As a key component of the automotive chassis, the steering knuckle plays an important role in the driving process. The loads sustained during the process are complex and diverse, so their strength The requirements for strength and impact resistance are high. Currently, most steering knuckle parts are made of Ductile iron sand casting production. With the development of automotive lightweight, The material of steering knuckle is also changing from ductile iron to aluminum alloy and other lightweight materials Material transformation. The transformation of steering knuckles under different working conditions Stiffness, strength and fatigue life are the analysis objectives, and the structure and Shape optimization, the weight of the optimized part is reduced by about 9%; Topology optimization is used to carry out lightweight design for the aluminum alloy automotive steering knuckle structure, Under the premise of ensuring strength, the quality of the steering knuckle is reduced by 48%. However, Previously, research mostly focused on conceptual design and simulation analysis, with less consideration for The influence of subsequent forming processes on the structure of the steering knuckle, therefore structural optimization The formation of the rear steering knuckle is more difficult.

Extrusion casting process has strong applicability, with dense casting structure and mechanical properties Excellent, high quality, high dimensional accuracy, suitable for some mechanical properties We are looking for high-quality structural parts, such as automotive hubs, steering knuckles, frames, and connecting rods. It is an ideal forming process for achieving lightweight automotive components. This research Combining topology optimization method with squeeze casting process, using aluminum Alloy instead of ductile iron, topology optimization of the existing steering knuckle structure and completed the extrusion casting of aluminum through simulation verification and mechanical performance validation. Development of alloy automotive steering knuckles.

Topology optimization of aluminum alloy steering knuckle

Topology optimization is to find the optimal solution within a fixed design space, The optimal material distribution path for performance, resulting in the lightest-weight structural design scheme. Currently commonly used methods include homogenization method, variable density method (SIMP method, level set method, evolutionary structural optimization method (ESO), independent continuous mapping methods such as iterative constrained minimization (ICM). Among them, the variable density method is characterized by fewer design variables, ease of implementation, and robustness. It is widely used in engineering and business software due to its high efficiency. Common models in the variable density method include the solid isotropic material penalty the model (SIMP) and the rational approximation model (RAMP) of material properties. The model penalizes the intermediate density by introducing a penalty factor, making the The density values cluster towards the 0/1 ends, with 0 indicating no material at the spatial point and 1 indicating It indicates that the area is occupied by solid materials. Optimization model for discrete variables of 0/1 The topological optimization model of continuous variables can be well obtained. Due to different operating conditions during driving, the steering knuckle The load under different working conditions is also different. When there are multiple working conditions, each The optimal solution of topology optimization under different operating conditions is also different. Therefore, in order to calculate It is convenient to choose a common objective function for the steering knuckle. Often the goal is to maximize the stiffness. At the same time, it is also necessary to know the working conditions of each component. The relative importance of different objectives can often be measured using trade-off planning methods and the analytic hierarchy process in operations research. Based on the actual situation, it is recognized that The relative importance of the operating conditions is the same. The multi-condition topology optimization of the steering knuckle is The mathematical model of the optimization is:

Where, K and U are the stiffness and displacement matrix of the unit, respectively; m is the load condition Total number, take m=5; ωk is the weight for the kth condition, since each The importance of each operating condition is equivalent, so the weight coefficient of each operating condition is 1; q is Punishment factor, and q≥2, generally taking q=3; Ck(ρ) is the flexibility of the kth condition degree objective function; Cmax k is the maximum value of flexibility under the kth condition, which is determined by Strain energy obtained from the original structural analysis before chemical modification; Cmin k is the flexibility for the kth condition The minimum value of , which is obtained by analyzing the model after filling the material, is Variable energy; ρ is the design variable, which is the density of the unit material; V0 V(ρ) is the best The volume of the structure before and after the transformation; f is the volume constraint fraction, taken as f=30%; σj (x) is the stress of the jth node; σ0 As the stress limit, take 230 MPa.

Establishment of finite element model

Based on the model of ductile iron steering knuckle, the original assembly relationship is retained Based on the BIM technology, a maximum solid model of the aluminum alloy steering knuckle is established and imported Perform grid division in hypermesh, with grid size of 1 mm (model The minimum size is 1 mm). Figure 1 shows the aluminum alloy steering knuckle topology after dividing the grid The circle part is not set due to the presence of mating surfaces. The gray area is the design space, which is the topological optimization region.

The elastic modulus of the aluminum alloy steering knuckle is defined as 72.4 GPa, and the Poisson’s ratio is The ratio is 0.33, and the density is 2700 kg/m3. The car is driving on different road conditions When the steering angle is different, the load on the steering knuckle is also different. According to the actual situation, 4 Five types of work: double full load, unilateral overpass, overpass, forward braking, and forward acceleration When subjected to different load conditions, the steering knuckle is not In the completely static state, the inertial release method is used, which balances external forces through inertial forces and ignores node displacements. The virtual The constraint method of the constraint point. For inertia release analysis of the steering knuckle, it is necessary to directly Apply a load, the location of the installation point and the applied load. In coordinates Find the steering knuckle, wheel center, lower arm, steering tie rod, and shock absorber in the system and the location of the brake caliper connection point, and then establish the RBE3 flexible single The element of the yuan will be connected to the five connection points mentioned above. Finally, the forces (Fx and Fy and Fz ) and torque (Tx and Ty and Tz ) are applied to the connection points of the steering knuckle.

Topology optimization analysis and results

When creating a steering knuckle topology optimization task, it is necessary to consider multiple operating conditions comprehensively degree as the objective function, and set the volume fraction as the optimization constraint to optimize its volume. Set the upper limit to 30% (i.e., the optimized/unoptimized volume ratio is ≤0.3). In order to make the optimized structure meet the strength requirements, the The stress is less than 230 MPa.

Structural Design of Aluminum Alloy Steering Knuckle in Extrusion Casting

The topology optimization results are smoothed and imported into 3D software for structural optimization, as shown in Figure 1. Due to the The optimized area on the back of the joint is larger, reducing the overall surface by 5 mm; On this basis, the planes around the two holes connected around the brake caliper Reduce it by another 5 mm, as shown in area a in Figure 5; ② optimize due to area b The result is relatively deep. In order to ensure the structural strength of the steering knuckle, the At 8 mm, choose slotting method to reduce material; ③ because of optimization of scale in area c, The depth is relatively deep, and in order to ensure structural strength, a high-strength steel plate with a thickness of about 3 mm boss, with 10 mm diameter through hole and 5 mm blind There is one hole for each, which can also better exhaust gas during extrusion forming; ④ There are many optimizations in the center of area d, and in order to ensure strength, the entry on both sides Reducing the length of the line by about 5 mm, while also achieving compatibility with surrounding parts. ⑤ Reduce the material in the area e on both sides of the shock absorber connection point The reason is that the shape changes from convex to concave; ⑥ Due to the influence of bi-directional stripping, the There is also a large area of optimization on the front of the knuckle, as shown in area f. The area around the central hole reduces the overall surface by approximately 10 mm.

Structural design of squeeze casting

Due to the use of squeeze casting process, the requirement of demolding needs to be considered. The structure model of the joint is subjected to demolding processing, with a demolding angle of 5°, and the position of the joint is determined. In addition, some bosses and grooves are designed to facilitate subsequent play a role in positioning in mechanical processing. Due to the use of vertical extrusion casting For the machine, the metal liquid is poured from the back to the front direction, in order to ensure the The smooth and stable flow of requires the design of a diversion rib structure. Extrusion casting turn The structural design of the delivery joint is shown in the figure.

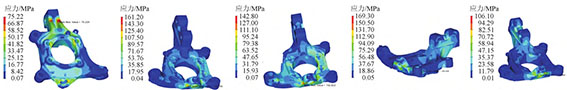

finite element strength check

Conduct finite element analysis on the aluminum alloy steering knuckle model under the same working conditions. After analysis, the force cloud map under various working conditions, The maximum stress under the condition. As shown in Figure 7, the maximum bending strength of the aluminum alloy steering knuckle after structural optimization is The stress is much lower than the yield strength of aluminum alloy (230 MPa), and the stress distribution is relatively uniform, without stress concentration, meeting the structural strength requirements. When compared to ductile iron, the aluminum alloy steering knuckle has a mass reduction of 60.9%, making it lighter The quantitative effect is significant, and the physical comparison between the two products is shown.

Mechanical property verification

In order to eliminate internal tissue segregation, improve microstructure, and enhance For mechanical properties, it is generally necessary to heat treat the steering knuckle castings. The heat treatment plan for the nodular castings T6 is 540°C×6 hours of solid solution treatment, followed by 60°C water quenching 5 minutes, aging 175℃×4 hours. Take tensile test on the steering knuckle after heat treatment mechanical property testing, the test results The mechanical properties of the steering knuckle after heat treatment meet the requirements.

Conclusion

(1) Based on the variable density topology optimization method, a steering knuckle topology optimization model was established. Mathematical model of optimization, and use HyperMesh finite element analysis software The maximum solid model of the steering knuckle was subjected to static multi-condition topology optimization. The results showed that after 29 iterations, the flexibility gradually converged and finally Tends to be stable. (2) Optimize the structure of the steering knuckle based on the topology optimization results, And combined with the squeeze casting process, the steering knuckle structure was redesigned. The strength check of the newly designed aluminum alloy steering knuckle model is shown in the result table The maximum stress on the steering knuckle under various conditions is far less than the yield strength. The quality is 60.9% lower than that of ductile iron. (3) Conduct T6 heat treatment and mechanical property inspection on the steering knuckle casting The results showed that the average tensile strength of the bulk sampling was 311.03 MPa, and the The strength of the clothing is 252.13 MPa and the elongation is 7.45%, both of which are greater than the product’s The specified value meets the product performance requirements.