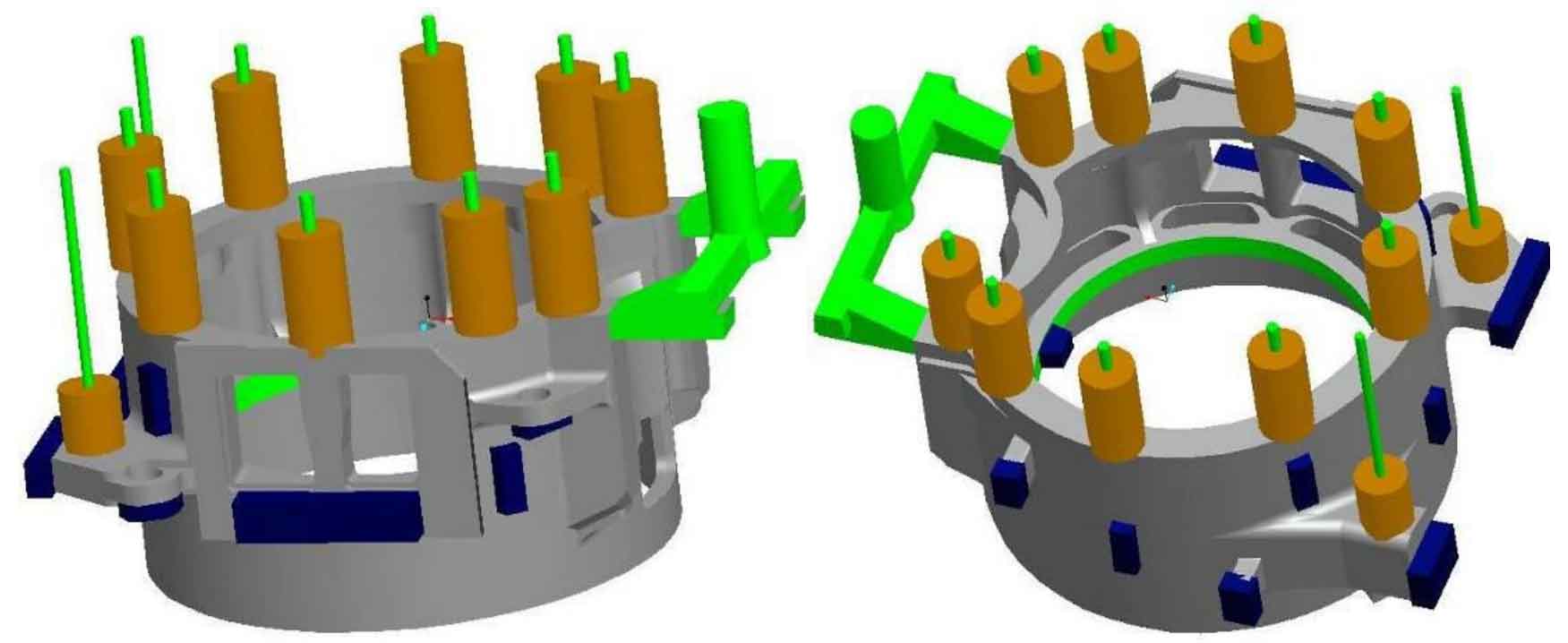

① Sand casting process scheme

The sand casting process scheme adopts the top pouring system. All the workpieces are in the lower box, and the upper box only contains the processing quantity and pouring risers. 11 risers are placed at the thick part of the upper box for feeding, and different types of cold iron are added at the hot joint and thick position, which basically conforms to the principle of sequential solidification. The process diagram is shown in Figure 1.

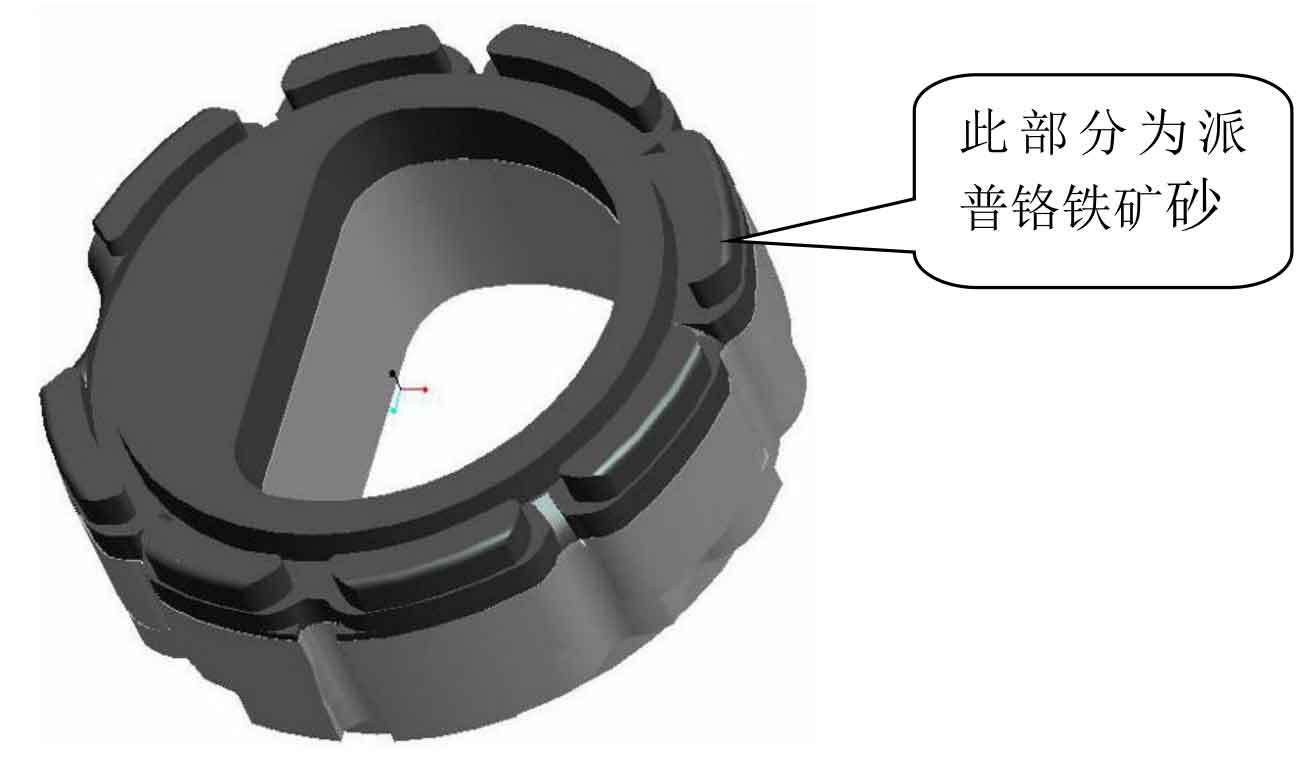

② Sand mold and sand core process

Main sand core process: the part with the thickness of 40-50mm below the circumference of the middle main sand core ring belt is embedded with PAP chromite sand, and the rest is made of furan resin sand, as shown in Figure 2.

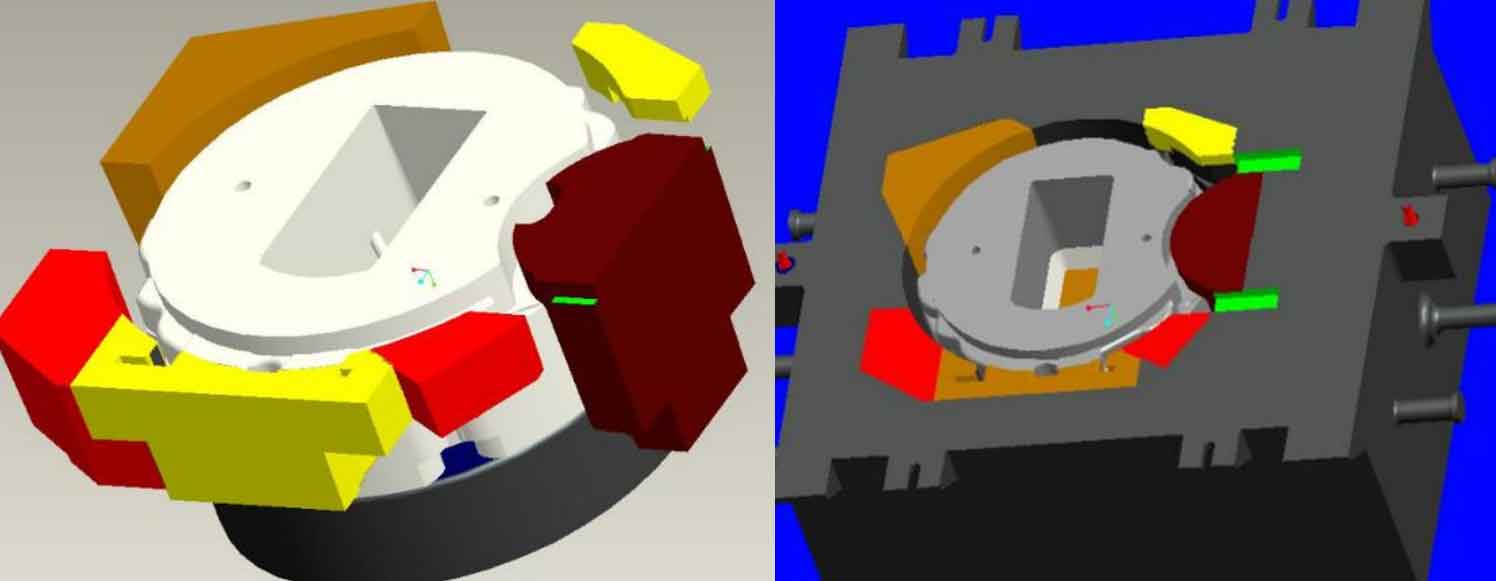

Appearance and other sand molding processes: the shape and other sand cores are all molded with furan resin sand, as shown in Figure 3.