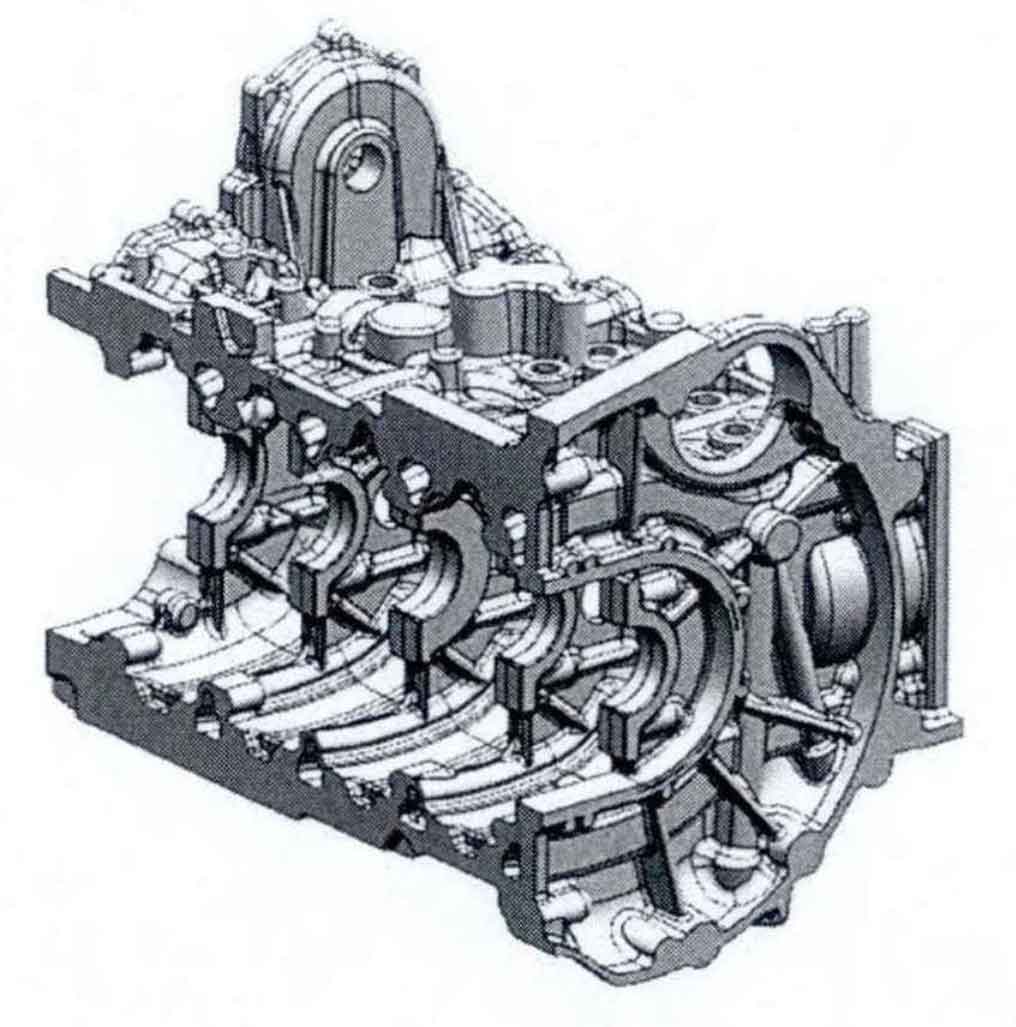

Figure 1 shows the model of a high-strength gray cast iron engine cylinder block. The main processes include raw material proportioning, smelting process, molding, core making process, pouring process and post-treatment process:

1.Ingredients; The ingredients are divided into raw materials and auxiliary materials. According to the weight percentage, the raw materials for casting production mainly include scrap steel, pig iron and recycled materials. The insufficient carbon is supplemented by the addition of carburizing agent. The auxiliary materials include ferrosilicon, ferromanganese, ferrochromium, pure tin, etc; Table 1 shows the composition requirements of main raw materials and auxiliary materials in gray cast iron:

| C | Si | Mn | S | P | Cr | Ti | Al | Fe | |

| Pig iron | 3.34 | 2.11 | 0.56 | 0.047 | 0.032 | — | — | — | Other |

| steel scrap | 0.027 | 0.022 | 0.12 | 0.011 | 0.015 | 0.031 | 0.058 | 0.051 | Other |

| Carburizing agent | 97.52 | — | — | 0.01 | — | — | — | — | Other |

| Ferrosilicon | 0.098 | 77.2 | 0.33 | 0.018 | 0.035 | 0.274 | — | 1.357 | Other |

| Ferromanganese | 6.69 | 2.47 | 69.0 | 0.03 | 0.25 | — | — | — | Other |

| ferrochrome | 6.00 | 3.00 | — | 0.04 | 0.04 | 60.0 | — | — | Other |

2.Smelting; 6000kW, 8t / h medium frequency induction furnace (Fig. 2) is used for melting of gray cast iron liquid. The outlet water temperature of molten iron is controlled at 1510 ± 30 ° C. at the same time, thermal analyzer is used to detect the content of molten iron C, and direct reading spectrometer is used to detect the content of other alloy elements. The composition control of molten iron is shown in Table 2, and its carbon equivalent CE is 3.90-4.03. Near the eutectic point of Fe GR phase diagram, it is to ensure that molten iron has good mold filling ability and graphitization ability. Make triangle test block to test the white width of gray cast iron. When the white width is ≤ 4mm, it means that the molten iron quality is qualified.

| C | Si | Mn | S | P | Cr | Sn | Ti | Fe |

| 3.30-3.40 | 1.80-1.90 | 0.75-0.85 | 0.08-0.10 | ≤0.05 | 0.10-0.15 | 0.07-0.08 | ≤0.05 | Other |

3.Modeling and core making: the upper and lower box sand molds are modeled by static pressure molding line, the main core and water jacket core are cored by cold box method, and the oil duct is cored by hot box method; After the prepared sand core is dipped, coated and dried, it is combined with a core assembling machine; During the drying process, the temperature needs to be strictly controlled to prevent excessive moisture in the sand mold and the increase of gas evolution, so as to make the casting produce air hole defects. After drying, the sand mold also needs to be polished to avoid more sand holes, slag holes and other casting defects in the later stage.

4.Pouring and inoculation; Qualified molten iron is transferred to the insulation pouring furnace through the ladle, Transfer the primary inoculant (silicon calcium barium inoculant shall be placed at the bottom of the ladle for one inoculation. Before pouring, the C content and solidification curve in molten iron shall be measured and analyzed by thermal analyzer, and the composition of other elements shall be measured by direct reading spectrometer to ensure that the composition of molten iron before box injection meets the requirements of Table 2. At the same time, the white width of gray cast iron shall still be detected, and the pouring temperature shall be controlled at 1435 ± 1 5°C 。 Carry out secondary flow inoculation (silicon strontium inoculant) during injection in the holding furnace box. The amount of inoculant added in the two times shall be calculated according to the proportion of hot metal water output, and its specifications are shown in Table 3. The second inoculation treatment is used to delay the decline of inoculant and give full play to the inoculation effect of inoculant.

| Inoculant | Si | Sr | Ca | Ba | Fe | Granularity(mm) | Additive |

| Silicon calcium barium | 72-78 | / | 1.0-3.0 | 1.5-3.0 | Other | 3-8 | 0.50-0.65 |

| Strontium silicate | 72-78 | 0.6-1.5 | / | / | Other | 0.2-0.7 | 0.09-0.13 |

5.Cooling and cleaning: the castings after box injection shall be unpacked after 2h, and then enter the sand dropping system to obtain the castings with a small amount of molding sand on the surface. After rough and fine polishing, the sand on the surface shall be removed, and then the pouring riser shall be removed, and the burrs and excess parts shall be polished to obtain the castings.