Steel casting has long been valued for its strength, durability, and versatility. In recent years, advancements in metallurgical techniques and alloy compositions have opened up new possibilities for high-strength steel casting. This article delves into the realm of high-strength steel casting, exploring its applications, benefits, and the challenges involved in pushing the boundaries of strength and performance.

- High-Strength Steel Alloys: High-strength steel alloys, such as low-alloy and micro-alloyed steels, offer superior mechanical properties compared to conventional steel grades. These alloys exhibit enhanced tensile strength, yield strength, and impact resistance, making them ideal for demanding applications that require exceptional strength and durability. The article explores the composition and characteristics of these alloys, highlighting their suitability for high-strength steel casting.

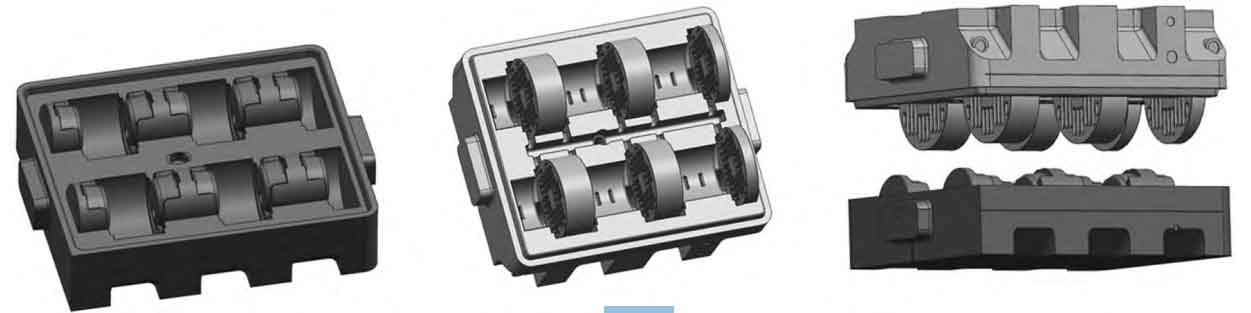

- Automotive and Aerospace Applications: High-strength steel casting finds significant applications in the automotive and aerospace industries. In the automotive sector, it enables the production of lightweight, yet robust components that enhance vehicle safety and fuel efficiency. From engine blocks and transmission housings to suspension components, high-strength steel casting is pushing the boundaries of performance in the automotive field. Similarly, in the aerospace industry, high-strength steel castings contribute to the production of critical components, such as turbine blades, landing gear, and structural elements, ensuring the safety and reliability of aircraft.

- Heavy Machinery and Equipment: The use of high-strength steel casting extends to heavy machinery and equipment, where the need for ruggedness and load-bearing capacity is paramount. Components like crane hooks, excavator buckets, and mining equipment benefit from the high-strength properties of steel casting, allowing for increased durability and extended service life. The article explores the advantages of high-strength steel castings in demanding industrial applications, highlighting the potential for improved productivity and reduced downtime.

- Energy and Infrastructure: High-strength steel casting plays a crucial role in the energy and infrastructure sectors. It enables the construction of robust structures, such as bridges, offshore platforms, and power plant components, which need to withstand challenging environments and heavy loads. By pushing the boundaries of strength, high-strength steel casting contributes to the development of safer and more efficient energy and infrastructure systems.

- Challenges and Considerations: While high-strength steel casting offers numerous advantages, it also presents challenges that need to be addressed. The article explores considerations such as alloy selection, casting process optimization, heat treatment techniques, and quality control measures to ensure the integrity and performance of high-strength steel castings. It also discusses the importance of collaboration between manufacturers, designers, and material specialists to overcome these challenges and unlock the full potential of high-strength steel casting.

High-strength steel casting has revolutionized industries that demand exceptional strength and performance. By pushing the boundaries of strength and durability, high-strength steel castings have expanded the possibilities for lightweight designs, improved fuel efficiency, and enhanced safety across various sectors. However, successful implementation requires a thorough understanding of alloy compositions, casting processes, and quality control measures. As advancements continue to be made in high-strength steel casting, the limits of what can be achieved are being constantly redefined, driving innovation and shaping the future of engineering and manufacturing.