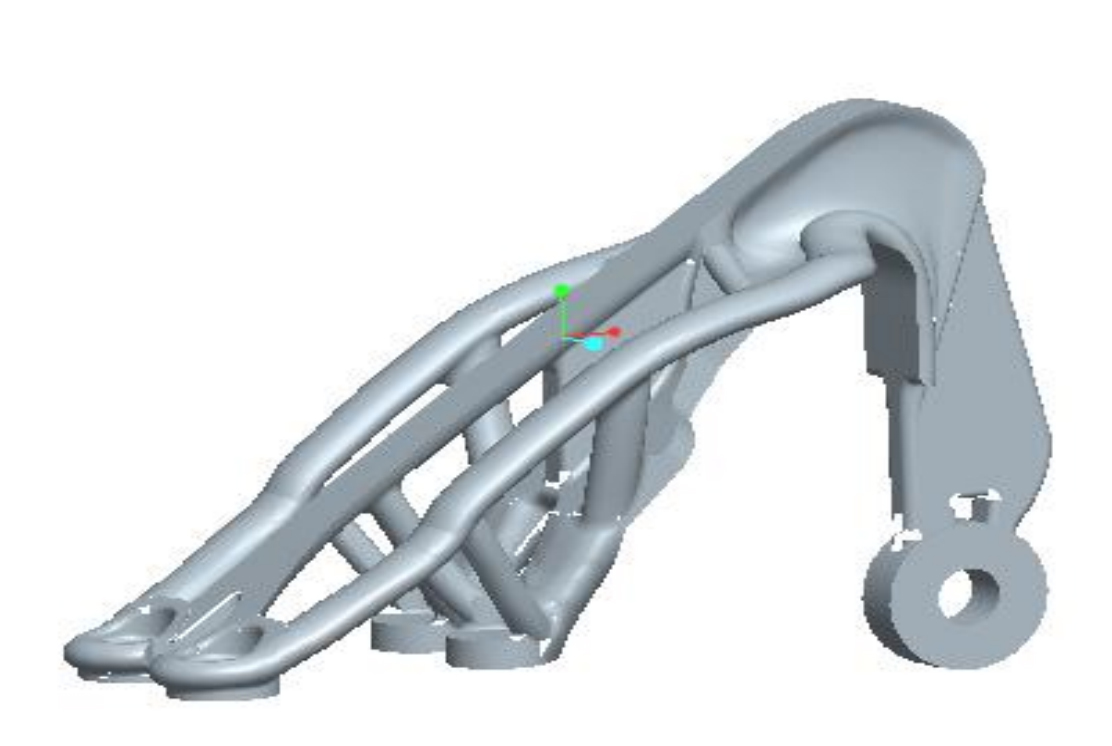

The mechanical parts of topology design must have good manufacturability before the products have practical value. The product of topological design of investment casting bearing support is shown in Figure 1, and the overall size is 122.42mmx80 68mmX42. 52mm, the minimum wall thickness is 3mm, and there are four threaded holes with a diameter of 5mm at the bottom, which need to be formed by subsequent machining. Because of its complex structure, traditional machining is difficult to form. It is a typical ric part, which is conducive to give full play to the advantages of ric.

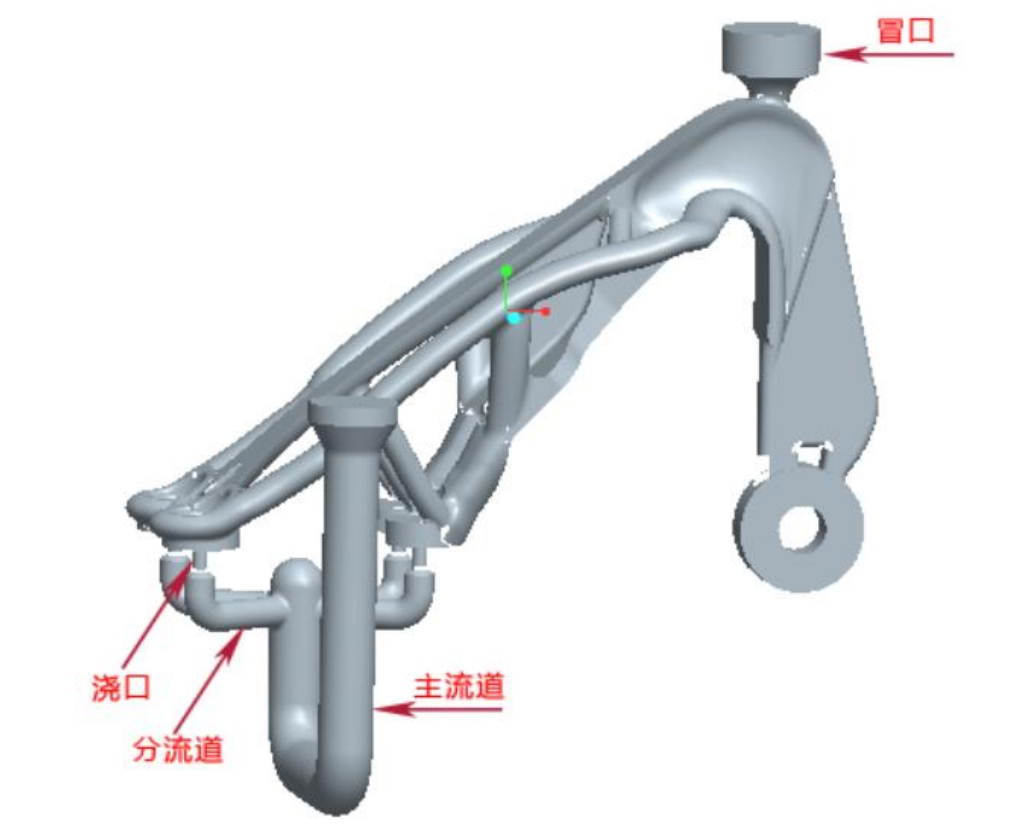

(1) The design principles of gating system are as follows:

The bearing support has the characteristics of small size, thin wall and complex structure. Therefore, in order to make the liquid metal fill the mold smoothly and avoid the impact on the mold shell wall, the bottom pouring method is selected; At the same time, in order to complete the mold filling, reduce the volume of shrinkage cavity and porosity and improve the quality of investment casting, a riser is set at the last solidification part.

The gate is set at the thread position where the investment casting is finally solidified and needs machining. In order to ensure stable mold filling, the number of internal gates and the number of threaded holes are the same, and the diameter and cross-sectional area of the internal gate have a certain proportional relationship with the diameter and cross-sectional area of the hot node circle at the final solidification. The diameter and length of the internal gate are preliminarily determined to be 6mm and 4mm through the comparative coefficient method. Adopt the gating system design of s straight > s cross > s inside, that is, the sectional area of the sprue is greater than that of the cross sprue and greater than that of the inner sprue. Provide the longitudinal temperature gradient to form a good feeding for the investment casting. The diameter of the sprue is 9mm, the length is 20mm, the diameter of the sprue is 15mm and the length is 140mm.

According to the above principles, the pouring system of bearing support is shown in Figure 2 below.

(2) Pouring parameter selection

The casting temperature should be 1550-100 ℃ for the casting of thin-wall parts, so the initial casting temperature should be higher than that of the casting of thin-wall parts.

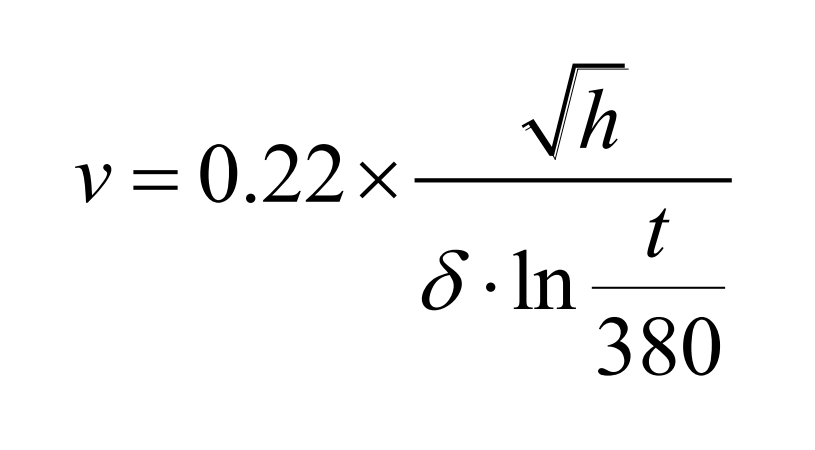

Pouring speed selection: the pouring speed can be calculated according to kalkin formula:

In the formula, H – height of investment casting; δ – Wall thickness of investment casting; T – pouring temperature of alloy; According to the comprehensive calculation results, the pouring speed is preliminarily determined as 30mm / s.

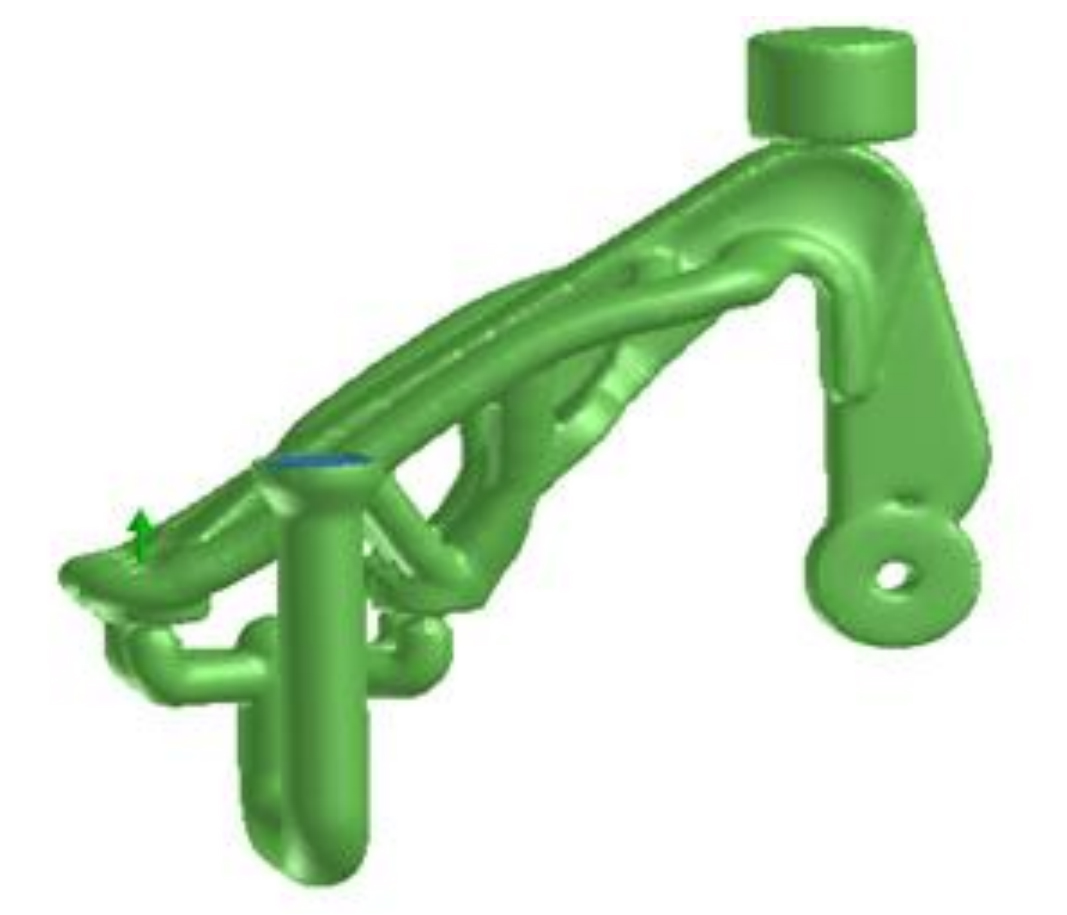

The investment casting shell is made of refractory quartz and the investment casting material is stainless steel. The cooling mode is air cooling. The shell thickness is 4mm, as shown in Figure 3 below. The preheating temperature of the shell is 600 ℃.