Chapter 1: The Basic Process Flow of Resin Sand Casting

Resin sand casting is a popular method for creating metal parts and components. The process involves several steps as you’ve mentioned:

- Mold Preparation: A pattern, which is a replica of the desired part, is placed in sand to create a mold cavity. The pattern is usually made from wood, plastic, or metal.

- Resin Sand Preparation: Sand is mixed with a resin binder to create the mold material. The resin helps hold the sand particles together and provides stability during the casting process.

- Filling: The resin sand mixture is packed around the pattern to create the mold. Proper compaction is important to ensure a detailed and accurate mold cavity.

- Hardening: The resin in the sand mixture is typically cured or hardened using various methods, such as heating or using chemical catalysts. This step gives the mold enough strength to withstand the molten metal.

- Demolding: Once the mold has sufficiently hardened, the pattern is removed from the sand, leaving behind the mold cavity.

- Cooling: If needed, the mold may be cooled to ensure that it can handle the temperature of the molten metal without deforming or cracking.

- Pouring and Solidification: The molten metal is poured into the mold cavity through a gating system. The metal then cools and solidifies within the mold to take the shape of the desired part.

- Shakeout and Cleaning: After the metal has solidified, the mold is broken apart to reveal the cast part. The cast part may have excess sand and other materials attached to it, which are removed through various cleaning methods.

- Finishing: The cast part may undergo additional processes such as trimming, grinding, and machining to achieve the final desired shape, surface finish, and dimensions.

- Quality Inspection: The final cast part is inspected for any defects or imperfections. This can include dimensional checks, visual inspections, and various non-destructive testing methods.

Resin sand casting is known for its versatility, as it can produce intricate shapes and is suitable for both small and large-scale production. The quality of the final cast part depends on factors like the quality of the mold, the casting process, and the metal used.

Chapter 2: Furan Resin Sand Casting

Furan resin sand has many advantages, such as good fluidity, good collapsibility, high production efficiency, smooth surface of sand mold castings and high dimensional accuracy, but it also has insurmountable disadvantages: high thermal expansion rate of sand core and sand mold, poor concession, poor heat dissipation, serious sulfur infiltration, etc. these disadvantages are very easy to lead to thermal cracks, especially in the production of steel castings with thin wall, excessive change of wall thickness and many hot joints, Shortcomings will be infinitely magnified and even cannot be solved.

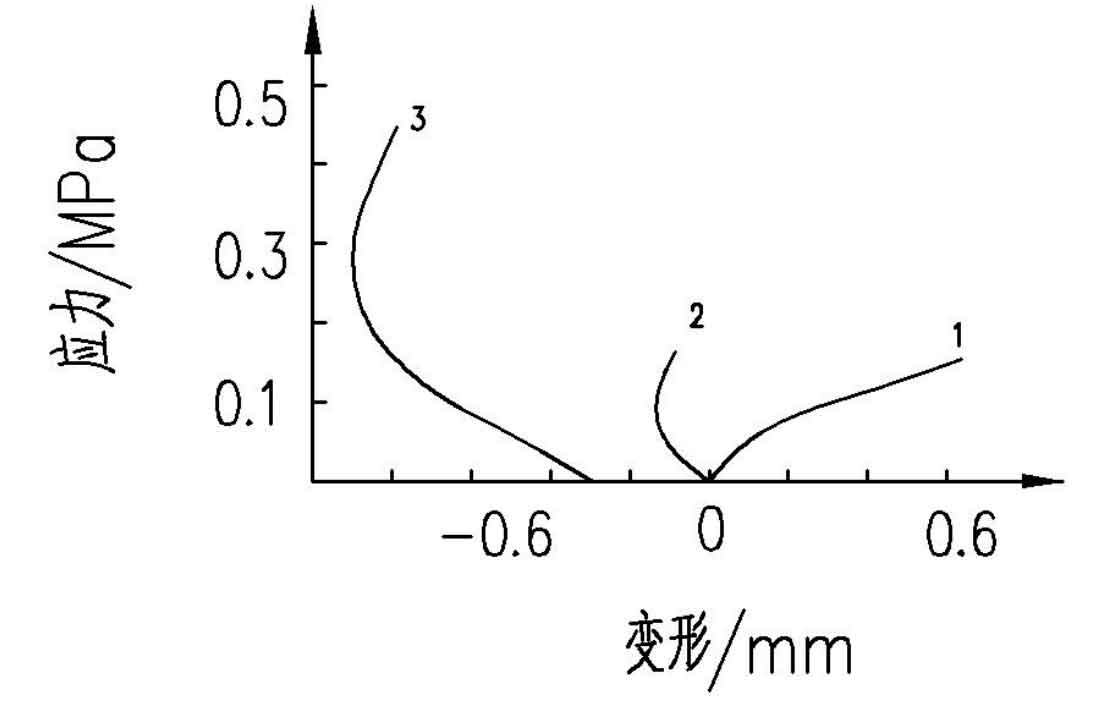

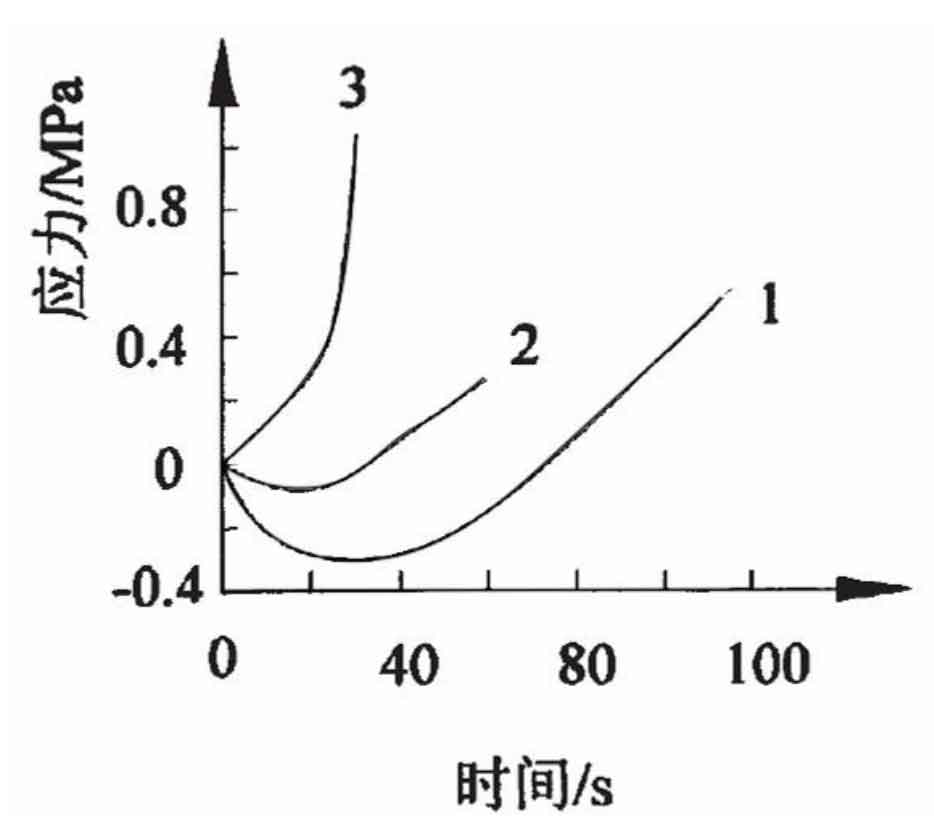

Resin sand has very good fluidity, easy compaction, small amount of resin, thin adhesive film coated on sand particles. When sand particles are heated and expanded, the thermal expansion rate of sand core and sand mold is much higher than that of other sand molds, and the thermal expansion is about twice that of carbon dioxide hardened sodium silicate sand mold, From the high temperature stress-strain curve of sand mold in Figure 1 (curve 3 represents the high temperature stress-strain curve of furan resin sand, and curve 1 represents the high temperature stress-strain curve of sodium silicate sand) and the high temperature strain time curve in Figure 2 (curve 1 represents the high temperature strain time curve of furan resin sand, and curve 3 represents the high temperature strain time curve of sodium silicate sand): the large negative deformation in Figure 1 indicates the large thermal expansion coefficient of molding sand, It will increase the resistance of sand castings during solidification shrinkage; The large amount of positive deformation and the large plastic deformation caused by the softening of molding sand at high temperature show that the yield of molding sand is very good and the shrinkage resistance to sand castings is small; The sand mold strain time curve shows that the heating loading time experienced by the sample from the beginning of heating load to breaking is also called the high-temperature endurance time of molding sand. The long high-temperature endurance time indicates that the thermal decomposition of molding sand binder is slow, the loss rate of molding sand strength is slow, and the yield of molding sand is poor. On the contrary, the earlier the high-temperature strength is lost, the better the concession of molding sand is, and the more conducive it is to reduce the hot cracking tendency of sand castings. It can be seen from Figure 1 that the furan resin sand has the largest negative deformation, while the sodium silicate sand has almost no negative deformation. It can be seen from Figure 2 that the strain time of sodium silicate sand is only more than ten seconds, while the strain time of furan resin sand lasts for two minutes.

After the molten steel is poured into the mold cavity, the high temperature will heat the resin sand. At the initial stage of the core being heated, the resin will carbonize and coke to form a hard coke skeleton, which can greatly improve the thermal strength of the sand core and seriously hinder the retreat of the sand core (mold). In addition, the higher the content of furfural alcohol in furan resin (the lower the nitrogen content), the greater the hot cracking tendency of sand castings, because furfural alcohol increases the thermal decomposition temperature of resin and reduces the thermal decomposition rate of resin, thus reducing the collapsibility of sand mold or sand core, making the sand mold or sand core more hinder the shrinkage of sand castings, resulting in an increase in the hot cracking tendency of sand castings. The curing agents used in furan resin sand casting process are dimethylbenzenesulfonic acid and p-toluenesulfonic acid, which decompose into H2S, S02, S03 and other gases at high temperature. These gases are easy to react with metals during solidification of sand castings to form FES and MNS. The melting point of these sulfides is low, only 975 ℃. At the initial stage of solidification of sand castings, these sulfides are pushed around the primary grains and finally solidified at the dendrite boundary, which is easy to cause hot brittle points, Form crack origin. Liquid metal shrinkage is an important cause of casting defects such as hot crack, deformation, shrinkage cavity and shrinkage porosity.

The furan resin sand casting mold has very good thermal insulation characteristics. When the molten steel is filled with the mold, the temperature of the molten steel in the furan resin sand casting mold is higher than that of other sand molds, and the volume shrinkage rate of the sand casting is large, so more liquid is needed to supplement the shrinkage. If the process design is improper, the volume shrinkage of steel castings during solidification will not be effectively supplemented by liquid steel, and scattered micro shrinkage cavities and shrinkage porosity will appear in sand castings, which are not dense. At the same time, due to the lag solidification of small rounded corners at the hot joints of sand castings, solidification hard shells cannot be formed quickly. When the liquid steel is supplemented to other parts of sand castings, and it cannot be supplemented by liquid steel, shrinkage cracks will be formed, This is also one of the reasons why most of the cracks in the motor shell appear on the small arc at the hot joint.

Chapter 3: Introduce different types of resin sand

Resin sand is a type of molding sand that incorporates a resin binder to enhance its properties and provide better mold strength, dimensional accuracy, and surface finish in metal casting processes. There are various types of resin sand, each with its own characteristics and applications. Here are some common types of resin sand and their features:

- Phenolic Resin Sand:

- Characteristics: Phenolic resin sand is a widely used type of resin sand known for its excellent flowability, good heat resistance, and dimensional stability. It is composed of silica sand mixed with phenolic resin and a catalyst.

- Applications: Phenolic resin sand is suitable for a range of metals and alloys, including cast iron, steel, and non-ferrous metals. It is often used in automotive and heavy machinery casting due to its high mold strength and ability to handle high pouring temperatures.

- Phenolic Cold Setting Resin Sand:

- Characteristics: This type of resin sand is formulated to cure at room temperature without the need for additional heating. It offers good mold stability and dimensional accuracy.

- Applications: Phenolic cold setting resin sand is commonly used in applications where energy costs associated with heating are a concern. It finds use in producing medium-sized castings with intricate shapes and tight tolerances.

- Phenolic Hot Setting Resin Sand:

- Characteristics: Phenolic hot setting resin sand requires the application of heat to cure and set the resin binder. This type of resin sand offers improved strength and casting quality compared to cold setting alternatives.

- Applications: It is often employed for large and heavy castings that demand higher mold strength and resistance to metal penetration. Industries such as aerospace, energy, and marine may use phenolic hot setting resin sand.

- Furan Resin Sand:

- Characteristics: Furan resin sand is known for its excellent heat resistance, making it suitable for casting materials that require high pouring temperatures. It has good collapsibility, allowing easy removal of the sand after casting solidification.

- Applications: Furan resin sand is commonly used in the production of ferrous and non-ferrous castings where high thermal resistance is needed. It finds applications in industries such as automotive, aerospace, and construction.

- Alkaline Phenolic Resin Sand:

- Characteristics: Alkaline phenolic resin sand has an alkaline pH and is known for its good collapsibility and high thermal stability.

- Applications: This type of resin sand is used for producing large and complex castings, particularly those made of steel and other alloys. It is suitable for castings with intricate cores and cavities.

- Epoxy Resin Sand:

- Characteristics: Epoxy resin sand offers exceptional dimensional accuracy, low gas evolution during casting, and good resistance to moisture and humidity.

- Applications: Epoxy resin sand is commonly used in precision casting applications, including art casting, jewelry production, and the manufacturing of components for electronics and optics.

The choice of resin sand type depends on factors such as the type of metal being cast, casting size, required surface finish, casting complexity, and other specific requirements of the application. Manufacturers select the appropriate resin sand to optimize casting quality, efficiency, and cost-effectiveness.

Chapter 4: Preparation process of resin sand mold

The preparation process of resin sand molds involves several key steps to ensure the creation of high-quality molds for metal casting. Here’s an overview of the typical steps involved in preparing resin sand molds:

- Pattern or Model Production:

- The process begins with the creation of a pattern or model, which serves as a replica of the final casting shape. Patterns can be made from various materials such as wood, metal, or plastic, depending on the casting requirements and the intricacy of the design.

- Patterns are typically slightly larger than the desired final casting size to account for the contraction of the metal during solidification.

- Mold Box Preparation:

- A mold box or flask is prepared to contain the molding sand and the pattern. The mold box consists of two halves: the cope (upper half) and the drag (lower half). These halves can be made from metal, wood, or other suitable materials.

- Pattern Layout and Alignment:

- The pattern is placed within the drag portion of the mold box. It can be aligned using various alignment tools and techniques to ensure accurate positioning and proper parting line match.

- Resin Sand Coating:

- The mold cavity surfaces of both the cope and the drag are coated with a layer of resin sand mixture. This coating provides the mold with its shape and helps in reproducing fine details and surface finish.

- The resin sand mixture typically consists of silica sand and a resin binder (such as phenolic resin), along with additives that enhance flowability and curing properties.

- Mold Assembly:

- Once the sand coating is applied, the cope and drag halves of the mold box are brought together and aligned using pins or guides. The pattern remains inside, sandwiched between the two halves.

- The mold halves are then securely clamped together, creating a complete mold cavity that matches the shape of the desired casting.

- Curing:

- Depending on the type of resin sand used, the mold may require curing. Curing can involve natural air drying, accelerated drying, or heat curing in the case of some resin sand types. This step solidifies the resin binder, giving the mold strength and stability.

- Pattern Removal and Core Placement:

- After the resin sand has cured, the mold box is opened, and the pattern is removed from the drag. This leaves behind an impression of the pattern’s shape in the sand.

- If the casting design requires internal cavities or features, cores (made of sand mixed with a binder) are inserted into the mold to create these voids.

- Mold Closing and Pouring:

- The mold box is closed again, aligning the cope and drag perfectly. Molten metal is then poured into the mold through a gating system designed to facilitate smooth metal flow and minimize defects.

- Solidification and Cooling:

- The poured metal solidifies within the mold cavity. The cooling process allows the metal to take on the shape of the mold and form the final casting.

- Mold Breakout and Casting Removal:

- Once the metal has fully solidified and cooled, the mold is broken open, revealing the newly cast part. Excess sand is removed, and the casting is cleaned, finished, and sometimes subjected to additional processes like heat treatment or surface treatment.

These steps collectively form the resin sand mold preparation process, enabling the creation of accurate, well-defined, and high-quality metal castings for various industrial applications.

Chapter 5: Demolding and Cooling of Resin Sand Castings

Demolding resin sand castings after hardening and the subsequent cooling process are critical steps in the metal casting process to ensure the successful production of quality castings. Here’s a breakdown of these steps:

1. Demolding Resin Sand Castings:

Once the resin sand mold has solidified and the casting metal has cooled sufficiently, it’s time to remove the casting from the mold. The demolding process requires careful handling to avoid damaging the casting or the mold. Here’s how it’s typically done:

- Mold Box Opening: The mold box (cope and drag) is carefully opened to expose the casting. This can involve unclamping or separating the mold halves, depending on the type of mold used.

- Pattern Removal: If the casting was created using a pattern, it may be necessary to remove the pattern from the mold before attempting to remove the casting itself. This is often a delicate process to ensure that the sand mold remains intact.

- Shakeout: For some castings, the mold can be vibrated or shaken to help loosen the sand and release the casting. This can be aided by specialized equipment designed to facilitate the process without damaging the casting.

- Knockout: In more complex or intricate molds, a process called knockout is used. This involves carefully breaking away the sand mold to expose the casting. Knockout equipment and tools are designed to minimize damage to the casting and maximize the reusability of the sand.

- Cleaning: After the casting is removed from the mold, excess sand, residual binder, and any other debris are cleaned off the casting’s surface. This might involve brushing, sandblasting, or other cleaning techniques.

2. Cooling Castings in the Mold:

The cooling process is critical to allow the casting to solidify fully and achieve its desired properties. Cooling too rapidly can lead to defects, while cooling too slowly can cause issues with the metal’s microstructure. Here’s how cooling is managed:

- Natural Cooling: After pouring the molten metal into the mold, the metal begins to cool naturally. The mold’s material and design can influence the rate of cooling. Insulating materials might be used to control the cooling rate.

- Mold Material: Different mold materials (such as sand, metal, or ceramic) have varying thermal conductivity. This can influence how quickly the casting cools and solidifies. The mold’s heat capacity can also influence cooling.

- Cooling Rate Control: In some cases, controlled cooling methods are used, such as air cooling or water quenching, to achieve specific material properties. These methods are used with caution to prevent cracking or other defects due to rapid cooling.

- Heat Treatments: Depending on the casting material and application, heat treatments may be applied after the casting is removed from the mold. Heat treatments can refine the material’s microstructure and enhance its mechanical properties.

Properly managing the demolding and cooling processes is crucial to achieving high-quality castings with the desired properties. Careful handling, attention to detail, and adherence to best practices in the casting industry play a significant role in producing successful castings.

Chapter 6: The Widespread Application of Resin Sand Castings

Resin sand castings find wide application across various industries due to their ability to produce complex shapes, high dimensional accuracy, and good surface finish. Here are some of the fields where resin sand castings are widely used:

- Automotive Manufacturing: Resin sand castings are extensively used in the automotive industry for manufacturing engine components, transmission parts, chassis components, and other critical parts. Their ability to produce intricate shapes and maintain tight tolerances makes them suitable for a range of automotive applications.

- Mechanical Engineering: Resin sand castings play a vital role in mechanical engineering applications, where precision and strength are crucial. Components such as pumps, valves, gears, and various machine parts are often produced using resin sand casting due to their ability to reproduce intricate features.

- Energy and Power Generation: In the energy sector, resin sand castings are used to produce components for power generation equipment, including turbines, generators, and various parts for renewable energy systems. The casting process allows for the creation of durable and reliable components needed for efficient energy production.

- Aerospace and Aviation: Resin sand castings are utilized in the aerospace industry to manufacture critical components like engine parts, landing gear components, and structural elements. The casting process’s precision and ability to produce complex shapes align well with the demands of aerospace engineering.

- Heavy Machinery and Equipment: Various heavy machinery and equipment, such as construction machinery, mining equipment, and agricultural machinery, require robust components. Resin sand castings provide the necessary strength and durability for these applications.

- Pumps and Compressors: Resin sand castings are commonly used in the production of pump and compressor components, including casings, impellers, and housings. The casting process enables the creation of intricate internal geometries necessary for efficient fluid and gas handling.

- Railway and Transportation: The railway and transportation industries utilize resin sand castings for manufacturing components like train brake systems, couplings, and structural elements. These castings provide the required mechanical properties and dimensional accuracy.

- Marine and Shipbuilding: In the marine sector, resin sand castings are employed to produce various ship components, such as propellers, engine parts, and structural elements. The castings’ ability to withstand harsh marine environments is beneficial for these applications.

- Oil and Gas Industry: Resin sand castings are used to create components for the oil and gas sector, including valves, pipe fittings, and machinery parts. The casting process allows for the production of components that can withstand the demanding conditions of oil and gas extraction.

- Industrial Equipment: Resin sand castings are widely used in the manufacturing of industrial equipment, including pumps, valves, rollers, and housings. The ability to tailor the castings to specific performance requirements is valuable in this sector.

The versatility of resin sand castings makes them suitable for a broad spectrum of industries, enabling the production of diverse components that contribute to various technological advancements and industrial processes.

Chapter 7: The Advantages and Disadvantages of Resin Sand Castings

Resin sand castings offer several advantages, including high precision and good surface quality. However, they also come with certain disadvantages, such as longer production cycles and higher costs. Let’s explore these points in more detail:

Advantages of Resin Sand Castings:

- High Precision: Resin sand castings can achieve excellent dimensional accuracy and reproduce intricate details, making them suitable for producing complex parts with precise specifications.

- Good Surface Quality: The casting process using resin sand molds results in smoother surface finishes on the cast parts, reducing the need for extensive post-processing and finishing.

- Complex Geometries: Resin sand castings can accommodate intricate shapes and complex internal features, enabling the production of parts with varying wall thicknesses and intricate designs.

- Reduced Defects: The use of resin sand molds can minimize common casting defects such as sand inclusions and porosity due to the improved control over the molding process.

- Material Versatility: Resin sand casting can work with a wide range of metals and alloys, including ferrous and non-ferrous materials, enabling flexibility in material selection.

Disadvantages of Resin Sand Castings:

- Longer Production Cycles: The preparation of resin sand molds, including pattern making, coating, curing, and mold assembly, can be time-consuming, leading to longer production cycles compared to other casting methods.

- Higher Costs: The additional steps involved in resin sand casting, such as pattern creation, sand coating, and curing, contribute to higher production costs compared to simpler casting methods.

- Labor-Intensive: The resin sand casting process requires skilled labor for pattern making, mold preparation, and other steps, contributing to higher labor costs.

- Limited Production Rates: The time-consuming nature of the resin sand casting process can limit the overall production rate, making it less suitable for high-volume production requirements.

- Mold Wear and Reusability: Resin sand molds can experience wear and degradation over multiple uses, affecting their dimensional accuracy and surface quality. Regular mold maintenance or replacement may be necessary.

- Environmental Considerations: The use of resin binders and curing agents can have environmental implications due to the emission of volatile organic compounds (VOCs) during the curing process.

In summary, resin sand castings offer advantages in terms of precision, surface quality, and the ability to produce complex parts. However, the longer production cycles, higher costs, and other limitations associated with the process should be carefully considered when selecting casting methods for specific applications. The choice between resin sand casting and other casting methods depends on the balance between the desired part characteristics, production volume, and economic factors.

Chapter 8: The Quality Control of Resin Sand Castings

Quality control is a crucial aspect of resin sand casting to ensure that the castings meet the required specifications and standards. Effective quality control helps identify and address issues early in the process, resulting in higher-quality finished products. Here are some key steps and considerations for quality control in resin sand castings:

- Material Inspection:

- Start by inspecting the quality of the raw materials, including the sand, resin binder, curing agents, and additives. Ensure that they meet the required specifications and are free from contaminants.

- Pattern and Mold Inspection:

- Check the pattern for any defects, warping, or inaccuracies that might affect the final casting. Inspect the mold cavity surfaces for proper coating, uniformity, and absence of defects.

- Process Parameters:

- Monitor and control the resin mixing ratios, sand compaction, curing time, and temperature during mold preparation to ensure consistency and uniformity in mold quality.

- Casting Design and Feasibility:

- Evaluate the casting design for moldability, taking into account factors such as draft angles, undercuts, and parting lines. Adjust the design if necessary to ensure successful casting.

- Visual Inspection:

- Regularly inspect the castings visually for surface defects, such as cracks, porosity, sand inclusions, and other irregularities. Address any issues promptly.

- Dimensional Inspection:

- Measure the castings’ dimensions and tolerances using appropriate inspection tools, such as calipers, micrometers, and gauges. Compare the measurements to the specified requirements.

- Non-Destructive Testing (NDT):

- Implement NDT techniques like X-ray, ultrasound, or dye penetrant testing to detect internal defects that may not be visible through visual inspection.

- Casting Weight and Composition:

- Monitor the casting weight to ensure consistency and compliance with specifications. Perform periodic chemical composition analysis to verify the alloy composition.

- Heat Treatment Verification:

- If heat treatment is part of the process, verify that the specified heat treatment cycles are followed correctly to achieve the desired material properties.

- Testing for Mechanical Properties:

- Perform tests such as hardness testing, tensile testing, and impact testing to evaluate the mechanical properties of the castings and ensure they meet required standards.

- Documentation and Traceability:

- Maintain detailed records of each casting’s manufacturing process, inspection results, and any corrective actions taken. This documentation helps ensure traceability and accountability.

- Continuous Improvement:

- Establish a feedback loop to collect data on defects, rejections, and any quality issues. Use this information to identify root causes, implement corrective actions, and continuously improve the casting process.

By implementing a comprehensive quality control process, manufacturers can minimize defects, improve product consistency, and deliver resin sand castings that meet or exceed customer expectations and industry standards.

Chapter 9: The Impact of Resin Sand Casting on the Environment

The resin sand casting process, like many industrial processes, can have various environmental impacts. These impacts can include the generation of waste, energy consumption, emissions of volatile organic compounds (VOCs), and the consumption of natural resources. However, there are several improvement measures and sustainability considerations that can help mitigate these impacts. Here’s a breakdown:

Environmental Impacts:

- Waste Generation: The resin sand casting process can generate waste in the form of used sand, resin-coated sand scraps, and other byproducts.

- Energy Consumption: The process requires energy for various stages such as sand mixing, mold curing, and metal melting.

- Volatile Organic Compounds (VOCs): During the resin curing process, volatile organic compounds are emitted, contributing to air pollution.

- Water Usage: Water might be used for cooling and in the sand preparation process.

- Greenhouse Gas Emissions: Energy consumption and combustion processes during metal melting contribute to greenhouse gas emissions.

Improvement Measures and Sustainability Considerations:

- Material Efficiency:

- Optimize sand usage and minimize waste generation by implementing efficient sand reclamation systems.

- Explore the use of environmentally friendly binder systems that produce fewer emissions during curing.

- Energy Efficiency:

- Invest in energy-efficient equipment and technologies to reduce energy consumption throughout the casting process.

- Consider using renewable energy sources, such as solar or wind power, to power parts of the process.

- Emission Reduction:

- Implement VOC capture and control systems during the curing process to reduce emissions.

- Use low-emission resins and binders to minimize VOC emissions.

- Waste Management:

- Develop strategies for reusing or recycling waste materials, such as used sand and sand-coated scraps, to minimize landfill disposal.

- Water Conservation:

- Implement water recycling and reuse systems to minimize water consumption during the casting process.

- Green Design:

- Design castings with minimal material waste and consider part consolidation to reduce the number of castings required.

- Lifecycle Assessment:

- Conduct a lifecycle assessment to identify hotspots of environmental impact and prioritize improvement areas.

- Sustainable Materials:

- Explore the use of alternative, more sustainable binders and resins that have lower environmental impacts.

- Regulatory Compliance:

- Stay updated with environmental regulations and ensure compliance to minimize negative impacts.

- Employee Training:

- Provide training to employees on environmental best practices and the importance of minimizing waste and emissions.

- Certifications and Labels:

- Consider obtaining certifications or labels that signify environmentally friendly practices and products.

By implementing these improvement measures and considering sustainability factors, resin sand casting processes can be made more environmentally responsible, reducing their overall impact on natural resources, energy consumption, and emissions. This contributes to a more sustainable manufacturing process and aligns with growing societal and regulatory expectations for environmentally conscious production methods.

Chapter 10: The Future Development Direction of Resin Sand Casting Technology

The future development of resin sand casting technology is likely to be shaped by advancements in materials, digital manufacturing technologies, and sustainability considerations. Here are some potential directions for the evolution of resin sand casting:

- Advanced Binder Systems:

- Research and development will focus on creating more environmentally friendly binder systems that reduce emissions and waste during the curing process.

- New binders with improved properties, such as lower VOC emissions, faster curing times, and enhanced mechanical performance, will enhance the casting process.

- Digital Manufacturing and Simulation:

- Digital twin technology will become more integral, enabling virtual testing and optimization of casting processes before physical production.

- Simulation tools will play a critical role in predicting defects, optimizing gating and riser design, and ensuring high-quality castings.

- Additive Manufacturing Integration:

- Combining resin sand casting with additive manufacturing (3D printing) can lead to more efficient and precise mold production.

- Additive techniques might be used for producing intricate cores or patterns, reducing the need for complex tooling.

- Material Innovations:

- Development of new alloys and composite materials optimized for resin sand casting will lead to improved performance and lighter components.

- Sustainable materials that reduce environmental impact while maintaining quality will gain importance.

- Smart Manufacturing:

- Sensor integration and real-time monitoring will enhance process control, leading to reduced defects and optimized resource utilization.

- Predictive maintenance tools will help prevent unexpected downtime and optimize equipment performance.

- Robotics and Automation:

- Automation will increase efficiency by handling repetitive tasks like sand mixing, mold assembly, and finishing processes.

- Robots and automated systems will improve consistency and reduce labor-intensive steps.

- Hybrid Casting Technologies:

- Combining different casting methods (e.g., resin sand casting with investment casting) can result in improved part quality and reduced production times.

- Sustainability Focus:

- Environmental considerations will drive the adoption of cleaner production practices, such as using more sustainable binders, reducing energy consumption, and minimizing waste generation.

- Customization and Complexity:

- Resin sand casting will become more adaptable to producing small batches of complex parts, catering to industries that require customization.

- Training and Skilled Labor:

- Training programs will focus on equipping the workforce with skills in digital manufacturing, simulation, and operating advanced machinery.

- Global Collaboration:

- Collaboration among researchers, manufacturers, and industry associations will accelerate the pace of innovation, leading to shared best practices and standards.

As industries demand higher quality, faster production, and greater sustainability, the future of resin sand casting technology will be driven by a combination of novel materials, digital tools, and efficient manufacturing practices. The integration of these advancements will contribute to the growth of resin sand casting as a competitive and sustainable manufacturing method.