spacing, production verification was conducted from small batches to large batches under the premise of ensuring unchanged variables such as dipping process, pouring temperature, and vacuum extraction. The result showed zero sand inclusion defects. Through these measures, the goal of completely resolving the sand inclusion defect at the top of the flywheel housing was achieved.

2.2 Analysis of Porosity Defects

When molten metal enters the mold cluster, the white mold gasifies and decomposes, generating a large amount of gas and residues that cannot be timely expelled, resulting in porosity on the casting surface. The occurrence of porosity is related to pouring temperature, coating permeability, pouring speed, etc.

2.2.1 Case Study: SAIC MAXUS Flywheel Housing

The porosity defect in the product is shown in Figure 5. The molten iron temperature is 14601470°C (melted in an electric furnace), the pouring temperature is 14301440°C, the vacuum is -0.025 MPa, and there is no film covering or pressure maintenance. The main defect is porosity at the top motor hole, with a scrap rate of 30%.

The porosity defect appears as smooth holes of various sizes on the casting surface or near the surface after processing, with the hole walls showing an oxidized color. The porosity is mainly concentrated at the top of the product, which is a characteristic manifestation of subsurface porosity.

2.2.2 Influencing Factors

The main influencing factors include:

- Pouring Temperature: When the pouring temperature is low, the foam does not burn completely, and gas is not fully expelled, forming porosity under the skin.

- Local Coating Thickness: Excessive coating thickness at the motor hole prevents gas from being expelled after foam combustion, forming porosity.

- Vacuum Degree: Insufficient vacuum results in gas not being timely extracted, forming porosity.

- Unreasonable Process Design: Lack of exhaust vents at the top of the flywheel housing causes gas to accumulate at the top of the body and not be fully expelled, forming porosity.

2.2.3 Control Measures

To address the mechanism of porosity defects, based on their influencing factors, the following measures are taken for resolution:

- Increase the pouring temperature from 14301440°C to 14501460°C and pour 10 sets.

- Reduce the coating thickness at this location from 2.0 mm to 0.5 mm and pour 10 sets.

- Increase the vacuum degree from -0.025 MPa to -0.045 MPa and pour 10 sets.

- Add a vent piece at the motor hole with dimensions of 50 mm (length) × 30 mm (height) × 5 mm (width) and pour 10 sets.

2.2.4 Production Verification

After analyzing the causes of porosity issues in the flywheel housing and modifying the existing process parameters in terms of pouring temperature, coating thickness, vacuum degree during pouring, and adding vent pieces, production verification was conducted. During the process testing, the controlled variable method was adopted to test with one of the four process parameters changed while the other three remained constant. The results showed that the best outcome was achieved with the fourth scheme (adding a vent piece), with zero porosity defects at the motor hole through subsequent verification from small batches to large batches. The final process is shown in Figure 6.

2.3 Analysis of Sand Wash Defects

Sand wash defects occur when the mold cluster pouring system, including the sprue, runner, and inner gate, is not completely sealed, especially the sprue, which can easily form a siphon effect, leading to sand wash defects. Unreasonable design of the pouring system for the product, unsmooth filling,Moreover, the integration of technology into various industries has significantly transformed business operations. For instance, in the healthcare sector, electronic health records (EHRs) have replaced traditional paper charts, enabling healthcare professionals to access patient information more efficiently and securely. This digitization not only improves patient care but also facilitates research and quality improvement initiatives. Similarly, in the retail industry, e-commerce platforms have revolutionized how consumers shop, offering convenience, a wide range of products, and competitive pricing. These platforms utilize data analytics to personalize shopping experiences, predict consumer behavior, and optimize inventory management.

Furthermore, advancements in artificial intelligence (AI) and machine learning are driving innovation across multiple domains. In finance, AI algorithms are used for fraud detection, algorithmic trading, and credit scoring, enhancing the accuracy and speed of financial decisions. In education, AI-powered tutoring systems and personalized learning platforms cater to individual student needs, improving learning outcomes and making education more accessible. Additionally, AI is playing a pivotal role in smart city development, where it optimizes traffic flow, enhances public safety, and improves resource management through data analysis and predictive modeling.

The impact of these technological advancements extends to our daily lives as well. Smartphones, equipped with advanced sensors and connectivity, have become indispensable tools for communication, navigation, entertainment, and even managing personal finances. The Internet of Things (IoT) has interconnected devices in our homes, offices, and cities, creating ecosystems that are more efficient, responsive, and sustainable. From smart thermostats that regulate home heating and cooling to wearable fitness devices that monitor health metrics, IoT technology is enhancing our quality of life.

However, the rapid pace of technological change also presents challenges. Cybersecurity threats are becoming increasingly sophisticated, necessitating robust defenses and continuous vigilance. The digital divide, where access to technology is unequal, risks exacerbating social and economic inequalities. Moreover, the ethical implications of AI and other emerging technologies, such as privacy concerns and potential biases in decision-making algorithms, require careful consideration and regulation.

In conclusion, the evolution of technology has been transformative, driving progress and innovation across various sectors. As we continue to embrace these advancements, it is crucial to address the challenges they pose, ensuring that technology serves to enhance human well-being, foster inclusivity, and promote sustainable development. By doing so, we can harness the full potential of technology to create a brighter, more connected future.