1. Casting analysis and selection of sand casting process

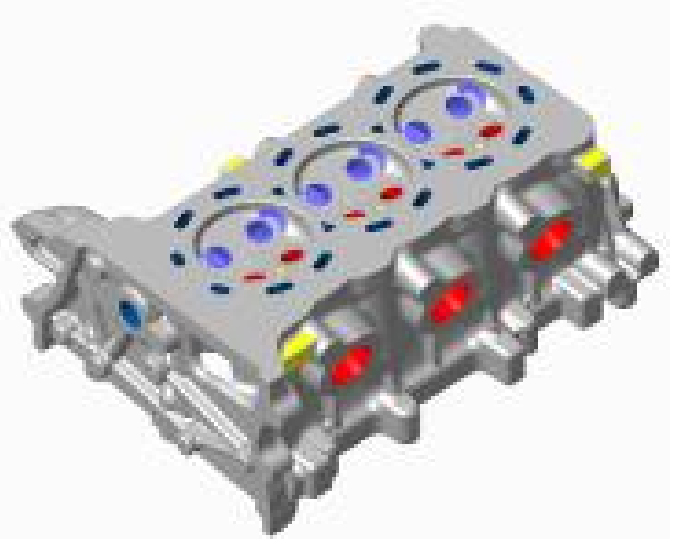

As shown in Figure 1, the cylinder head of passenger car 3-cylinder 4-Valve engine is shown. The sand casting material is alsi10mgcu, and the outline dimension of sand casting is 360mm × 180mm × 123mm, the blank weight of sand casting is 10.8kg, and the general wall thickness is 4.5mm. Sand castings have complex internal structures such as water jacket, air inlet, exhaust and oil channel, so sand mold core assembly gravity pouring process is selected in the trial production stage.

2. Design of gating system and process parameters

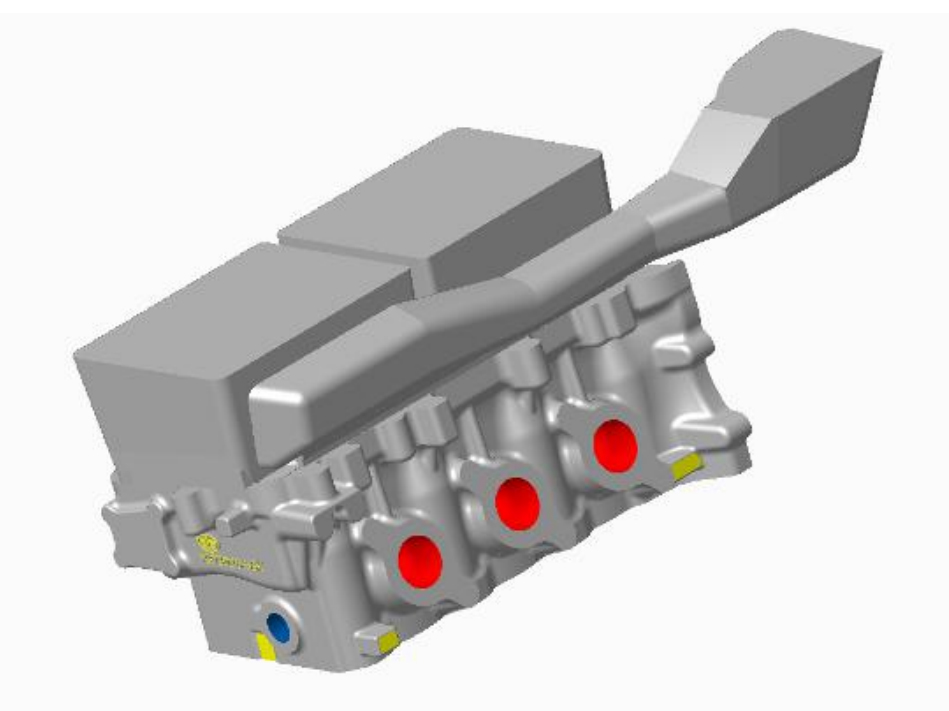

According to the structural characteristics and casting requirements of sand castings, the pouring direction of the cylinder head is that the top surface of the cylinder is facing down, and the pouring mode of top injection is adopted. Combined with experience and theoretical calculation, a single side long strip inner gate is designed, and a larger open riser is designed at the upper end for feeding, exhaust and scum of sand castings. The specific gating system process is shown in Figure 2. The pouring temperature of sand castings is 725 ~ 735 ℃.