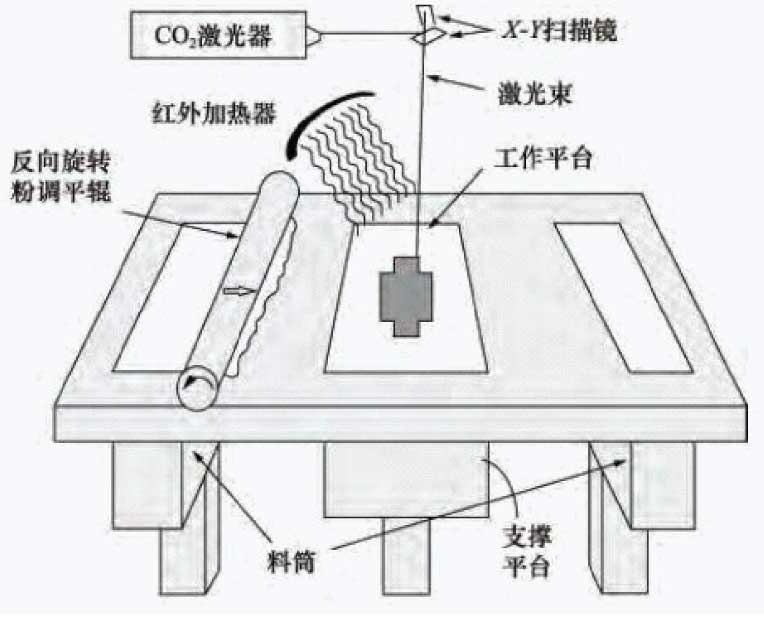

Rapid Prototyping technology relies on the point by point accumulation forming of materials, which is not restricted by the manufacturability of dies and the space accessibility of parts. It can realize the manufacturing of parts with complex shapes. It is considered as the third manufacturing technology parallel to material forming and cutting. It shows unique technological advantages in product development, rapid response of single or small batch manufacturing of complex parts. At present, there are more than 10 rapid prototyping methods, mainly including stereolithography, SLA, finalized object manufacturing LOM, selective laser sintering, SLS, fuseddeposition manufacturing, FDM, three dimensionalprinting and gluing, 3dpg, etc. Among them, the characteristics of SLA rapid prototyping are: high dimensional accuracy – accuracy level can reach ± 0.1M m, excellent surface quality – roughness can reach ra3.25 μ m, high utilization rate of raw materials, fast molding speed – scanning rate more than 8000 mm / s). Through this manufacturing process, the parts are characterized by high specification, accurate size, good dimensional consistency, high surface finish and high success rate. The application of rapid prototyping technology to sand casting technology was also developed in the 1990s. The EPC method is mainly used to replace wax mold with rapid prototype parts, which has a high forming progress and is suitable for any complex parts.

In the 1990s, rapid prototyping technology has been applied to investment casting in various countries, which can make any alloy parts. Some developed countries, such as North America, Japan, Western Europe and so on, have high research level. 3D systems company of the United States is the first to put forward the “quick casting” rapid precision casting technology. After more than 20 years of rapid development, the rapid casting development in China has also made remarkable achievements, such as the famous Beijing Longyuan company, Xi’an Jiaotong University, Tsinghua University, Shandong University, etc. can independently master the rapid prototyping technology. With the continuous progress of science and technology in China, rapid casting technology has been put into use in aviation, instrument, machinery, automobile and other industries. However, due to the late development of rapid prototyping technology and the relatively backward level of foundry technology, its rapid sand casting technology also needs further development and research.