Under the background of “China Intelligent Manufacturing 2025”, the integration of modern technology into the traditional casting industry is a scientific way to realize the intelligent production transformation of end cover castings. With the modernization process, reverse engineering has become more mature, bringing different options for part modification and design. The 3D printing technology of additive manufacturing is also becoming more and more popular in the pursuit of customized production. Therefore, more green and intelligent production methods are also derived.

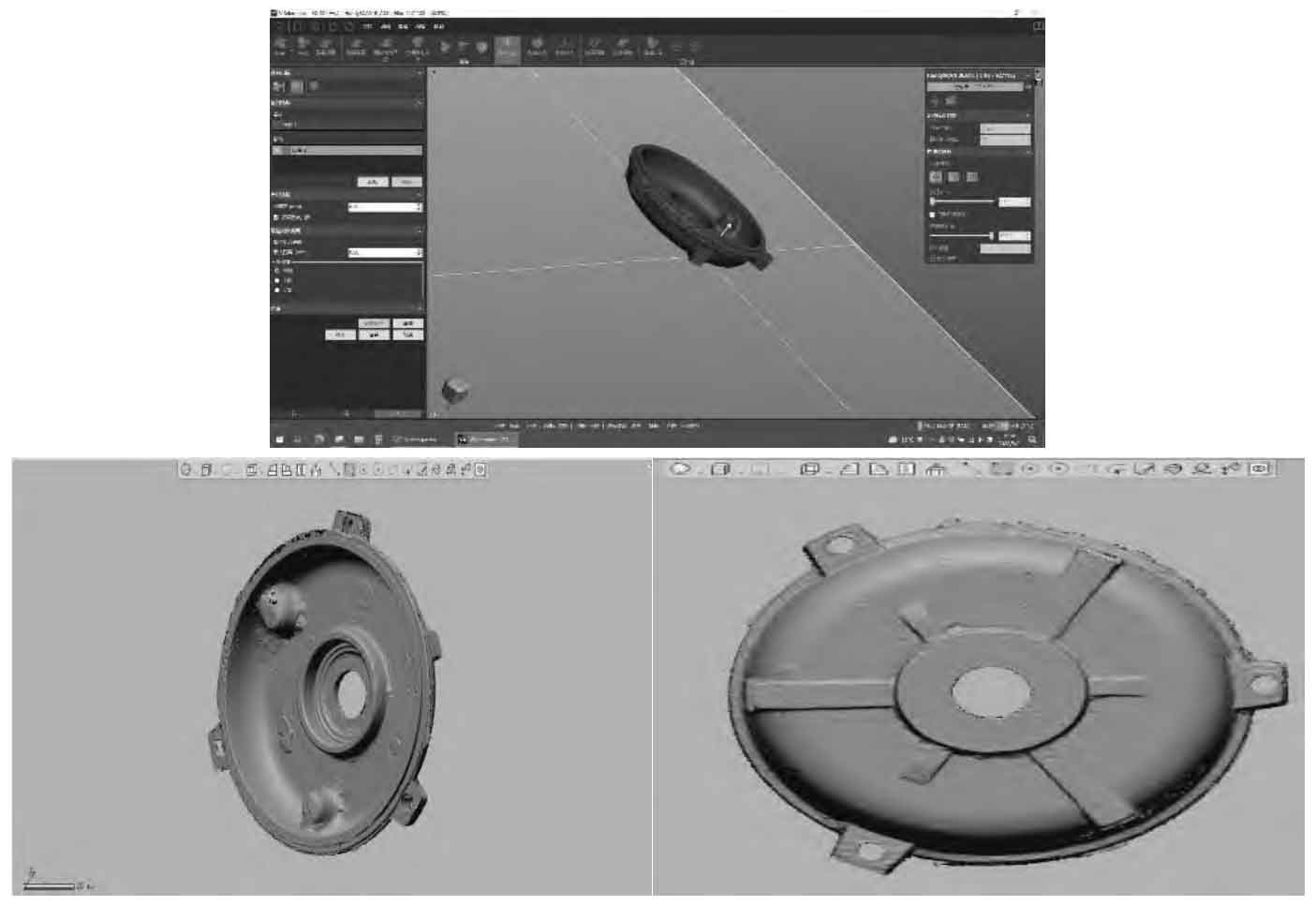

The traditional casting process is divided into parts for casting production. The main process is part modification – casting process design – casting tooling production – casting production. The designers are required to have a certain understanding of the whole production technology, with large staff flow and long production cycle. Using reverse engineering and 3D printing technology for production, each process can be simplified, end cover casting model reconstruction – casting process design – sand mold 3D printing – pouring cleaning. Compared with traditional casting, it is more friendly to use reverse engineering to reconstruct the part model to repair and modify the model that has lost the original data, and also to speed up the paperless production process. The use of sand 3D printing technology not only saves the process of designing and manufacturing casting tooling, but also saves the selection of parting surface design, sand core design, draft angle and other parameters in casting process design, greatly reducing the cost of process design and manufacturing tooling. Due to the need for professional equipment for production, the advantages in customized production and single and small batch production are more prominent. Let’s take the production of end cover as an example.

The most important feature is the use of reverse engineering for model reconstruction, which plays an important role in the repair and modification of parts without data. The sand 3D printing technology is adopted to shorten the cycle required for single piece, small batch production and the first batch of parts, and effectively control the cost. The scheme proposed in this paper can be used separately to simplify the casting process, which meets the modern requirements of resource saving, efficient production and green production, and has guiding significance for the construction of intelligent production lines.