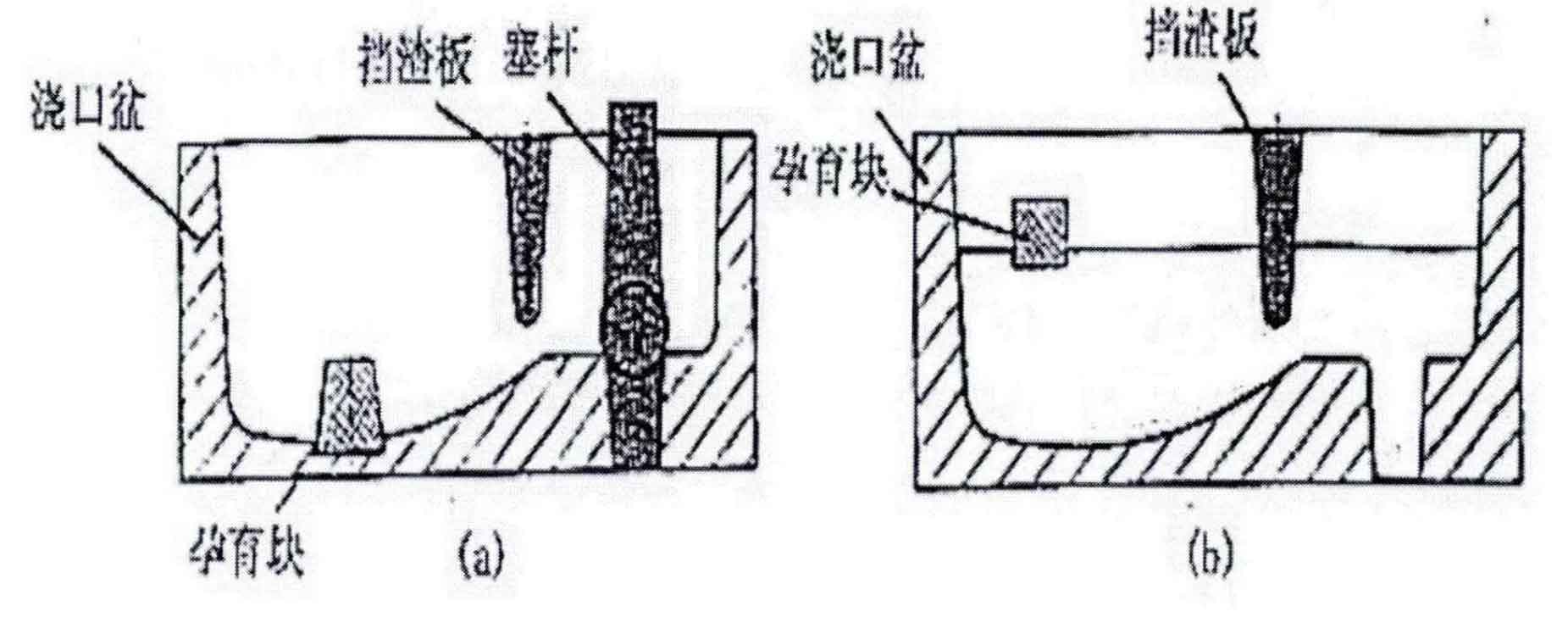

The selection of rare earth inoculated gray cast iron process depends on the addition method of inoculant, mainly including in bag inoculation, late inoculation and in mold inoculation. Because the inoculant has timeliness, that is, the inoculation effect of inoculant decreases with the extension of time, the addition of inoculant is generally selected in the pouring process or directly in the mold, Make the inoculation time equal to the solidification time of gray iron castings as far as possible to improve the inoculation effect, that is, late inoculation and in mold inoculation are generally selected. Nowadays, the commonly used inoculation processes include: porous plug method, punching method, tundish method, wire feeding method, in mold treatment method, injection method, etc., of which the most widely used is punching method. As shown in the figure, it is a typical in mold inoculation method.

Figure (a) shows that the block inoculant is fixed at the bottom of the sprue basin and gradually dissolved into the molten iron during pouring. When the amount of molten iron is large, the stopper can be used, which is more conducive to the dissolution of inoculant into the molten iron and evenly distributed in the molten iron; Figure (b) shows that the block inoculant is placed in the gate basin and floats on the molten iron during pouring. When this method is adopted, it should be ensured that the size of the inoculant block is still larger than the diameter of the straight gate after it is partially dissolved in the molten iron.

The inoculation method has a significant impact on the properties of gray cast iron. Among the commonly used inoculation methods of gray cast iron, the inoculation effect of instantaneous inoculation (i.e. flow inoculation) is the best. Instantaneous inoculation can significantly improve the microstructure of gray cast iron, reduce the content of undercooled graphite, and will not produce coarse graphite; The gray cast iron cast by ladle inoculation will produce coarse graphite, which means that instantaneous inoculation can maximize the promotion of graphite nucleation, but will not affect the growth of graphite. When the gray cast iron is inoculated instantaneously, the particle size of inoculant should be controlled between 0.3-0.5mm, and the dosage is only between 0.1-0.15%. The time interval between the addition of instantaneous incubation and solidification is the shortest, which is conducive to avoiding the occurrence of inoculation recession.