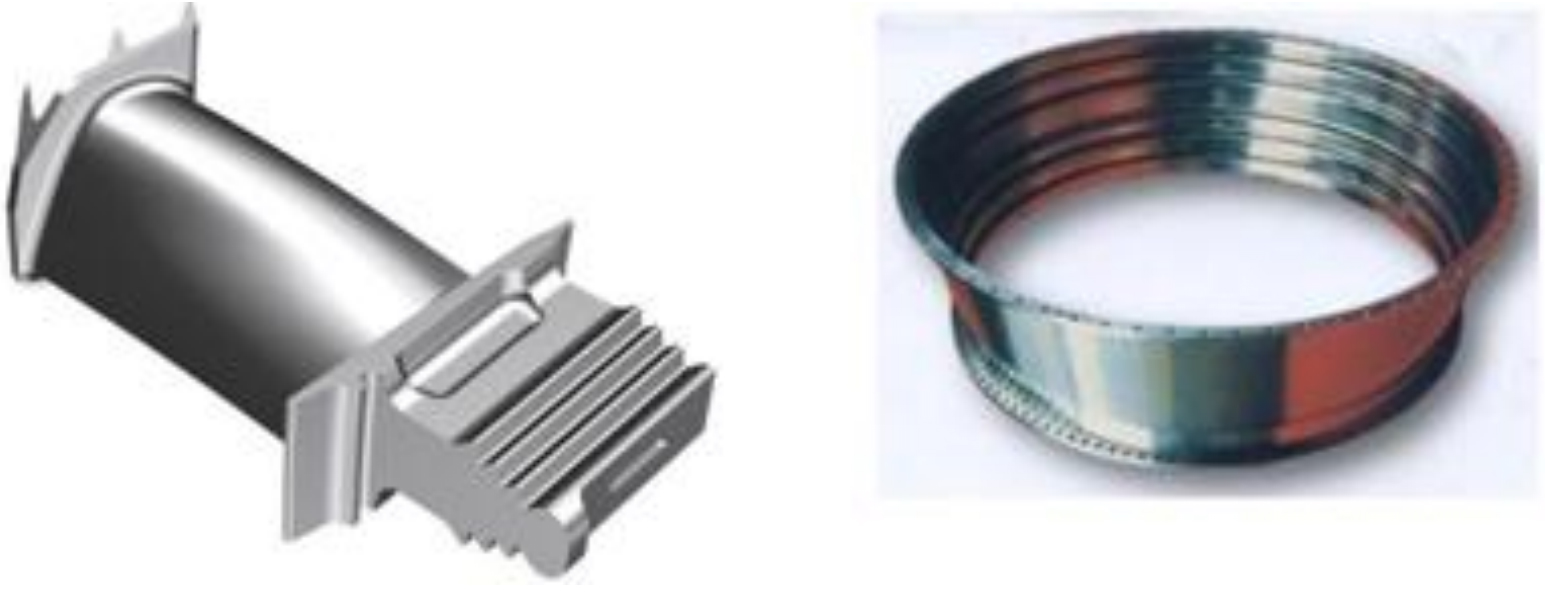

As a material near net shape technology, investment casting has the characteristics of complex casting structure, high dimensional accuracy, wide application of alloy, flexible batch and so on. Turbine blades and casings used in aviation manufacturing are manufactured by investment casting, as shown in Figure 1 below.

After decades of development, investment casting has made considerable development and progress in molding, shell making, smelting and other processes. In CAE, thanks to the rapid development of advanced technologies such as finite element analysis and computer simulation, investment casting can realize the simulation and prediction of melt filling process and solidification process, ensure the complete filling of pouring process to a great extent, and provide theoretical guidance for the customization of pouring process scheme.

The casting simulation software ProCAST can accurately simulate the filling, cooling and solidification process of castings, and predict the shrinkage porosity, air entrapment and other defects that may occur in the filling and solidification process, which greatly improves the quality of castings and reduces the unnecessary waste of traditional processes. However, compared with the development of wax mold forming and hard mold, investment casting process is cumbersome, wax film preparation takes a long time and high cost, which reduces the casting efficiency and does not have economic advantages in small batch production.