In the lost foam casting process of nodular cast iron, in addition to the treatment temperature of molten iron and the amount of nodulizing agent, the geometric dimension of the casting is also another important factor affecting its microstructure. In general, the wall thickness of each part of the casting is uneven.

The different wall thickness of the casting results in different solidification rates at various parts, resulting in great differences in the microstructure and mechanical properties of the materials at various parts of the casting. In addition, the casting internal stress will be generated between the internal structures of the casting, which is unfavorable to the performance of the casting. In addition, in the parts with large wall thickness, the microstructure of the alloy is coarse and the mechanical properties are poor. In order to refine the structure of castings, the method of optimizing the structure of castings is usually used. Among them, the wall thickness of the casting is one of the important indexes for the optimal design of the casting structure.

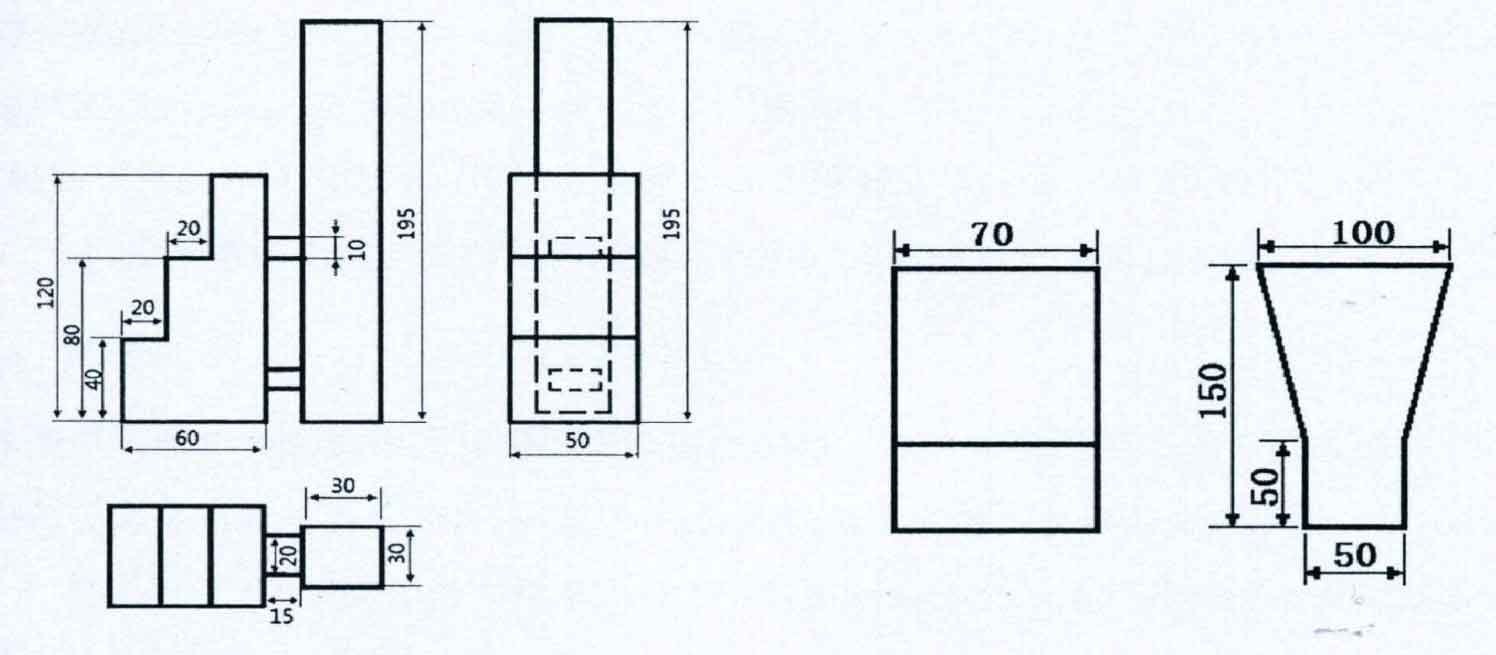

The ladder shaped sample as shown in the figure is adopted, and its sample structure and geometric dimensions are shown in the figure. The melting materials are cast pig iron, Q235 steel and 75 ferrosilicon, in which the weight ratio of cast pig iron to Q235 steel is 8:2. Inoculation and spheroidizing treatment are carried out in the ladle. The addition amount of spheroidizing agent and inoculant is 1.4% and 0.4% of the burden weight respectively. After pouring, the samples were ground and polished, the graphite morphology was observed by optical microscope, and the matrix was corroded by 2% nitric acid alcohol solution for metallographic observation. The effect of sample wall thickness on the graphite morphology and matrix structure of nodular cast iron was studied.