Austenite and graphite will precipitate in the solidification process of nodular iron casting. The crystallization of austenite will cause shrinkage, while the crystallization of graphite will cause expansion, that is, expansion will occur in addition to shrinkage in the solidification process, which makes the solidification process of nodular iron casting extremely complex. The characteristics of paste solidification bring great difficulties to the design of casting process.

With the decrease of molten iron temperature of nodular iron casting, the liquid phase volume of ferroalloy is shrinking. Microscopically, the atomic kinetic energy in the ferroalloy system is decreasing, and the atomic spacing is also decreasing. When solidified to the crystallization temperature, the iron atoms crystallize into face centered cubic structure, and the maximum carbon dissolving capacity is 2.11%. People call this non-magnetic solid solution austenite, and austenite is a dense lattice structure with high density. Therefore, The volume shrinkage of austenite liquid iron formed by crystallization is large, and the solidification shrinkage of austenite precipitated from eutectic liquid phase is generally calculated as 3.5%. Therefore, knowing the amount of austenite precipitated, the volume shrinkage caused by austenite precipitated from nodular iron casting can be calculated.

In this process, due to the large amount of precipitation of graphite, the nucleation and growth of graphite ball expand, which counteracts part of the volume shrinkage during the formation of austenite. The density of carbon is about 2.25g/cm3. For every 1% carbon precipitated, the volume of nodular iron casting will expand by 2.05% ~ 3.4%. Therefore, the volume expansion caused by the precipitated graphite can be calculated by calculating the amount of precipitated graphite, which is also the basic logic algorithm of the background of general mold flow software.

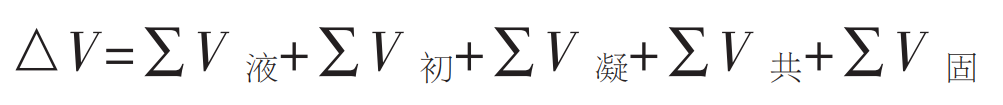

From the above analysis, it can be seen that the volume change of nodular iron casting is the dynamic superposition result of shrinkage and expansion.

Therefore, understanding the volume change of nodular iron casting during solidification can well guide the casting process design, select the appropriate carbon equivalent and pouring temperature, and reduce the shrinkage porosity and shrinkage tendency of ball milled cast iron castings.