(1) Modulus calculation

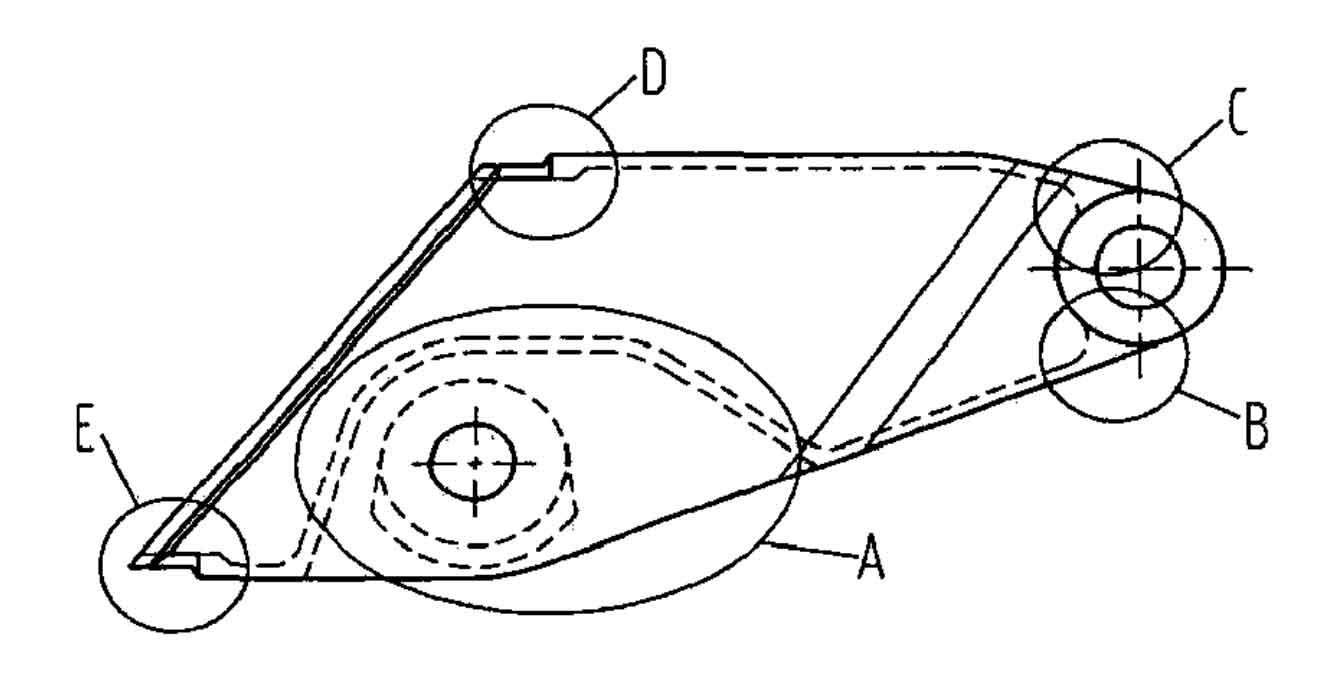

To calculate and design the riser, first analyze the product structure and calculate the modulus of thick and large area. After analyzing the structure of sand castings, confirm that the distribution of thick areas of products is shown in Fig. 1.

It can be seen from the figure that there are 5 relatively thick areas in the whole sand mold casting.

The plate wall thickness in area a is 53mm, and there are bosses and holes. The modulus method is used for calculation, and the modulus Ma of sand castings in this area is 2.53.

B. Area C is a non-standard structure, which is calculated by modulus method. The modulus MB and MC of sand castings in both areas are 2.52.

D. Area E is a thin-walled connection area. Compared with the adjacent areas, the wall thickness is thicker. The modulus method is used for calculation, and the modulus MD and me are 1.22.

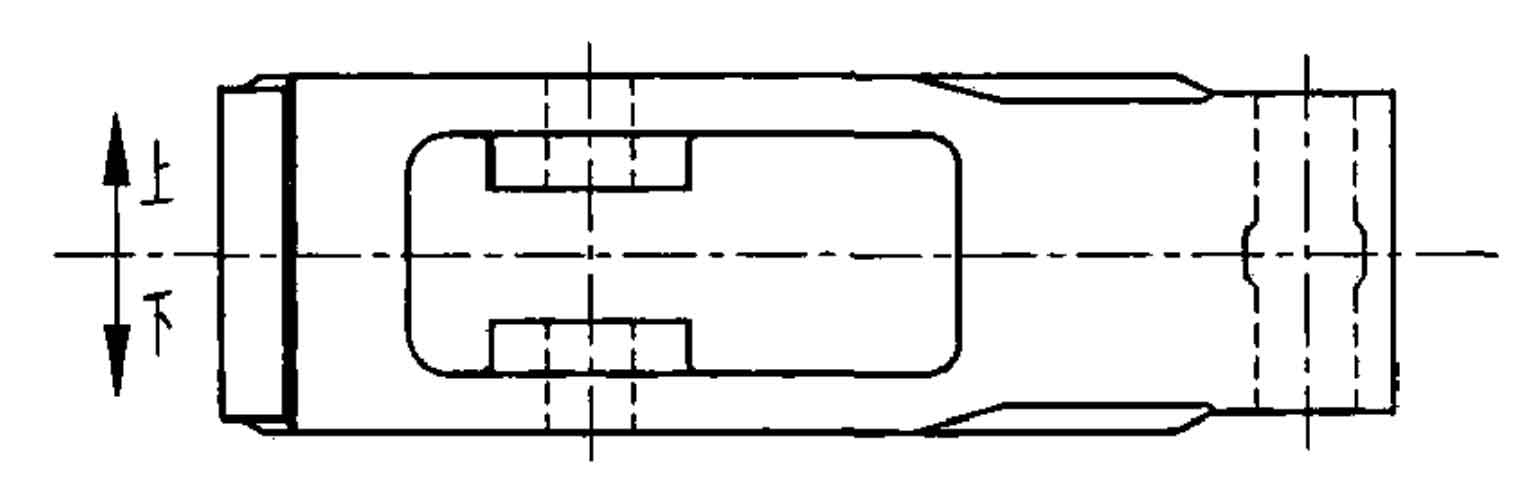

(2) Determination of parting surface

The parting surface of sand casting refers to the joint surface between each component of the mold. Reasonable selection of parting surface can reduce the difficulty of process design, simplify sand casting process, improve process yield and reduce production cost.

According to the structure of product k141, the parting surface is set, as shown in Figure 2. This parting is convenient to set the top riser and reduce the side riser, which is conducive to the sequential solidification and the positioning of the sand core.

(3) Riser design

Calculate the riser of sand mold casting according to the modulus method in the reference book. The modulus amplification factor F is 1.2 for the open riser and 1.1 for the top concealed riser.

| Hot spot area | Casting modulus | Number of risers | Modulus theoretical magnification | Modulus actual magnification | Riser modulus | Riser size (model) | Internal quality assurance measures |

| A | 2.53 | 3 | 1.1 | 1.11 | 2.80 | 10/13K | Top riser feeding |

| B | 2.52 | 1 | — | — | — | — | External chill |

| C | 2.52 | 1 | 1.2 | 1.25 | 3.15 | Φ150X300 | Side riser feeding |

| D | 1.22 | 1 | 1.2 | 1.72 | 2.10 | Φ100X200 | Side riser feeding |

| E | 1.22 | 0 | — | — | — | — | External chill |

According to the modulus calculation results and the design of parting surface, the riser of sand mold casting is selected, as shown in the table. After the modulus of area C is enlarged by 1.2 times, the standard side riser in the reference book is not fully suitable, so the riser with modulus of 1.25 times is selected. The modulus of area D is actually enlarged by 1.72 times in order to improve the feeding range.

(4) Cold iron design

Areas B and e shown in Figure 1 need to place external cooling iron for quenching.

In production practice, the casting modulus with 1-2 times the thickness of cold iron is generally taken. When the thickness of the chill is equal to the thickness of the quenched casting, it is conducive to eliminate the influence of accidental overheating, especially when the sprue is set at the part of the chill.

Two 60mmx60mmxl00mm external cold irons are set in area B, two 20mmx20mmxll5mm external cold irons are set at the side of area E, and one 60mmx40mmx25mm external cold iron is set at the bottom of area E.