This paper provides an in – depth exploration of the casting processes and numerical simulation techniques for large – scale castings. It first elaborates on the significance of large – scale castings in the equipment manufacturing industry and the challenges faced in the casting process. Then, it reviews the application progress of various casting processes, including sand casting, metal – mold casting, die casting, and lost – foam casting, etc., and compares their advantages, disadvantages, and applicable scopes through tables. Next, the development of numerical simulation technology in casting, such as the simulation of temperature field, flow field, stress/strain field, and microstructure, is introduced in detail, with numerous case studies to illustrate its practical application. Finally, the future development directions of modern casting, including intelligent, green, and precision casting, are prospected, aiming to provide a comprehensive reference for the development of the casting industry.

1. Introduction

The equipment manufacturing industry serves as a crucial pillar of the national economy, reflecting a country’s comprehensive competitiveness and industrial strength. The casting industry, an essential part of the equipment manufacturing industry, supplies various important components, playing a vital role in promoting the development of the manufacturing field. Large – scale casting technology is a key engineering technology in China’s equipment manufacturing industry and an important indicator to measure the maturity and competitiveness of a country’s and region’s industries.

With the continuous development of key fields such as national defense, aerospace, and high – speed rail, the demand for large – scale castings of hundreds of tons or even larger sizes is increasing rapidly, and the requirements for casting quality are becoming more and more stringent. However, there are still some gaps between China and developed countries in the preparation of large – scale and high – end precision castings. In the casting process of large – scale castings, various factors can lead to quality defects such as shrinkage cavities, porosity, cracks, and gas entrapment, which seriously affect the quality of castings. Therefore, it is of great significance to study advanced casting processes and numerical simulation techniques to improve the quality of large – scale castings.

2. Application Progress of Casting Processes for Large – Scale Castings

2.1 Sand Casting

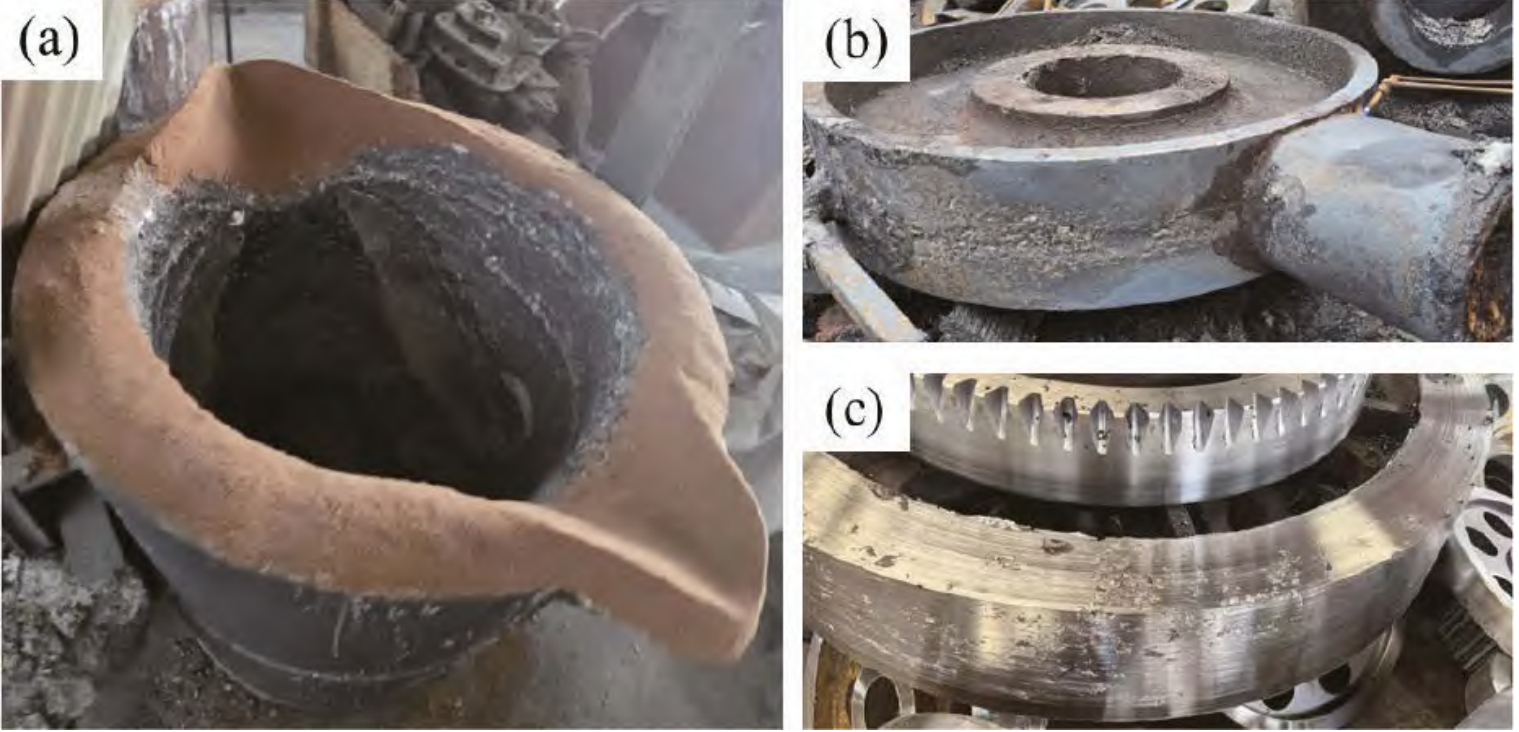

Sand casting is widely used for manufacturing medium – to – large – sized thick – walled castings. It has the advantages of low cost, high production flexibility, and wide application range. For example, in the production of large – scale titanium alloy pump body castings, the sand casting process can meet the requirements of chemical composition, mechanical properties, and dimensional accuracy. The titanium alloy pump body castings developed by a special sand casting process have good internal and surface quality, and their mechanical properties meet the requirements of ASTM B367 C3.

Compared with investment casting, titanium alloy sand casting has the advantages of being able to produce large – scale castings, low cost, and high efficiency. It is one of the necessary processes for manufacturing some large and complex castings. However, sand casting also has some disadvantages, such as relatively low dimensional accuracy and surface finish, and the need for post – processing in some cases.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| Low cost, high production flexibility, wide application range | Low dimensional accuracy, relatively rough surface finish | Medium – to – large – sized thick – walled castings, especially for some large and complex structures |

2.2 Metal – Mold Casting

Metal – mold casting offers advantages such as fast cooling speed of castings, fine – grained structure, and high surface finish. It is suitable for mass – producing high – precision castings. Although the cost of metal molds is relatively high, their high reusability and short casting time make them cost – effective for large – scale production.

For instance, by combining MAGMA software simulation and metal – mold casting technology, Ge Chunli predicted the casting defects of high – power wind turbine spindles and successfully cast wind turbine spindles that meet the design requirements through measures such as placing chills. Metal – mold casting is often used in industries that require high – precision and high – strength castings, such as the automotive and aerospace industries.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| Fast cooling speed, fine – grained structure, high surface finish, suitable for mass production | High mold cost | High – precision and high – strength castings, especially for mass – produced parts in automotive, aerospace, etc. |

2.3 Lost – Foam Casting

Lost – foam casting uses foam molds instead of ordinary molds. During the casting process, the foam mold is vaporized and disappears by the liquid metal, and then the liquid metal cools and solidifies to form the casting. This process has the advantages of flexible process, high casting accuracy, and no need for mold disassembly.

In the field of steel and iron casting, lost – foam casting has always occupied a large proportion. For aluminum – magnesium alloy lost – foam casting, the control of pouring quality, the development of low – temperature vaporizing foam mold materials, and the improvement of high – strength and breathable coatings are the key research topics. Vacuum low – pressure lost – foam casting technology can solve the problems of mold collapse or expansion during the lost – foam casting process. Vibration lost – foam casting technology can refine the solidification structure of castings, improve feeding, and enhance the mechanical properties of castings. Pressure lost – foam casting technology can also refine the structure, reduce defects, and improve the physical properties of castings.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| Flexible process, high casting accuracy, no need for mold disassembly | Challenges in controlling pouring quality for some alloys, need for specific foam materials and coatings | Steel, iron castings, and gradually being applied to aluminum – magnesium alloy castings |

2.4 Investment Precision Casting

Investment precision casting is an important casting process developed from the investment casting process. It emphasizes obtaining castings with high dimensional accuracy and good surface quality. This process is widely used in manufacturing high – precision and complex – shaped metal castings.

The process involves making precise wax molds, preparing high – temperature – resistant ceramic shells through processes such as dipping, sand – hanging, hardening, and dewaxing, and then injecting liquid metal into the mold cavity. Ran Xing conducted research on the precision casting of large and complex titanium alloy castings, and determined that reasonable mold – making parameters and wax mold anti – deformation measures are the keys to controlling the dimensional accuracy of large and complex titanium alloy castings. In foreign developed countries, investment precision casting is widely used in aerospace, military, and other high – end fields. In China, there is still a certain gap in the high – value – added casting output in these fields, and there are also challenges in internal and external quality control methods and the development of high – stability shell coatings.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| High dimensional accuracy, good surface quality, high material utilization rate, can reduce subsequent processing | Complex process, high cost, challenges in high – value – added casting production in some fields | High – precision and complex – shaped metal castings, especially for aerospace, military, and other high – end applications |

2.5 Die Casting

Die casting is an advanced casting technology for manufacturing large – scale castings in modern metal processing. Under high – speed and high – pressure conditions, liquid metal is filled into the mold, and the casting is formed by solidifying under a certain pressure. High pressure and high speed are the key factors to ensure the quality of die – castings.

Die casting technology has a high production efficiency, simple process, and excellent casting quality. It can save a large number of machining processes and resources. High – performance magnesium and aluminum alloy die – casting technology is an important application area of die casting. However, die casting also has some limitations, such as high equipment cost and the need for high – pressure equipment and molds.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| High production efficiency, simple process, excellent casting quality, can save machining processes and resources | High equipment cost, need for high – pressure equipment and molds | High – performance magnesium and aluminum alloy castings, and some other non – ferrous metal castings with high – volume production requirements |

2.6 Low – Pressure Casting

Low – pressure casting is the earliest anti – gravity casting technology. It fills the mold with metal liquid from bottom to top by applying a low pressure on the surface of the molten metal through compressed air input. It is often used for manufacturing thin – walled and complex – structured castings.

Although the production efficiency of low – pressure casting is low and the equipment cost is high, in recent years, China’s low – pressure casting technology for high – quality thin – walled and complex castings has been constantly innovating. For example, Ma Juncheng successfully solved the problems of shrinkage cavities, porosity, and gas holes in large – scale aluminum alloy gearbox castings for high – speed trains by using resin sand molding and low – pressure casting technology, combined with CAE simulation technology. Differential pressure casting, a derivative of low – pressure casting, can obtain castings with higher density by increasing the pressure during the solidification of castings.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| Suitable for thin – walled and complex – structured castings, can achieve better filling effect | Low production efficiency, high equipment cost | Thin – walled and complex – structured castings, especially for aluminum alloy and some other non – ferrous metal castings |

2.7 Centrifugal Casting

Centrifugal casting involves pouring metal liquid into a high – speed rotating mold, and the metal liquid is evenly distributed on the inner surface of the mold by centrifugal force to form the casting. Castings produced by centrifugal casting have high quality and are widely used in industries such as marine, aerospace, and metallurgy.

Centrifugal casting has many advantages, such as being good at producing hollow cylindrical castings with high production efficiency and low cost, no need for risers and gates, high metal utilization rate, wide range of applicable alloys, and the ability to make impurities float on the inner surface of the casting to improve the internal quality. It is especially suitable for manufacturing parts with special requirements for internal quality and structure, such as pipes and cylinder liners.

| Advantages | Disadvantages | Applicable Scope |

|---|---|---|

| High – quality castings, suitable for producing hollow cylindrical castings, high production efficiency, high metal utilization rate | Limited to certain shapes (mainly cylindrical or rotation – symmetric parts) | Marine, aerospace, metallurgy, and other industries, especially for pipes, cylinder liners, and other rotation – symmetric parts |

3. Development of Numerical Simulation Technology in Casting

3.1 Development of Numerical Simulation of Casting Filling Process Abroad

Computer – aided casting simulation technology, also known as casting CAE technology, has a long history of development. Since the 1960s and 1970s, scientists have started to consider combining casting with computers to improve casting quality and production efficiency. In 1962, Fursund first used a computer to simulate the casting temperature field, applying the finite – difference method to the heat transfer calculation in the casting simulation process, opening up a new field of computer – based numerical calculation for casting solidification theory.

In the 1970s, Nyiama et al. explored the “change function method” and the direct difference method, and extended the numerical simulation from two – dimensional to three – dimensional. They also proposed the use of the \(G/\sqrt{R}<C_{Niyama}\) criterion to judge the shrinkage porosity defects in casting, enabling the prediction and evaluation of shrinkage porosity.

With the continuous improvement of the numerical simulation theory for casting filling and solidification processes, various casting simulation software has emerged. Many commercial software systems, such as ProCAST, MAGMA, Forcast, Novasolid, CASTEM, SIMULOR, and CastCAE, have been applied in numerous casting enterprises. These software can accurately simulate and analyze various casting processes and optimize the casting process through post – processing techniques.

| Software Name | Country of Origin | Algorithm | Maximum Processable Grid Number | Application Scope |

|---|---|---|---|---|

| MAGMAsoft | Germany | FDM/FEM | Not limited by the software | All kinds of casting, can simulate temperature field, stress field, and flow field |

| ProCAST | USA | FEM | Not limited by the software | All kinds of casting, can simulate temperature field, stress field, and flow field |

| SIMULOR | France | FVM | – | Multiple casting types, can simulate temperature field and stress field |

| CASTEM | Japan | FDM | – | Multiple casting types, can simulate temperature field, stress field, and flow field |

3.2 Development of Numerical Simulation of Casting Filling Process in China

Although the development of domestic simulation software started relatively late, through the introduction and integration of international advanced casting numerical simulation technology theories, the casting simulation technology in China has achieved rapid progress and has uniquely developed research fields that suit the national conditions.

FT – Star, the first commercial software in the domestic casting field, can quantitatively predict the volume and distribution of shrinkage cavities and porosity in castings based on three – dimensional modeling of castings, finite – difference grid division, and certain parameter conditions and thermal physical property parameter libraries. Huazhu CAE can optimize the casting process by simulating the flow field and temperature field during the filling and solidification processes of castings. It has applicable modules for different materials and casting methods. EasyCast is an integrated software system that combines three – dimensional solid modeling file interfaces, computational grid division, casting process simulation, casting defect prediction, and result display.

Many domestic research institutions and scholars have also carried out in – depth research on casting numerical simulation. For example, Yu Qiuping from Northwestern Polytechnical University applied casting simulation technology to the research of macro and groove segregation in ingot solidification; Liu Baicheng from Tsinghua University and Huazhong University of Science and Technology mastered advanced point – gating and post – gating technologies in the field of large and extra – large castings.

4. Research Progress of Numerical Simulation Technology in the Casting Process of Large – Scale Castings

4.1 Temperature Field Simulation during Solidification Process

The core of the casting CAE system is to establish mathematical models and simulate the physical phenomena in the casting process. These models are usually based on the Fourier heat – conduction differential equation, which reveals the relationship between heat flux density and temperature gradient in a continuous temperature field. The emergence of software for calculating thermal physical properties makes it more convenient to obtain thermal physical property parameters.

By simulating the temperature field changes during the solidification process of large – scale castings, it is possible to predict the solidification process, hot spots, temperature gradients, riser feeding conditions, liquid – phase regions, and shrinkage cavity and porosity defects, providing guidance for actual production. For example, Chen et al. optimized the casting process by predicting the defects in the casting during the solidification process based on the temperature field and solidification field simulation results of ProCAST software during the filling and solidification processes. Li Zhongyao et al. studied the influence of process parameters such as pouring temperature, mold pre – heating temperature, filling speed, and holding pressure on the distribution law of shrinkage cavity defects in low – pressure casting wheels through temperature field simulation.

In the simulation of large – scale thin – walled and complex aluminum alloy cabins, Song Chunli et al. used three software, NovaCAST, JSCAST, and EasyCast, to conduct low – pressure casting simulations. The simulation results showed that the solidification sequences of the castings and the gating systems predicted by the three software were basically the same, and the prediction capabilities of the three software for the location of shrinkage cavity defects were almost the same.

| Case | Software Used | Simulation Content | Results |

|---|---|---|---|

| Casting of large – scale thin – walled and complex aluminum alloy cabins | NovaCAST, JSCAST, EasyCast | Temperature field simulation during solidification process, defect prediction | Similar solidification sequences and defect prediction results, but differences in grid division and model boundary fitting |

| Optimization of casting process of aluminum alloy flywheel housing | ProCAST | Temperature field simulation during filling and solidification processes, prediction of alloy melt flow law and defect distribution | Optimized process parameters, reduced defects, and obtained high – quality flywheel housing |

4.2 Flow Field Simulation during Filling Process and Coupled Simulation of Flow Field and Temperature Field

With the emergence of numerical methods such as SIMPLE, MAC/SMAC, SOLA – VOF, and PROJECTION – LEVEL_SET, the simulation accuracy of the flow field has been significantly improved. Flow – filling simulation can optimize the casting process, especially in aspects such as stable pouring analysis, velocity field distribution evaluation, and defect prediction.

Tian Xiaodong et al. optimized and improved the casting process plan of the machine – tool spindle box by simulating the flow field. By comparing the flow field simulation results of the side inner gating and bottom inner gating schemes using ProCAST software, they found that the bottom inner gating filling scheme was more reasonable. By adding risers for feeding, the shrinkage – type solidification defects were avoided, and the optimal process plan was obtained.

The coupled simulation of the flow field and temperature field is a crucial step, as they jointly affect the solidification process and the final quality of the casting. The temperature distribution of the liquid metal affects its density and viscosity, thereby changing the flow velocity and flow pattern. The vortex and turbulent structure of the flow field affect the heat transfer rate and distribution. For example, Wang used COMSOL software to conduct a coupled simulation of the flow field and temperature field during the direct – chill casting of a φ300mm ingot, proving that strong melt shearing can increase the width of the two – phase zone and significantly enhance melt convection.

| Case | Software Used | Simulation Content | Results |

|---|---|---|---|

| Optimization of casting process of machine – tool spindle box | ProCAST | Flow field simulation, comparison of different gating schemes, temperature field simulation, and defect prediction | The bottom inner gating scheme is more reasonable, and adding risers can avoid shrinkage – type defects |

| Direct – chill casting of φ300mm ingot | COMSOL | Coupled simulation of flow field and temperature field | Strong melt shearing has a significant impact on the solidification process |

4.3 Stress/Strain Simulation

The solidification process of castings includes three stages: liquid state, semi – solid state (the co – existence zone of solid and liquid phases), and solid state. During this period, the mechanical and thermophysical properties of the material change greatly, and the co – existence of the three regions occurs. The solid – liquid two – phase region is the core of stress numerical simulation, and many casting defects such as shrinkage cavities, porosity, hot cracks, and gas entrapment occur in this stage. Stress analysis during this period is very important for predicting defects, especially hot crack defects, residual stress, and stress concentration.

For the frame casting of a jaw crusher, stress – strain simulation results show that most areas of the frame have internal stress. By performing further heat treatment at the stress – concentration areas, the stress can be eliminated, ensuring the strength of the frame and obtaining better mechanical properties.

| Case | Research Method | Results |

|---|---|---|

| Double – layer shell – type hollow mold | Stress – field numerical simulation | Reduced crack tendency of the hollow sand mold and residual stress of the casting |

| Al – Mg alloy solidification | Thermal stress analysis using cooling – rate – dependent parameters | Predicted hot – tearing trend |

| Jaw crusher frame casting | Stress – strain simulation | Identified internal stress, and heat treatment was used to improve mechanical properties |

4.4 Microstructure Performance Simulation

In the casting process, microstructure simulation is based on solidification theory and thermodynamics principles. It uses mathematical models to describe the physical and chemical changes of the solidification of molten metal. Microstructure simulation can predict the internal structure characteristics of castings, such as grain size, grain – boundary distribution, and segregation degree.

Zhang Lechen used the phase – field method to simulate the dendritic growth process of Al0.035Ni alloy under different time – step lengths, anisotropy coefficients, and undercooling degrees, and analyzed the influence of undercooling degree on solute distribution. The results show that the greater the undercooling degree, the greater the tip growth rate of dendrites and the smaller the corresponding tip nucleation radius. Gao Ting constructed 2D and 3D phase – field models using the KKS model to explore the 3D microstructure growth mechanism of Fe – 1.5%C alloy during the solidification stage. The results show that the length of dendritic growth varies significantly under different cooling rates, and the 3D phase – field simulation is more accurate in predicting dendritic growth than the 2D simulation.

Xun Menghua conducted a numerical simulation of the solidification structure of L605 centrifugal cast pipes and compared the simulation results with the actual casting trial – production results. The results show that the microstructure simulation results of the centrifugal cast pipes obtained by software are consistent with the trial – production results, which can provide help for actual production.

| Researcher | Alloy Studied | Simulation Method | Research Content | Results |

|---|---|---|---|---|

| Zhang Lechen | Al0.035Ni alloy | Phase – field method | Dendritic growth process under different conditions | Influence of undercooling degree on solute distribution and dendritic growth |

| Gao Ting | Fe – 1.5%C alloy | KKS – based phase – field models | 3D microstructure growth mechanism during solidification | Difference in dendritic growth under different cooling rates, superiority of 3D simulation |

| Xun Menghua | L605 alloy | ProCAST’s CAFE module | Solidification structure of centrifugal cast pipes | Consistency between simulation and actual trial – production results |

4.5 Other Simulations in Casting

- Casting Segregation Simulation: Macro – segregation refers to the non – uniform distribution of alloy components in the casting or ingot solidification cross – section on a scale larger than the grain size. Its formation is closely related to the flow, heat transfer, and solidification of molten steel during the casting process. Along with the formation of segregation, there are casting quality defects such as stress concentration, shrinkage cavities, porosity, hot cracks, and center segregation, which affect the performance of the casting. Simulation and research on eliminating macro – segregation defects are of great significance, and many scholars have achieved certain results in this area.

- Casting Melting Process Simulation: In the casting industry, melting process simulation is used to simulate and optimize various links of metal melting. By simulating the melting process, it is possible to accurately predict the metal flow, heat conduction, chemical reactions, and mass transfer in the melting furnace, helping engineers optimize the operating parameters in the furnace and control the metal composition, that is, the proportion of furnace charge, to improve the uniformity and quality stability of the alloy. This technology can also be used to predict non – uniform mixing, gas inclusions, and impurity distribution, as well as optimize the design of combustion equipment and heating systems, thereby improving production efficiency and energy utilization efficiency.

- Casting Heat Treatment Simulation: In the casting industry, casting heat treatment simulation is an important technology used to simulate and optimize the temperature field, phase – change behavior, and microstructure evolution of castings during the heat treatment process. Through heat treatment simulation, it is possible to accurately predict the influence of different heating, holding, and cooling process parameters on the structure and properties of castings, so as to optimize the heat treatment process, improve the mechanical properties, wear resistance, and corrosion resistance of castings. This technology can also be used to simulate the heat treatment process of castings with complex geometric shapes, helping engineers design reasonable heat treatment process plans, improve production efficiency, and product quality.

5. Overview of the Development Direction of Modern Casting

5.1 Intelligent Casting: Industry 4.0 Technology Upgrade and Digital Integration

- Building an Intelligent Production System: Industry 4.0 technology realizes the automation and intelligence of the entire casting process through technologies such as the Internet of Things, industrial robots, and cloud computing. Sensors are used to collect the operation data of casting equipment in real – time through the Internet of Things and big data. Big data is used to optimize process parameters, and defect prediction and cooling route optimization are carried out to improve the production yield.

- Digital Management and Decision – Making Support: Based on cloud computing and edge computing, a digital platform for the entire casting process is built, and a three – dimensional digital model of the casting process is established to achieve visual monitoring of the production process and predictive maintenance. For example, the Shared Intelligent Casting Industry Innovation Center has created a “cloud + network + factory” architecture, and the casting cloud platform provides remote process optimization and fault – troubleshooting guidance for factories.

- In – Depth Application of Advanced Manufacturing Technologies: Software such as ANSYS, AnyCasting, and ProCAST is used to simulate the flow, solidification process, and stress distribution of molten metal, to identify potential defects such as shrinkage cavities and deformation in advance. A casting process database is established, and AI algorithms are used to automatically optimize gating system design, mold design, and heat treatment parameters. Technologies such as 3D printing, intelligent material ratio and traceability, and additive manufacturing are used to promote the transformation of the casting industry towards personalized customization and improve the yield of integrated castings.

5.2 Green Manufacturing and Sustainable Development Trends

- Low – Carbon Processes and Energy Efficiency Improvement: Technologies such as waste – heat recovery and high – efficiency melting furnaces are adopted to reduce energy consumption. AI is combined to optimize energy distribution and improve energy efficiency. Clean energy is gradually used to replace traditional fuel energy to significantly reduce carbon emissions.

- Resource Recycling and Waste Utilization: An intelligent casting production line integrates a waste recycling system. Through digital tracking and real – time monitoring by big data, the high – efficiency recycling of metal resources is realized.

- Full – Life – Cycle Management: Enterprises build green factories, combining energy – saving and digital intelligent management to achieve the green and low – carbon transformation of the entire life cycle of casting production.

6. Conclusions and Outlook

6.1 Conclusions

In the field of large – scale casting in China, significant progress has been made in the optimization of traditional processes and the application of numerical simulation technologies. However, there are still key challenges:

- Differences in Process Maturity: Traditional casting processes in China, such as sand casting, die casting, and centrifugal casting, are approaching maturity, but there are still technical bottlenecks in high – end fields. In the investment precision casting field, the proportion of high – value – added castings is low, and the preparation technology of complex ceramic cores needs to be broken through. In differential pressure casting, basic research is insufficient, and the performance and control accuracy of supporting equipment need to be improved. Although lost – foam casting technology has been mainly applied in aluminum – magnesium alloys, there is still a gap in high – precision and complex foam pattern processing technologies and equipment. The high – end and practical application of casting technology remains a goal that China needs to strive to achieve.

- Simulation Technology Bottlenecks: The development level of casting numerical simulation technologies at home and abroad is relatively high, which can achieve accurate simulation of temperature fields, flow fields, and stress fields, effectively guiding the optimization of casting processes. However, although domestic simulation software such as Huazhu CAE and FT – Star has made breakthroughs and can support basic process optimization, there are still gaps compared with foreign software in terms of multi – field coupling accuracy, microstructure prediction, and material database completeness, restricting the quantitative analysis of complex defects and the optimization of the entire process.

6.2 Outlook

- Breakthroughs in Intelligent Casting Technologies: Build a three – dimensional dynamic model covering melting – filling – solidification, combine AI algorithms to achieve quantitative defect prediction (such as the volume prediction error of shrinkage cavities ≤ 5%), and construct a full – process digital twin. Promote the coordinated development of industrial manufacturing and the Internet of Things, establish an industry – level process database, and achieve cross – enterprise process parameter optimization and remote equipment operation and maintenance through the casting cloud platform.

- Collaborative Innovation of High – End Materials and Green Manufacturing: Develop lightweight and high – temperature – resistant alloys (such as titanium – based and nickel – based high – temperature alloys) to meet the requirements of high – performance castings in aerospace, new energy, and other fields. Develop hydrogen – energy melting, waste – heat recovery, and other technologies to promote the replacement of traditional energy sources with clean energy and achieve low – carbon process innovation. Integrate waste recycling systems through intelligent casting production lines, and use digital tracking and big – data real – time monitoring to achieve the high – efficiency recycling of metal resources.

- Promote the Development of Domestic Casting Simulation Technology: Integrate multi – field coupling simulations of flow fields, temperature fields, stress fields, and electromagnetic fields to explain the formation mechanism of complex defects. Promote the innovation of multi – phase – field microstructure simulation technology to support the development of high – performance alloys.

In conclusion, with continuous technological innovation and research efforts, the casting industry is expected to overcome existing challenges and achieve more advanced development in the future, meeting the growing demands of various industries for high – quality large – scale castings.